Split-type detonation fracture splitting machining technology of laser initiation of connecting rod tip

A connecting rod big-end, split-type technology, applied in the field of laser-initiated detonation cracking processing technology, can solve the problems of high requirements for equipment and processing conditions, low cracking efficiency, and high processing costs, saving processing equipment and cracking. The effect of high efficiency and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] A detonation cracking processing technology of laser detonation at the large end of a split connecting rod, comprising the following steps:

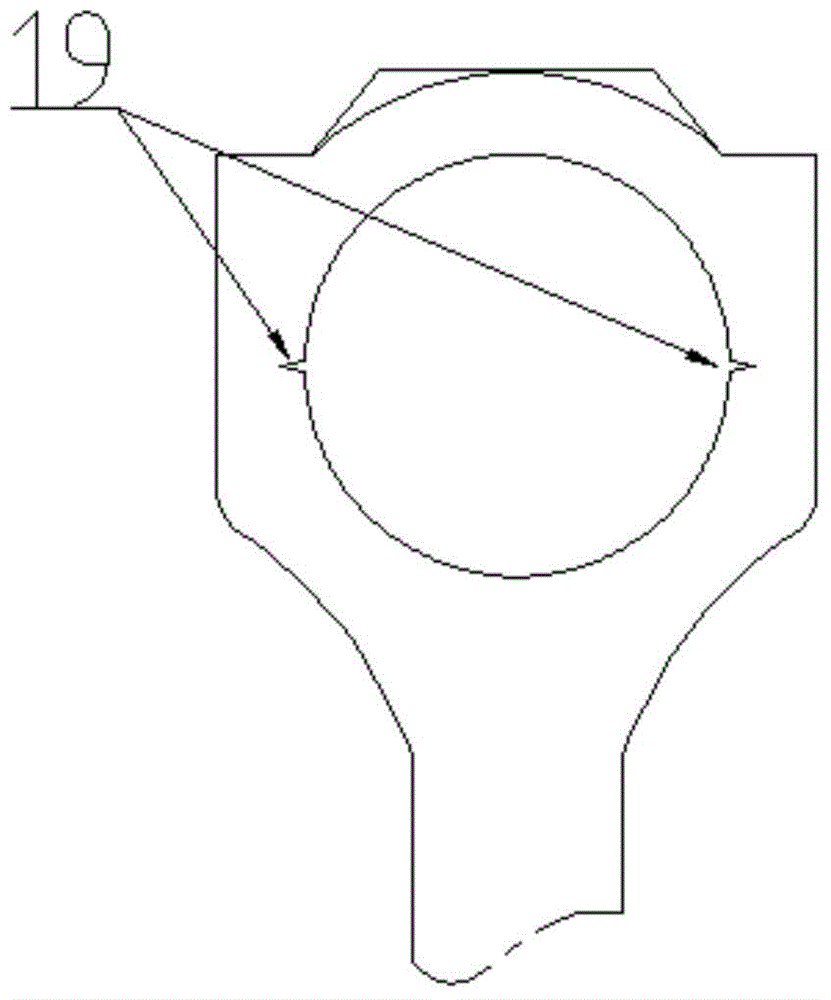

[0024] Step 1. Refer to figure 1 , two cleavage grooves 19 are machined by a broach or laser on the inside of the big head hole of the connecting rod 8. The cleavage groove 19 is sharp-angled and deep groove-shaped, with a depth of 0.4-0.6mm, an opening angle of 0-90°, and a sharp-angle curvature radius of 0.1- 0.3mm;

