Grain-saving type meat duck compound feed as well as preparation method and using method thereof

A compound feed, grain-saving technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problem of the lack of large potatoes, and achieve the effect of reducing the cost of feeding, reducing the cost of raw materials, and alleviating tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

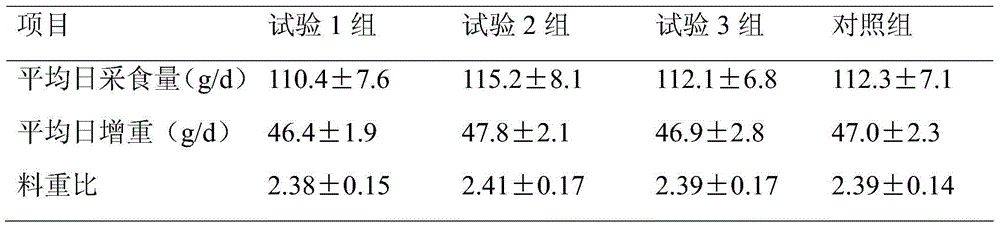

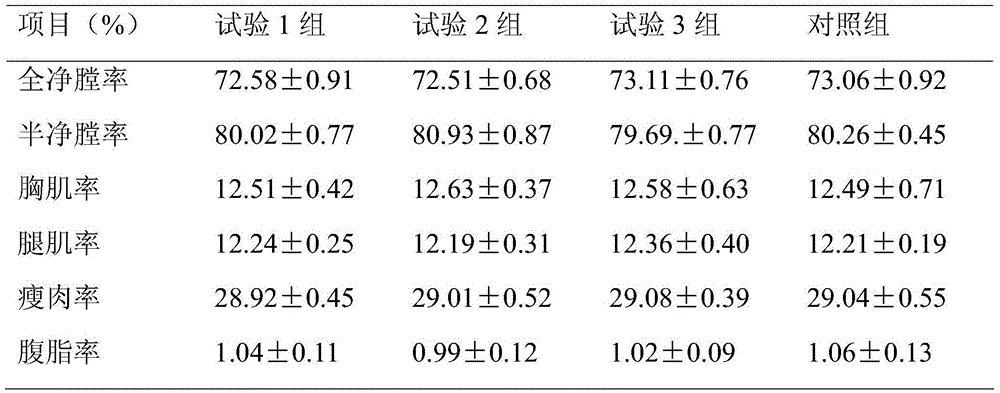

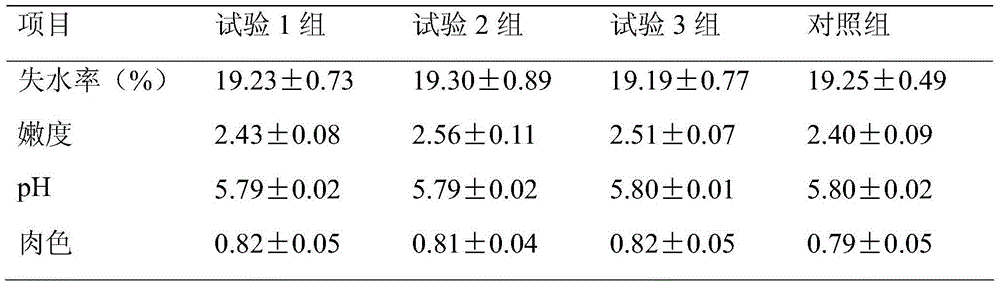

Examples

Embodiment 1

[0028] Prepare No. 1 meat duck feed according to the following steps, specifically as follows:

[0029] S1. Weigh the raw materials according to the following mass percentages: 39.05% corn, 24% potato, 6% wheat bran, 6.7% soybean meal, 9% rapeseed meal, 9% cottonseed meal, 3% rice bran, 0.1% methionine, lysine 0.5%, table salt 0.35%, calcium hydrogen phosphate 1%, stone powder 0.9%, choline chloride 0.1%, vitamin premix 0.1%, trace element premix 0.2%; mix the raw materials in the mixer for 150-210 seconds , and then crush the uniformly mixed raw materials through a 1.5-2.2mm sieve;

[0030] S2. Preparing the pulverized raw material in a steam conditioner at 85-95°C for 3-5 minutes, and then making the prepared raw material into granules under the condition of 90-100°C;

[0031] S3. Dry the granular feed at 75-90° C., cool it, and pack it into bags.

Embodiment 2

[0033] Prepare No. 2 meat duck feed according to the following steps, specifically as follows:

[0034] S1. Weigh the raw materials according to the following mass percentages: 37.05% corn, 26% potato, 6% wheat bran, 6.7% soybean meal, 9% rapeseed meal, 9% cottonseed meal, 3% rice bran, 0.1% methionine, lysine 0.5%, table salt 0.35%, calcium hydrogen phosphate 1%, stone powder 0.9%, choline chloride 0.1%, vitamin premix 0.1%, trace element premix 0.2%; mix the raw materials in the mixer for 150-210 seconds , and then crush the uniformly mixed raw materials through a 1.5-2.2mm sieve;

[0035] S2. Preparing the pulverized raw material in a steam conditioner at 85-95°C for 3-5 minutes, and then making the prepared raw material into granules under the condition of 90-100°C;

[0036] S3. Dry the granular feed at 75-90° C., cool it, and pack it into bags.

Embodiment 3

[0038] Prepare No. 3 meat duck feed according to the following steps, specifically as follows:

[0039] S1. Weigh the raw materials according to the following mass percentages: 35.05% corn, 28% potato, 5.7% wheat bran, 7% soybean meal, 9% rapeseed meal, 9% cottonseed meal, 3% rice bran, 0.1% methionine, lysine 0.5%, table salt 0.35%, calcium hydrogen phosphate 1%, stone powder 0.9%, choline chloride 0.1%, vitamin premix 0.1%, trace element premix 0.2%; mix the raw materials in the mixer for 150-210 seconds , and then crush the uniformly mixed raw materials through a 1.5-2.2mm sieve;

[0040] S2. Preparing the pulverized raw material in a steam conditioner at 85-95°C for 3-5 minutes, and then making the prepared raw material into granules under the condition of 90-100°C;

[0041] S3. Dry the granular feed at 75-90° C., cool it, and pack it into bags.

[0042] In the above-mentioned Examples 1-3, the vitamin premix includes the following components in mass percentage: vitamin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com