Feeder for scrap rubber cracking still

A technology of feeding device and cracking kettle, which is used in plastic recycling, special form dry distillation, preparation of liquid hydrocarbon mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

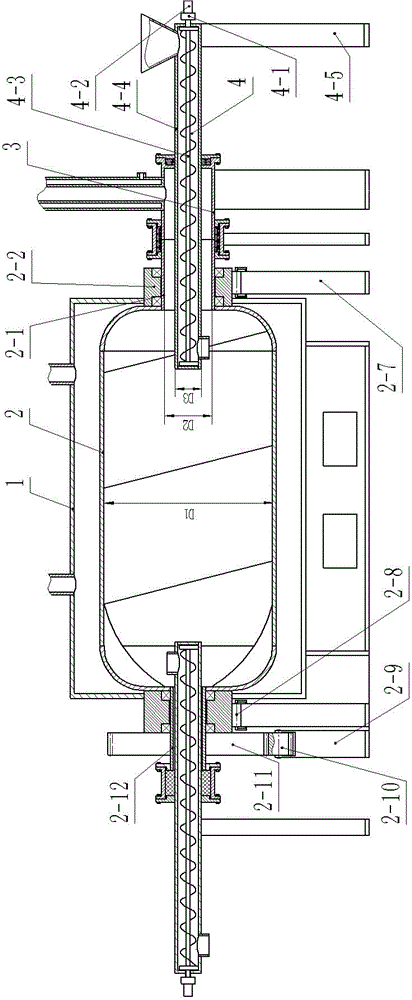

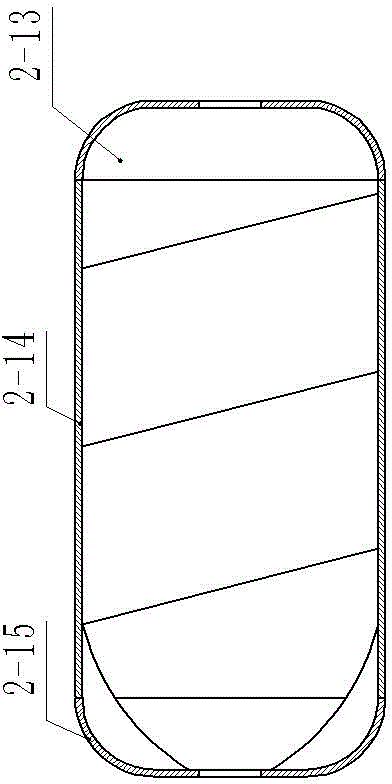

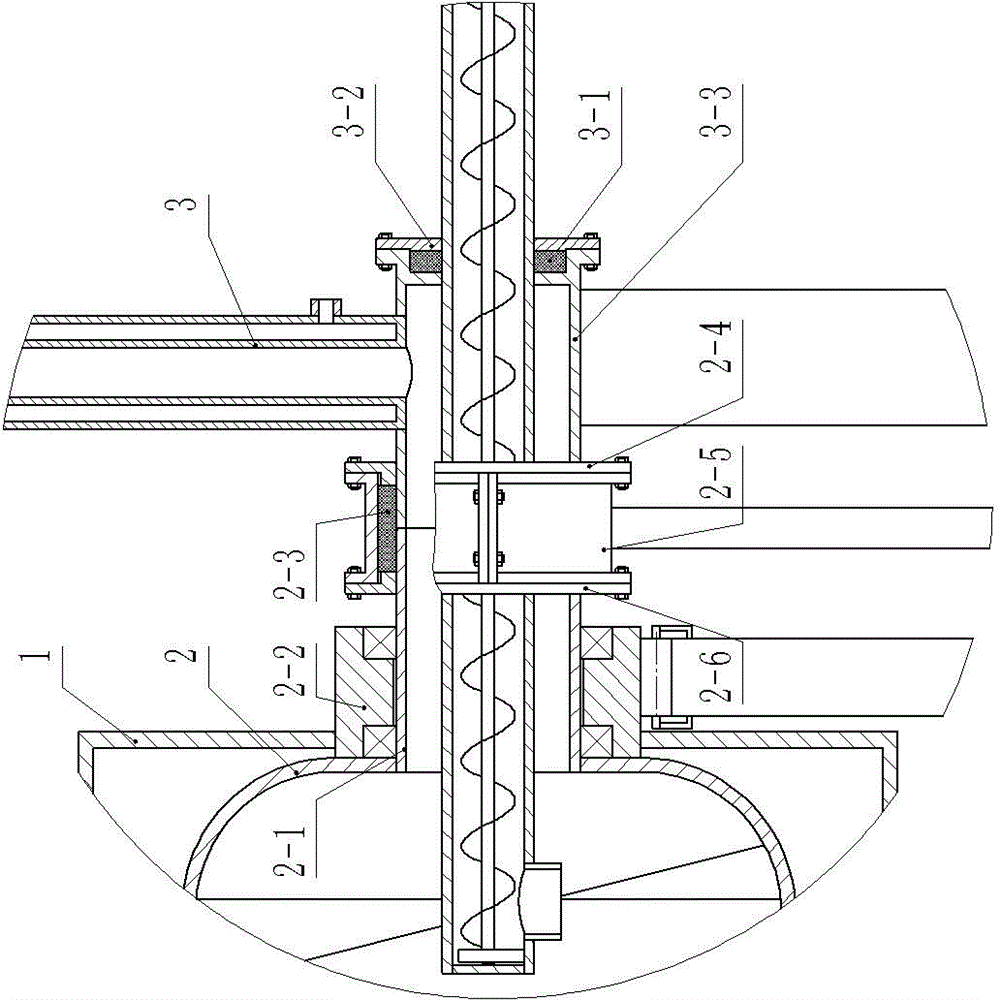

[0013] Such as figure 1 , figure 2 and image 3 The shown waste rubber cracking kettle includes a kettle body 2 driven by a rotary drive device. The kettle body 2 is composed of a cylinder body 2-14 and a head welded at both ends of the cylinder body 2-14. The heads at both ends are respectively Feed end cap 2-13, discharge end cap 2-15; a discharge hollow shaft 2-12 is welded at the center of the discharge end cap 2-15, and a discharge hollow shaft 2-12 is welded at the center of the feed end cap 2-13 The feed hollow shaft 2-1 is welded; the rotary drive device includes a large gear 2-11 mounted on the discharge hollow shaft 2-12, the large gear 2-11 is meshed with the pinion 2-10, and the pinion 2-10 The pinion shaft is mounted on the gear frame 2-9; the pinion shaft is connected with the drive motor through a reducer (not shown in the figure); the kettle body 2 is respectively set on the discharge hollow shaft 2-12 and the feed hollow Two bearing rings 2-2 on the shaft ...

Embodiment 2

[0016] The gas outlet width D2-D3 of the oil-gas delivery channel is equal to 0.315 times the inner diameter D1 of the cylinder body 2-14, that is, 0.315D1, and other features are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com