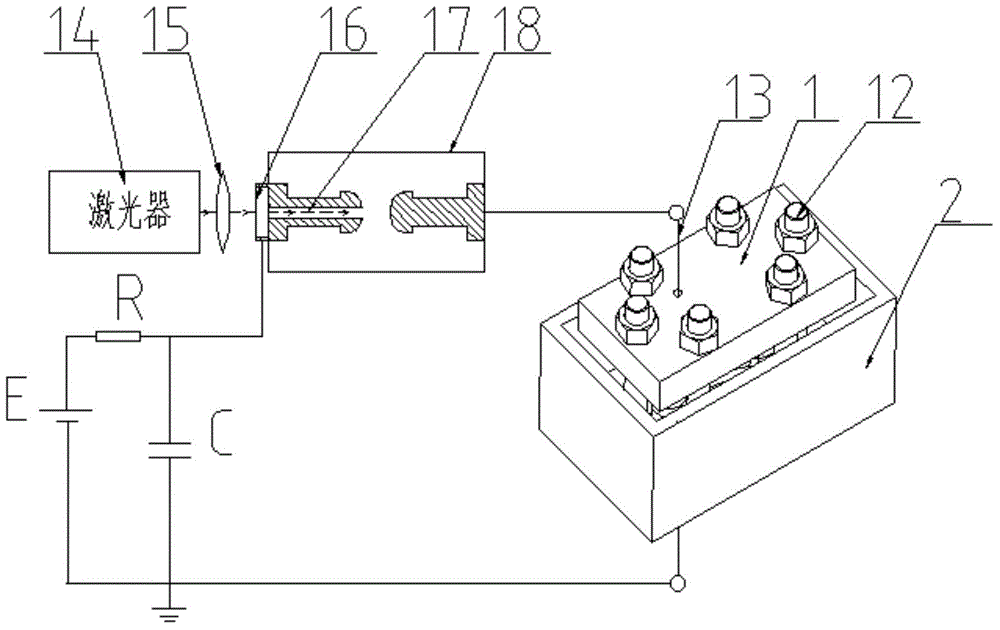

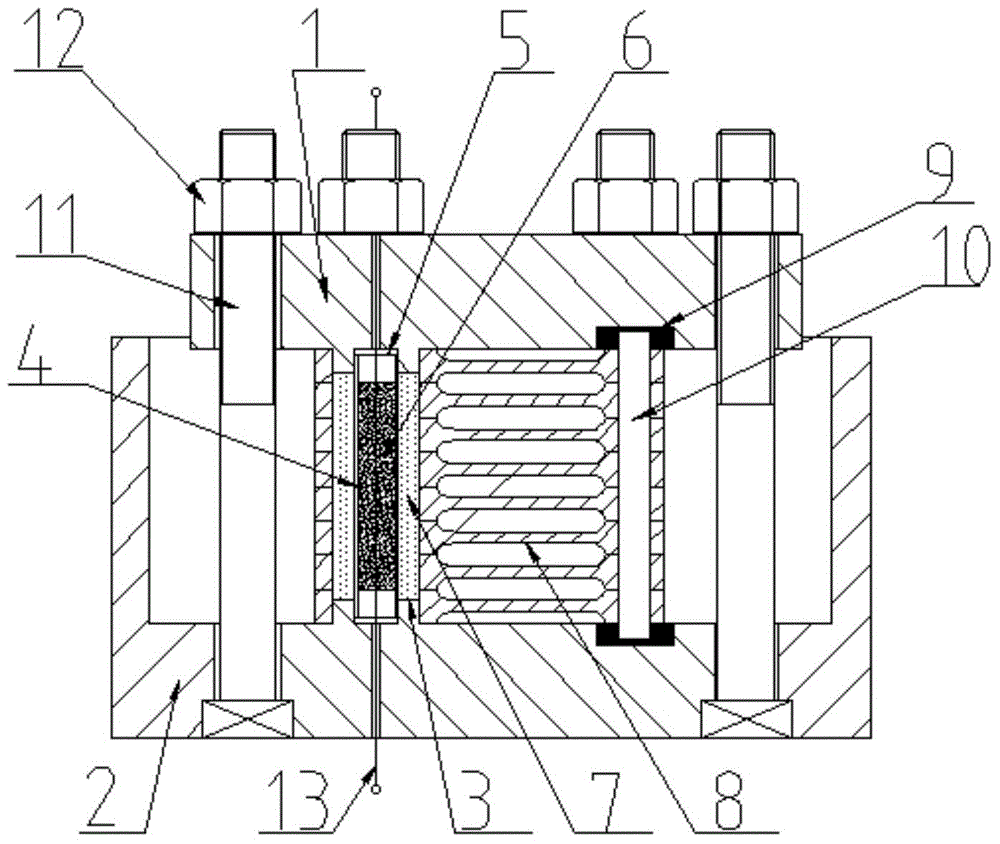

[0025] Step 2. Refer to figure 2 and image 3 , put more than two connecting rods 8 stacked into the bottom box 2, place the detonation body 4 and the expansion medium 7 in the big end hole of the connecting rod 8, press the cover plate 1 to compress, and pass the bolt 11 And nut 12 fastening;

[0026] Step 3: Trigger the high-voltage ball gap switch 18 to close through the laser 14, apply a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com