A method for producing upgraded oil from oil sands and co-producing steam

A technology for oil sand and steam, which is applied in the field of oil sand production, modified oil and co-production of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Example: Comprehensive Utilization of Oil Sands in Xinjiang

[0012] The property data of oil sands in a block in Xinjiang are as follows: asphaltenes 9.55w%, moisture 1.55w%, minerals 88.9w%.

[0013] After the fresh oil sand material is crushed, the bulk density is 1.37g / cm 3 , particle density, 2250kg / m 3 , angle of repose, 38°. It enters the fluidized bed reactor through the feeder, and there are two other materials in the lower part of the reactor, high-temperature circulating gravel at 700°C, and circulating asphalt at 350°C. The three materials are mixed and contacted in the reactor. contact reaction under conditions.

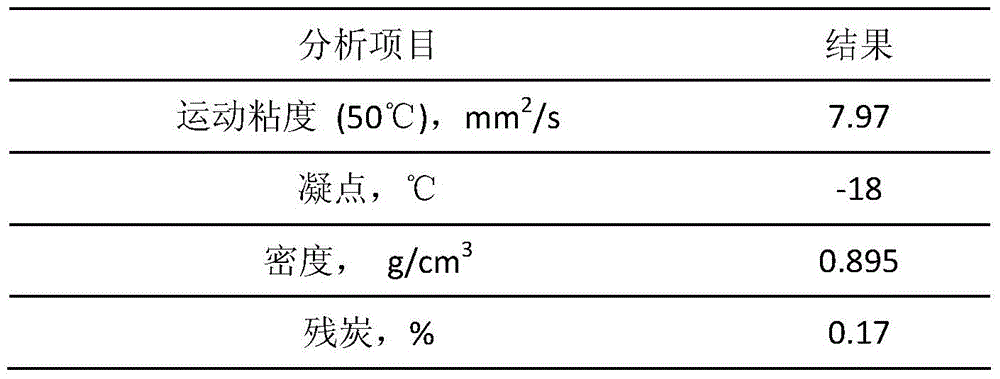

[0014] In this treatment process, the sand and gravel circulation rate / fresh oil sand feed is controlled to be 6, 50% of the fractionation tower bottom residue (fraction above 500°C) is returned to the reactor, and the remaining fractions are blended to obtain upgraded oil. The product distribution data after normalization is: gas 6.5w%, modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com