Manufacture method of hemispherical luneberg lens antenna

A Lumber lens antenna and lens antenna technology, applied in the field of communication, can solve the problems of difficult control of dielectric constant tolerance, dielectric constant fluctuation, product performance and expected deviation, etc., achieve good social and economic benefits, simple production process, The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

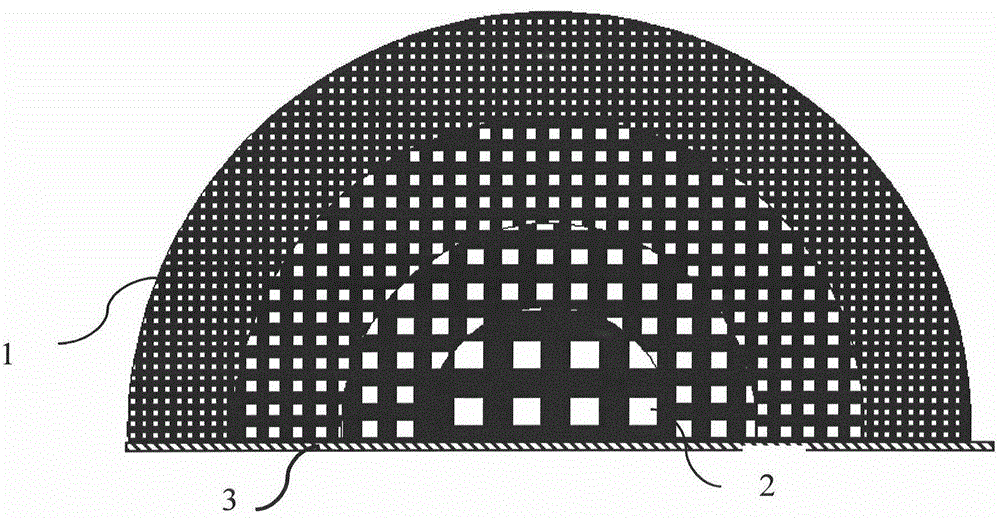

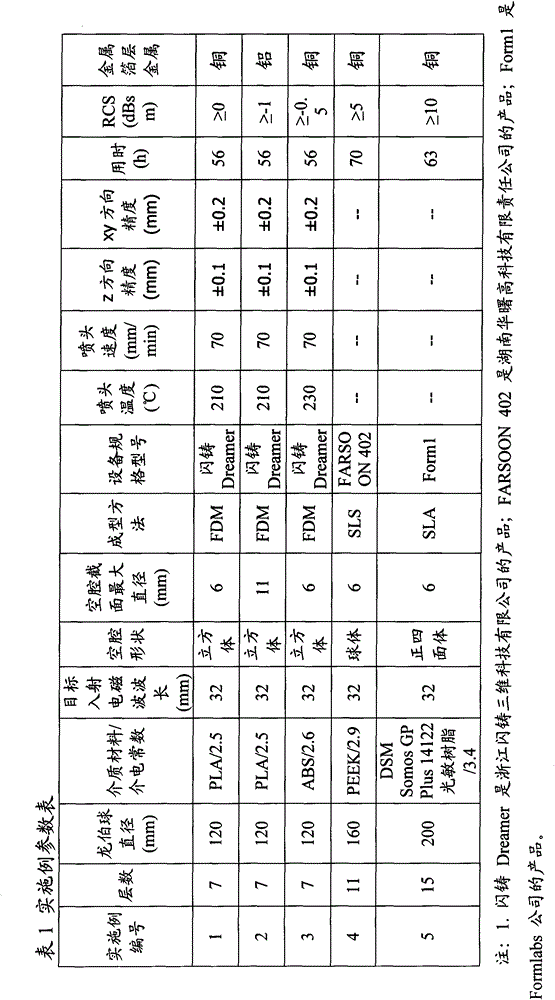

[0081] The hemispherical Lunberg lens antenna made in this embodiment is a hemisphere, in which cavities are distributed, the radius R of the sphere is 60mm, the target RCS value is greater than or equal to 0dBsm, the target incident electromagnetic wave is 9.4GHz, the wavelength is 32mm, and the cavity is A regular hexahedron with a side length of 3.5 mm and a metal foil layer thickness of 0.2 mm.

[0082] In this embodiment, PLA is selected as the material for making the hemispherical Lunberg lens antenna, and its dielectric constant is 2.5. Then use the formula ε i =2-(r i / R) 2 Calculate the dielectric constant of each concentric layer; then calculate the cavity volume fraction of each concentric layer according to the following formula: the average dielectric constant of each concentric layer=[the dielectric constant of this concentric layer material × (1-all in this concentric layer cavities in the concentric layer) + the dielectric constant of the cavity medium × the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com