Pressure-swing adsorbent regeneration control device and control method thereof

A technology for regeneration and regeneration control of adsorbents, applied in separation methods, filter regeneration, comprehensive factory control, etc., which can solve the problems of low energy consumption, high energy consumption, and residues in the washing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

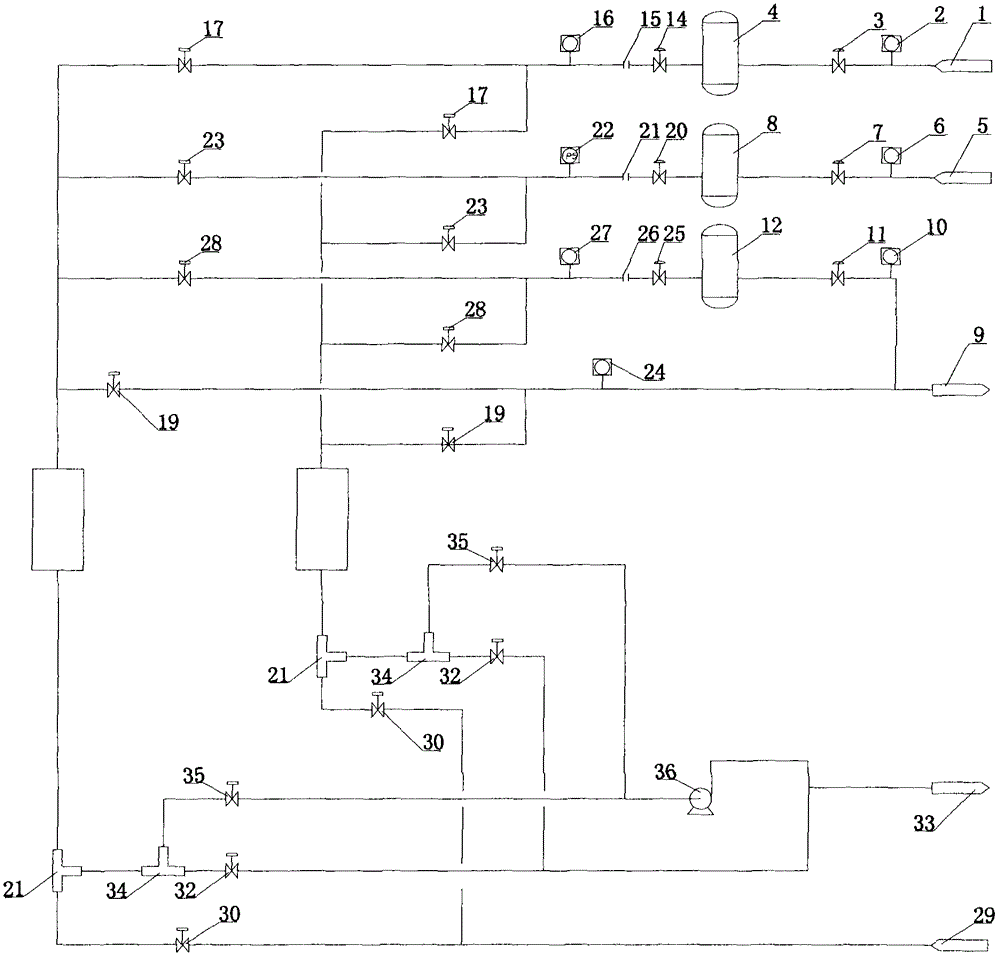

Method used

Image

Examples

Embodiment 1

[0064] The present invention adopts the nitrogen flushing regeneration method to regenerate the adsorption tower unit adsorbent regeneration, including the following steps:

