A method for controlling needle marks in wafer high temperature testing

A wafer, high-temperature technology, applied in the direction of electronic circuit testing, components of electrical measuring instruments, measuring electricity, etc., can solve the problems of affecting the effect of needle marks and unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

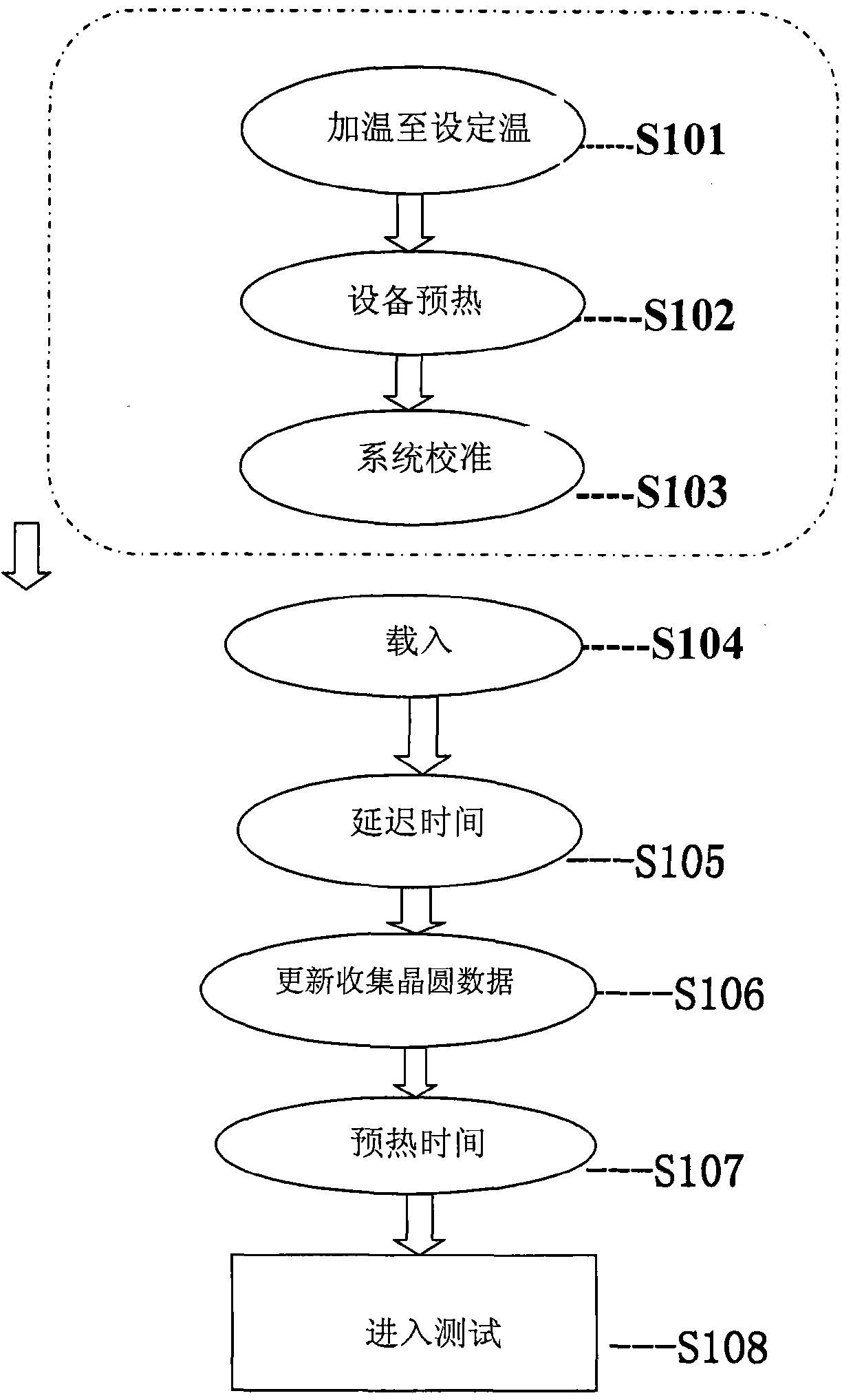

[0014] refer to figure 1 The steps shown, S101-S103 are the preparatory work before the high-temperature test, as long as the high-temperature test state is not changed after being set once, there is no need to redo the process again. First, step S101 is heating to a set temperature. That is to say, the equipment is heated up to the set temperature of high temperature, there may be a difference of two degrees, and the heating time is 6 minutes. During the heating process, the position of the slide table should be moved to the initial position. Next, step S102 is to preheat the equipment. After heating up to the set temperature, the equipment is left to stand for 120 minutes, the purpose of which is to establish a high-temperature environment inside the equipment, so that the alignment calibration step can reach a stable state under the high-temperature environment. Then, step S103 is a system calibration step, that is, after preheating, the accuracy of each part of the probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com