W type antimony-based semiconductor laser with gradually varied Ga In proportion

A semiconductor and laser technology, applied in the field of W-type antimony-based semiconductor lasers, can solve the problems of low laser output power, inactive consumption of carriers, and low output power, so as to avoid inactive consumption, reduce non-radiative transitions, and reduce recombination centers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

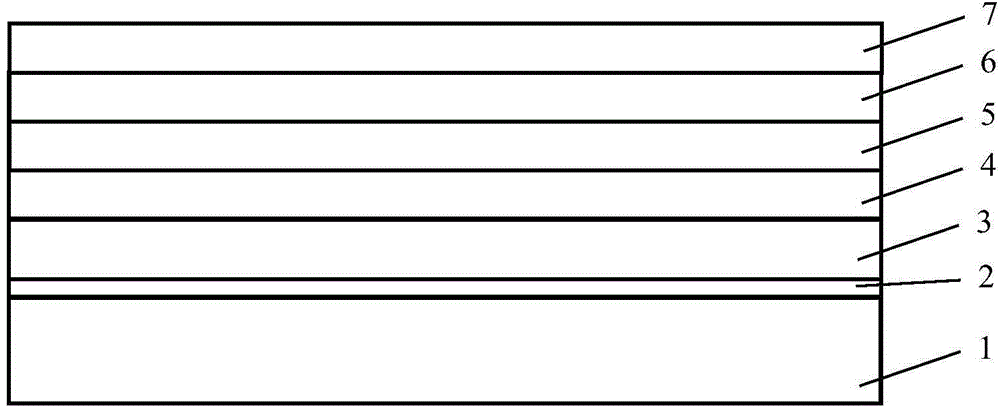

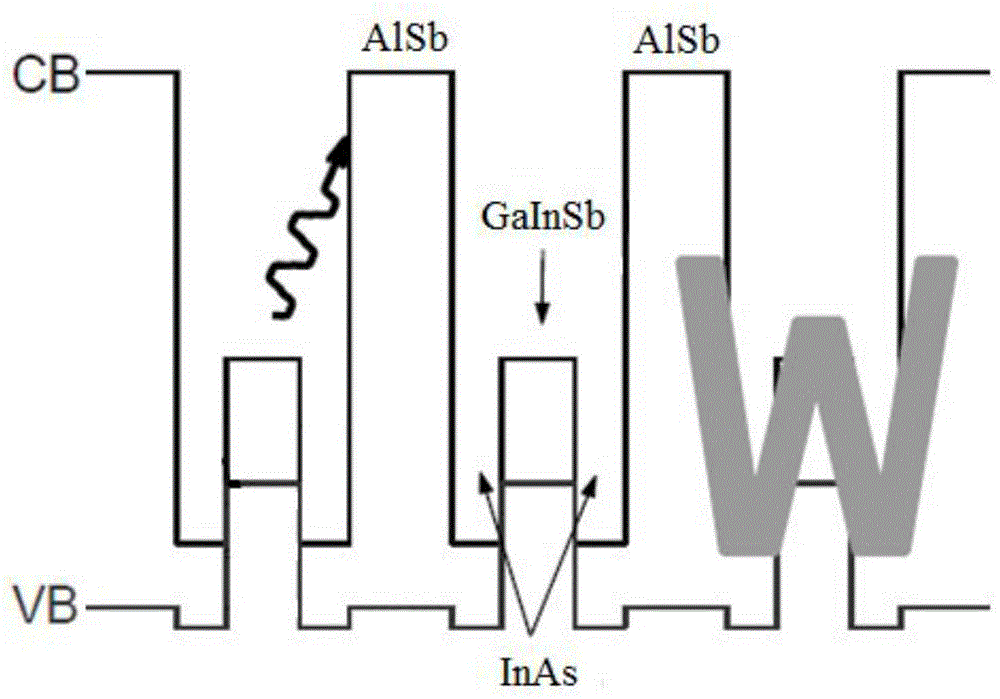

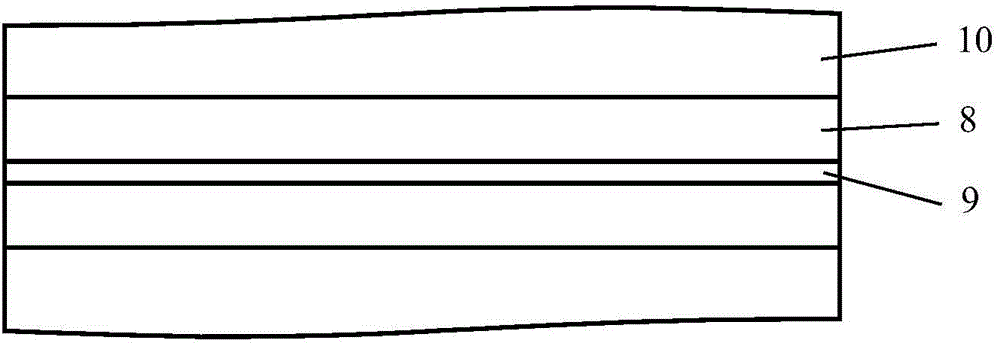

[0010] The W-type antimony-based semiconductor laser with gradually changing Ga In ratio of the present invention, from bottom to top, is GaSb substrate 1, GaSb buffer layer 2, P-type GaSb contact layer 3, P-type quantum well 4, intrinsic quantum well 5, N-type quantum well 6 and N-type InAs contact layer 7, such as figure 1 As shown, the P-type quantum well 4, the intrinsic quantum well 5, and the N-type quantum well 6 have a multi-period structure, and the structure of each single-period quantum well in the multi-period structure is composed of double InAs electron quantum wells 8 A sandwich structure sandwiching GaInSb hole quantum wells 9, the outer layer is a pair of AlSb alloy confinement layers 10, such as figure 2 , image 3 Shown; The GaInSb hole quantum well 9 is made of 3 layers of Ga 1-x In x Composition of Sb layer with 17ML thick Ga in the middle 0.8 In 0.2 Sb layer, level 1 is two 4ML thick Ga 0.9 In 0.1 Sb layer, Ga 1-x In x The total thickness of the...

Embodiment 2