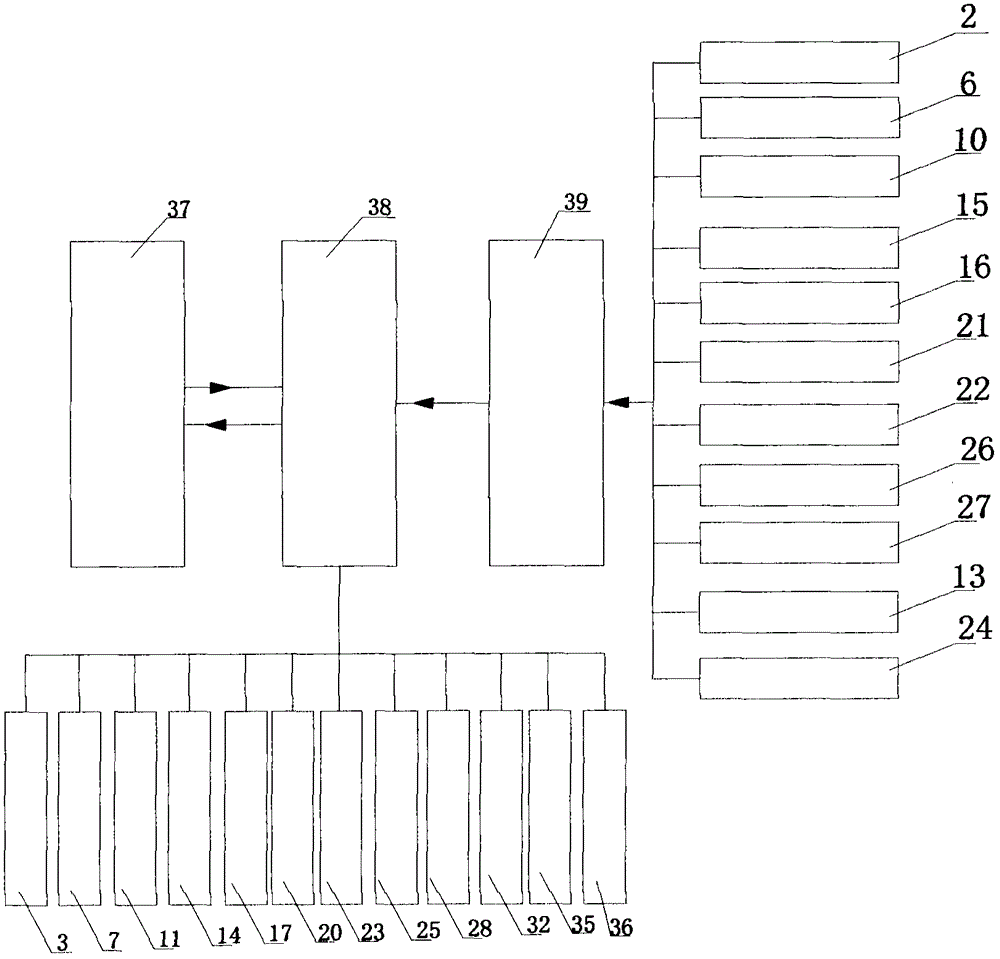

[0065] Step 1: In the preparation stage for nitrogen flushing, when the nitrogen inlet pressure sensor 2 detects that the nitrogen pressure is between 0.2 and 0.4 MPa, the nitrogen inlet pressure sensor 2 will feed back the detected nitrogen pressure to the DCS database 39 and the DCS main control card 38. The model predictive controller 37, the model predictive controller 37 controls the opening of the nitrogen gas intake regulating valve 3 and the nitrogen flushing regulating valve 14 through the DCS main control card 38; the opening of the nitrogen gas intake regulating valve 3 is 80%, and the nitrogen flushing regulating valve 14 The opening is 80%, the nitrogen flow is 4000Nm 3 / h;

[0066] Step 2: Enter the nitrogen flushing stage. When the nitrogen gas intake regulating valve 3 and the nitrogen fl...

Embodiment 2

[0071] The present invention adopts the nitrogen flushing regeneration method to regenerate the adsorption tower unit adsorbent regeneration, including the following steps:

[0072] Step 1: In the preparation stage for nitrogen flushing, when the nitrogen inlet pressure sensor 2 detects that the nitrogen pressure is between 0.2 and 0.4 MPa, the nitrogen inlet pressure sensor 2 will feed back the detected nitrogen pressure to the DCS database 39 and the DCS main control card 38. The model predictive controller 37, the model predictive controller 37 controls the opening of the nitrogen gas intake regulating valve 3 and the nitrogen flushing regulating valve 14 through the DCS main control card 38; the opening of the nitrogen gas intake regulating valve 3 is 80%, and the nitrogen flushing regulating valve 14 The opening is 80%, the nitrogen flow is 4000Nm 3 / h;

[0073] Step 2: Enter the nitrogen flushing stage. When the nitrogen gas intake regulating valve 3 and the nitrogen flus...

Embodiment 3

[0080] The present invention adopts the hydrogen flushing regeneration method to regenerate the adsorption tower unit adsorbent regeneration, including the following steps:

[0081] Step 1: In the hydrogen flushing preparation stage, when the hydrogen intake pressure sensor 6 detects that the hydrogen pressure is between 0.2 and 0.4 MPa, the hydrogen intake pressure sensor 6 will feed back the detected hydrogen pressure to the DCS database 39 and the DCS main control card 38. The model predictive controller 37, the model predictive controller 37 controls the opening of the hydrogen gas intake regulating valve 7 and the hydrogen flushing regulating valve 20 through the DCS main control card 38, the opening of the hydrogen gas intake regulating valve 7 is 80%, and the hydrogen flushing regulating valve The opening degree of 20 is 80%, and the flow rate of hydrogen is 3200Nm 3 / h;

[0082] Step 2: Enter the stage of hydrogen flushing. When the hydrogen intake regulating valve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com