Energy-saving device and energy-saving method for low-calorific-value fuel gas heating furnace

An energy-saving device and fuel gas technology, applied in the direction of combustion methods, furnace control devices, lighting and heating equipment, etc., can solve the problems of reducing the exhaust gas temperature of tube furnaces, the exhaust gas temperature cannot be further reduced, and the efficiency is low, and achieve Reduced heat transfer area, high reliability, and reduced flue gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

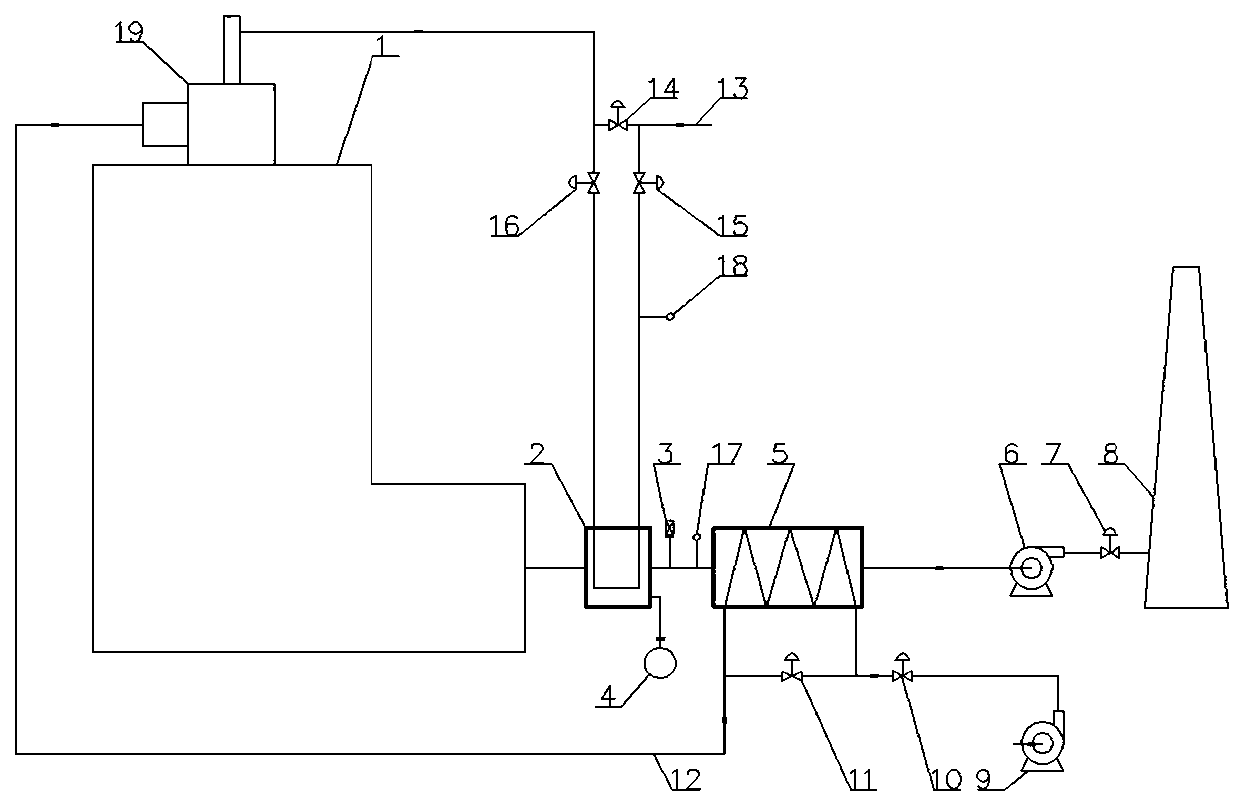

[0026] As shown in the figure, a low calorific value fuel gas heating furnace energy-saving device includes a heating furnace 1, a burner 18 arranged on the top of the heating furnace 1, and a fuel gas preheater 2 arranged at the flue gas outlet of the heating furnace 1. The fuel gas preheater 2 is provided with a fuel gas inlet pipeline and a fuel gas outlet pipeline, and a fuel gas auxiliary line pipeline is also provided between the fuel gas inlet pipeline and the fuel gas outlet pipeline, and the fuel gas auxiliary line The line pipeline directly sends the fuel from the fuel gas inlet pipeline to the burner 19, and also includes an air preheater 5 arranged at the flue gas outlet of the fuel gas preheater 2, and the flue gas outlet of the air preheater 5 is provided with A flue gas induced draft fan 6, the outlet of the flue gas induced draft fan 6 is provided with a flue gas discharge chimney 8, the fuel gas outlet pipeline is connected with the burner 19, the fuel gas inle...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is that the detection element for avoiding flue gas dew point corrosion is arranged on the outer wall surface of the heat exchange element of the fuel gas preheater 1 and is also provided with a wall surface thermometer 4, and a wall surface thermometer 4 When the trigger temperature is lower than the temperature limit value, the valve 14 of the secondary pipeline of the fuel burner is triggered to open. The temperature limit value is the flue gas dew point temperature T~T+50°C. At the same time, the fuel gas inlet valve 15 and the fuel gas outlet valve 16 are closed. The fuel gas enters the heating furnace 1 through the fuel gas sub-line valve 14 to burn, so as to avoid dew point corrosion failure of the heat exchange element of the fuel gas preheater 2, resulting in fuel gas leakage, and fuel leakage of the fuel gas preheater caused by flue gas dew point corrosion Surveillance, prevention and treatment.

Embodiment 3

[0036] In embodiment 3, the fuel gas temperature measuring instrument 18, the flue gas temperature measuring instrument 17 and the wall surface thermometer 4 are set at the same time, and the gas leakage alarm device 3 is set at the same time, which plays the role of triple protection at the same time, avoiding fuel gas preheating. The dew point corrosion failure of the heat exchange element of Heater 2 leads to fuel gas leakage, which is used for the monitoring, prevention and disposal of fuel gas preheater fuel leakage caused by flue gas dew point corrosion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com