[0012] The W-type antimony-based semiconductor laser with gradually changing Ga In ratio of the present invention, from bottom to top, is GaSb substrate 1, GaSb buffer layer 2, P-type GaSb contact layer 3, P-type quantum well 4, intrinsic quantum well 5, N-type quantum well 6 and N-type InAs contact layer 7, such as figure 1 As shown, the P-type quantum well 4, the intrinsic quantum well 5, and the N-type quantum well 6 have a multi-period structure, and the structure of each single-period quantum well in the multi-period structure is composed of double InAs electron quantum wells 8 A sandwich structure sandwiching GaInSb hole quantum wells 9, the outer layer is a pair of AlSb alloy confinement layers 10, such as figure 2 , image 3 Shown; The GaInSb hole quantum well 9 is made of 5 layers of Ga 1-x In x The Sb layer constitutes as Figure 4 shown, the middle is 17ML thick Ga 0.75 In 0.25 Sb layer, level 1 is two 2ML thick Ga 0.9 In 0.1 Sb layer, level 2 is two 2ML th...

Embodiment 3

[0014] The W-type antimony-based semiconductor laser with gradually changing Ga In ratio of the present invention, from bottom to top, is GaSb substrate 1, GaSb buffer layer 2, P-type GaSb contact layer 3, P-type quantum well 4, intrinsic quantum well 5, N-type quantum well 6 and N-type InAs contact layer 7, such as figure 1 As shown, the P-type quantum well 4, the intrinsic quantum well 5, and the N-type quantum well 6 have a multi-period structure, and the structure of each single-period quantum well in the multi-period structure is composed of double InAs electron quantum wells 8 A sandwich structure sandwiching GaInSb hole quantum wells 9, the outer layer is a pair of AlSb alloy confinement layers 10, such as figure 2 , image 3 Shown; The GaInSb hole quantum well 9 is made of 9 layers of Ga 1-x In x Composition of Sb layer with 17ML thick Ga in the middle 0.65 In 0.35 Sb layer, level 1 is two 1ML thick Ga 0.75 In 0.25 Sb layer, level 2 is two 1ML thick Ga 0.85 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com