A kind of light hydrocarbon oil catalytic conversion method

A catalytic conversion method and a technology for hydrocarbon oil are applied in the field of catalytic conversion of light hydrocarbon oil to produce low-carbon olefins, which can solve the problems of rapid deactivation of catalysts, difficulty in realizing high temperature reaction, and high conversion rate of cracking reaction, and can solve the problems of petrochemical raw materials. The effect of shortage, reducing the total surface area of heat dissipation, and improving the yield of light olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

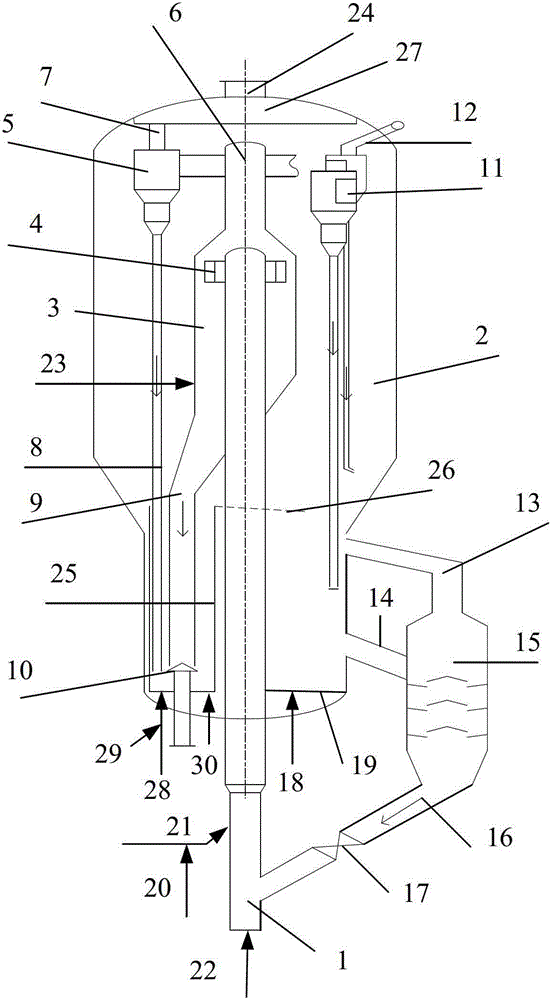

[0106] This embodiment is tested according to the flow process of the accompanying drawing, using straight-run naphtha as raw material, the test is carried out on the medium-sized device of the riser reactor, the preheated raw material oil enters the bottom of the riser, and at a reaction temperature of 675 ° C and a reaction time 2 seconds, the weight ratio of the catalytic cracking catalyst to the raw oil is 25, and the weight ratio of the water vapor to the raw oil is 0.55 to carry out the cracking reaction, and the reaction product, water vapor and the raw catalyst enter the closed cyclone from the reactor outlet, The reaction product and the catalyst are quickly separated, and the reaction product is cut according to the distillation range in the separation system after exchanging heat with the raw material, so as to obtain fractions such as dry gas, propylene, C4 and gasoline. The spent catalyst enters the regenerator under the action of gravity and contacts with air for ...

Embodiment 2

[0109] Using the reaction device, test method and raw materials of Example 1, the difference is that the reaction product oil gas is cut according to the distillation range through the separation system to obtain fractions such as dry gas, propylene, C4 and gasoline, wherein C4 returns to the reactor for further cracking For ethylene and propylene. The operating conditions and product distribution are listed in Table 2.

[0110] It can be seen from Table 2 that the yield of ethylene can reach 25.73% by weight, the yield of propylene can reach 27.68% by weight, and the ratio of propylene / ethylene is about 1.08.

[0111] Table 1

[0112] Raw oil properties

Density (20℃), g / cm 3

0.7358

Vapor pressure / kPa

50.0

Family composition / weight%

Paraffins

51.01

Naphthenic

38.24

Olefin

0.12

Aromatics

10.52

Distillation range, ℃

IBP

46

10%

87

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com