Quasi wild ganoderma lipsiense cultivation process

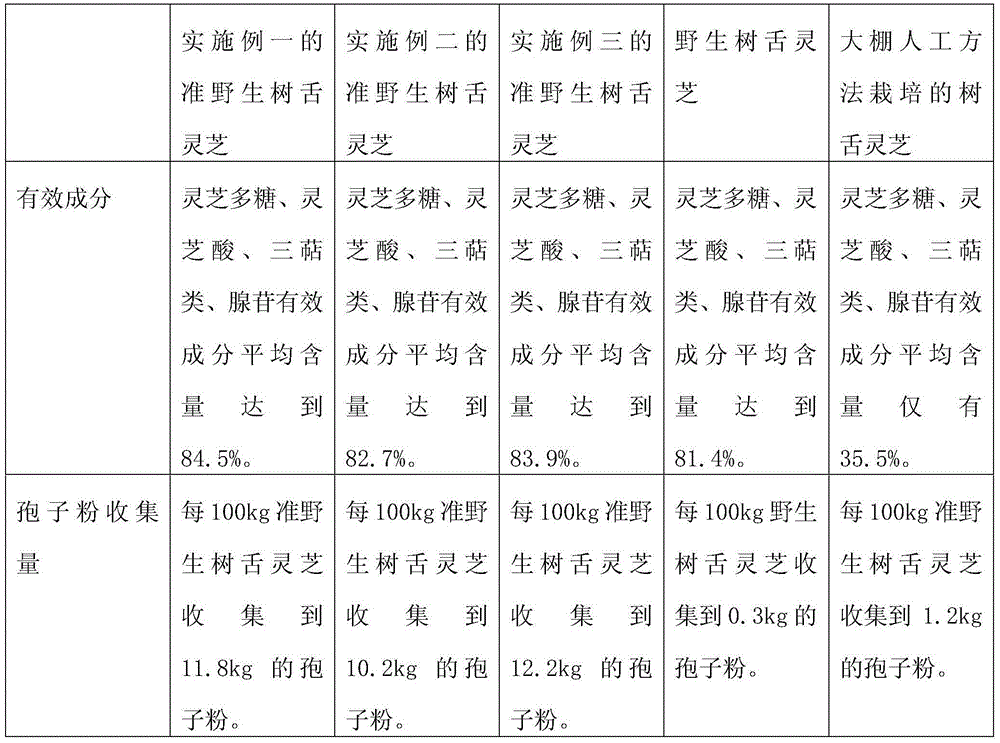

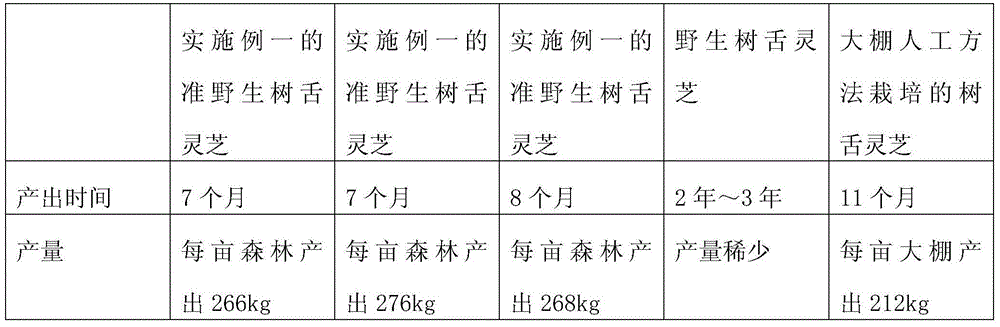

A technology of Ganoderma lucidum and process is applied in the field of quasi-wild Ganoderma lucidum cultivation technology, and can solve the problems that the effect of Ganoderma lucidum cannot reach the effect of wild Ganoderma lucidum, lack of efficacy of wild Ganoderma lucidum, low yield of wild Ganoderma lucidum, etc. , to shorten the cultivation time, facilitate the promotion and increase the income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This quasi-wild ganoderma ganoderma cultivation technique is carried out by the following steps:

[0018] The first step is domestication and cultivation of the mother species. Select triple-distilled water, corn flour, gypsum powder, and elm leaves to make a medium for the mother species in a petri dish, and then divide it into test tubes. The amount of triple-distilled water is 1kg, corn flour The consumption of elm leaves is 7kg, the consumption of elm leaves is 0.5kg, and the content of gypsum powder in the parent medium is 0.2%, wherein the processing of elm leaves is to obtain elm leaf powder after elm leaves are pulverized and screened to put 70 orders, 1.8 Mpa pressure autoclaving for 60 minutes, after cooling, put the test tube of the mother seed medium and wild Ganoderma lucidum into the inoculation box for 40 minutes, and then select the mycelium of the wild Ganoderma lucidum growing on the tree as the strain and insert it into the mother plant The first dome...

Embodiment 2

[0026] This quasi-wild ganoderma ganoderma cultivation technique is carried out by the following steps:

[0027] The first step is domestication and cultivation of the mother species. Select triple-distilled water, corn flour, gypsum powder, and elm leaves to make a culture medium for the mother species in a petri dish, and then divide it into test tubes. The amount of triple-distilled water is 2kg, corn flour The consumption of elm leaves is 8kg, the consumption of elm leaves is 0.6kg, and the content of gypsum powder in the mother plant culture medium is 0.2%, wherein the treatment of elm leaves is to crush and screen elm leaves to obtain elm leaf powder after 70 orders to 90 orders sterilized under 1.8Mpa pressure for 60 minutes, after cooling, put the test tube of the mother culture medium and wild Ganoderma lucidum into the inoculation box for disinfection for 40 minutes, and then select the mycelium of wild Ganoderma lucidum growing on the tree as the inoculation Put it ...

Embodiment 3

[0035] This quasi-wild ganoderma ganoderma cultivation technique is carried out by the following steps:

[0036] The first step is domestication and cultivation of the mother species. Select triple-distilled water, corn flour, gypsum powder, and elm leaves to make a culture medium for the mother species in a petri dish, and then divide it into test tubes. The amount of triple-distilled water is 3kg, corn flour The consumption of elm leaves is 9kg, the consumption of elm leaves is 0.8kg, and the content of gypsum powder in the mother plant culture medium is 0.2%, wherein the processing of elm leaves is to obtain elm leaf powder after elm leaves are pulverized and screened to put 90 orders, 1.8 Mpa pressure autoclaving for 60 minutes, after cooling, put the test tube of the mother seed medium and wild Ganoderma lucidum into the inoculation box for 40 minutes, and then select the mycelium of the wild Ganoderma lucidum growing on the tree as the strain and insert it into the mother...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com