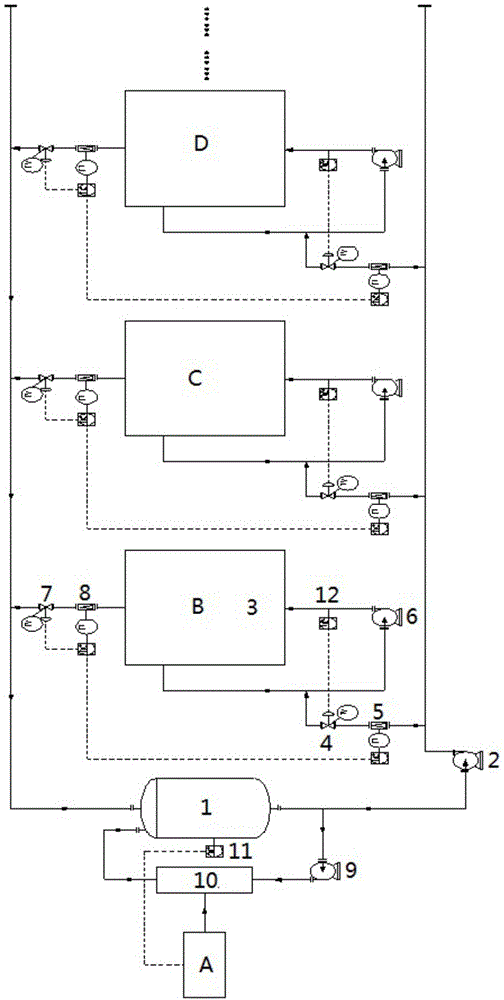

Multistage matching energy supply device and process

A technology for energy supply and equipment, applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve problems such as inability to meet production requirements, unstable system operation, equipment damage, etc., to achieve a wide range of applications and maintain stability performance, and the effect of reducing the number of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The energy supply medium is heat conduction oil. After the heat conduction oil is filled in the system, firstly turn on the forced circulation pump 9 of the energy supply equipment, use the energy exchange equipment 10 to heat the heat conduction oil, and then return to the energy supply medium storage tank 1, through the energy supply The medium temperature transmitter 11 controls, and after the heat transfer oil reaches the temperature set by the system of 250°C, the energy supply medium pump 2 is turned on to deliver the heat transfer oil to each user.

[0037] Assuming that user one B is a heat exchanger, the temperature of the heat exchange medium is required to be controlled at 150°C. The heat transfer oil enters the tube side of the heat exchanger. Through the user's forced circulation pump 6, the heat transfer oil is fully mixed and the temperature is uniform. Through the user's temperature transmitter 12, set the target temperature as 150°C. The temperature c...

Embodiment 2

[0041] The energy supply medium is hot water. After the hot water is filled in the system, the hot water forced circulation pump 9 is first turned on, and the waste heat recovery heat exchanger 10 of the system is used to raise the temperature of the hot water, and then returns to the hot water tank 1. Controlled by the water temperature transmitter 11, when the hot water reaches the system-set temperature of 90° C., the hot water pump 2 is turned on to deliver the hot water to each user.

[0042] Assuming that user one B is a fermentation tank, the temperature of the material in the tank is required to be controlled at 45°C. The hot water enters the hot water jacket of the fermentation tank, and the fermentation is carried out at a constant temperature. The forced circulation pump 6 through the heat exchanger makes the hot water fully mixed and the temperature uniform. Through the heat exchanger temperature transmitter 12, considering a certain temperature difference between...

Embodiment 3

[0046] The energy supply medium is ethylene glycol. After the ethylene glycol is filled in the system, the ethylene glycol forced circulation pump 9 is first turned on, and the Freon compressor 10 is used to cool the ethylene glycol for heat exchange, and then return to the ethylene glycol tank 1 , controlled by the ethylene glycol temperature transmitter 11, after the ethylene glycol reaches the temperature set by the system -15°C, the ethylene glycol pump 2 is turned on, and the ethylene glycol is delivered to each cooling user.

[0047] Let User 1B be a heat exchanger, which cools the water to 10°C, and the heat exchange temperature is required to be controlled above 0°C. Ethylene glycol enters the tube side of the heat exchanger. Through the forced circulation pump 6 of the heat exchanger, the ethylene glycol is fully mixed and the temperature is uniform. Through the heat exchanger temperature transmitter 12, set the target temperature as 1°C. The temperature control val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com