Mobile wireless debugging terminal of cnc system of six-axis CNC polishing machine and its operation method

A polishing machine, mobile technology, applied in the general control system, control/regulation system, digital control, etc., can solve the problems of increased personnel costs and low work efficiency, reduce the requirements for professional knowledge and academic qualifications, and improve programming and debugging The effect of efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

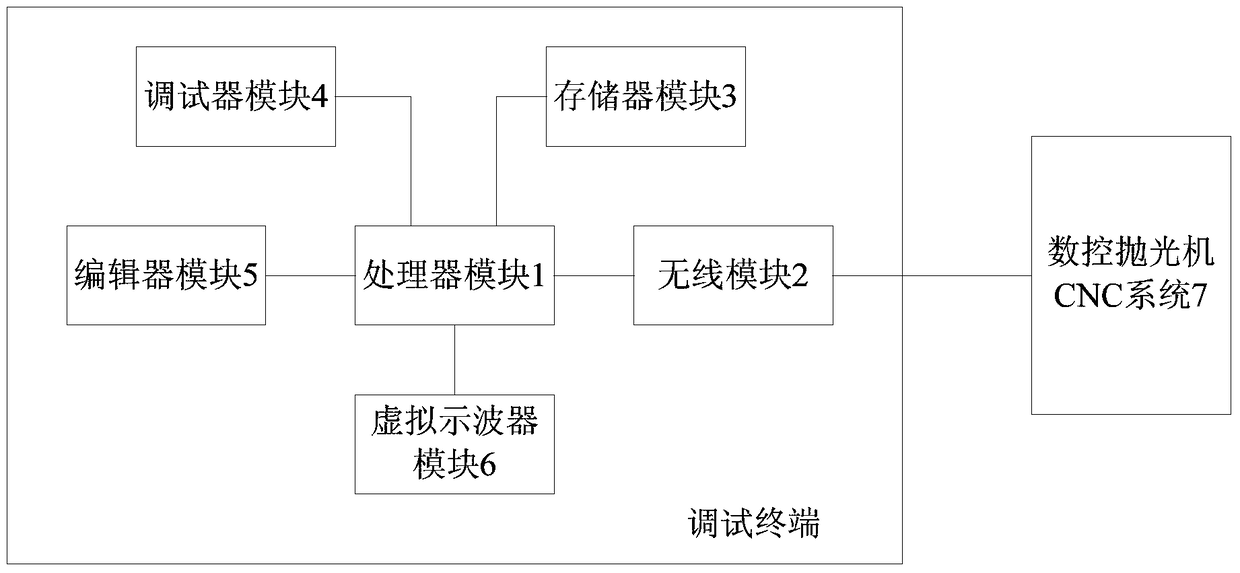

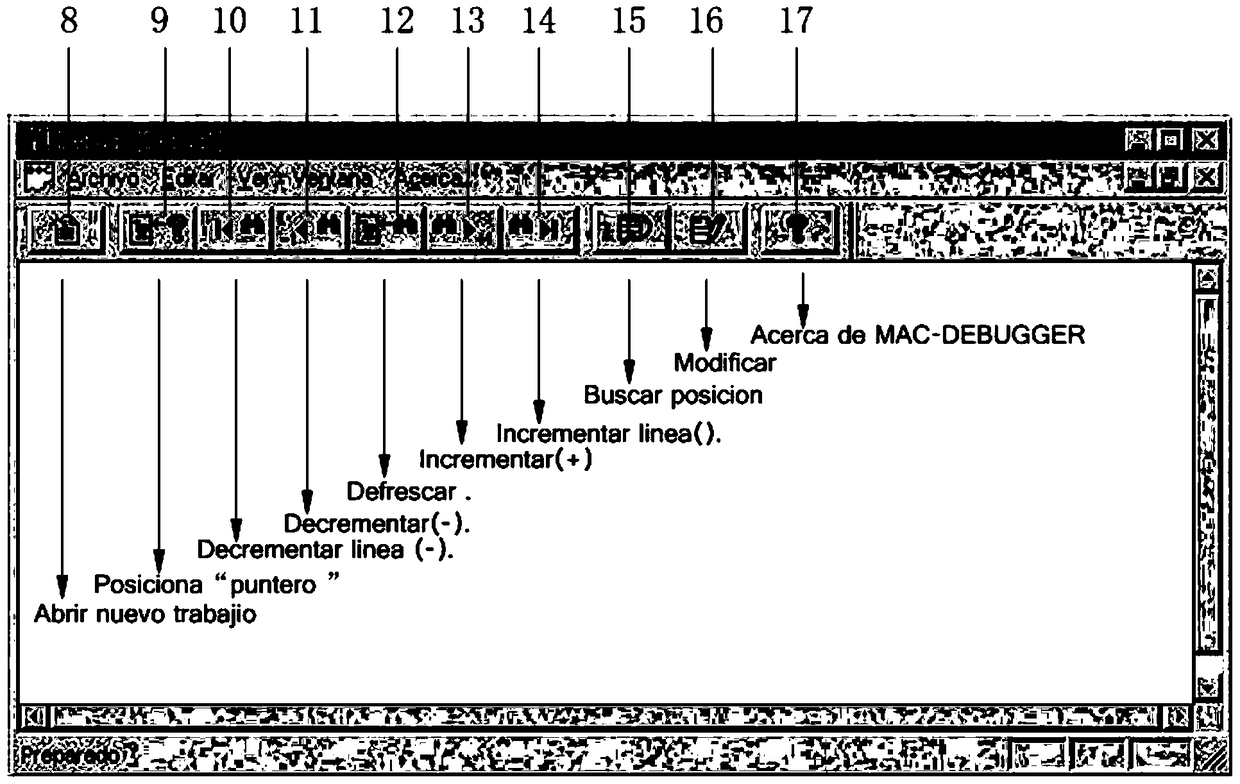

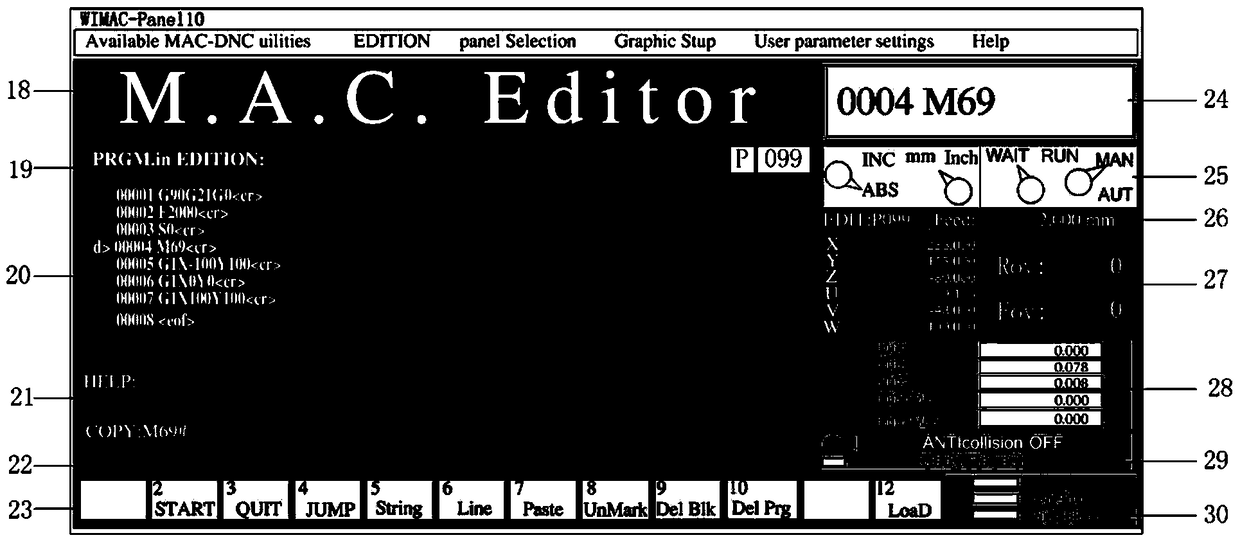

[0032] Such as figure 1 As shown, the mobile wireless debugging terminal of the six-axis CNC polishing machine CNC system of the present invention includes a debugging terminal body, and the debugging terminal body includes a processor module 1, a wireless module 2, a memory module 3, and a debugger module 4. Editor module 5 and virtual oscilloscope module 6, above-mentioned memory module 3, debugger module 4, editor module 5 and virtual oscilloscope module 6 are respectively connected with processor module 1, and processor module 1 communicates with six through wireless module 2 The CNC system 7 of the axis CNC polishing machine is connected to the signal, so as to provide a direct man-machine dialogue channel between the operator and the CNC machine. Further, the processor module is based on the Windows operating system, the wireless module includes a Bluetooth communication interface, the editor module uses an 8-axis control program editor, and the virtual oscilloscope modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com