Photocurable 3D (three-dimensional) printing device and imaging system thereof

A 3D printing and imaging system technology, applied in optics, optical components, instruments, etc., can solve problems such as shortened life of liquid crystals, achieve the effects of narrowing light spots, avoiding distortion, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

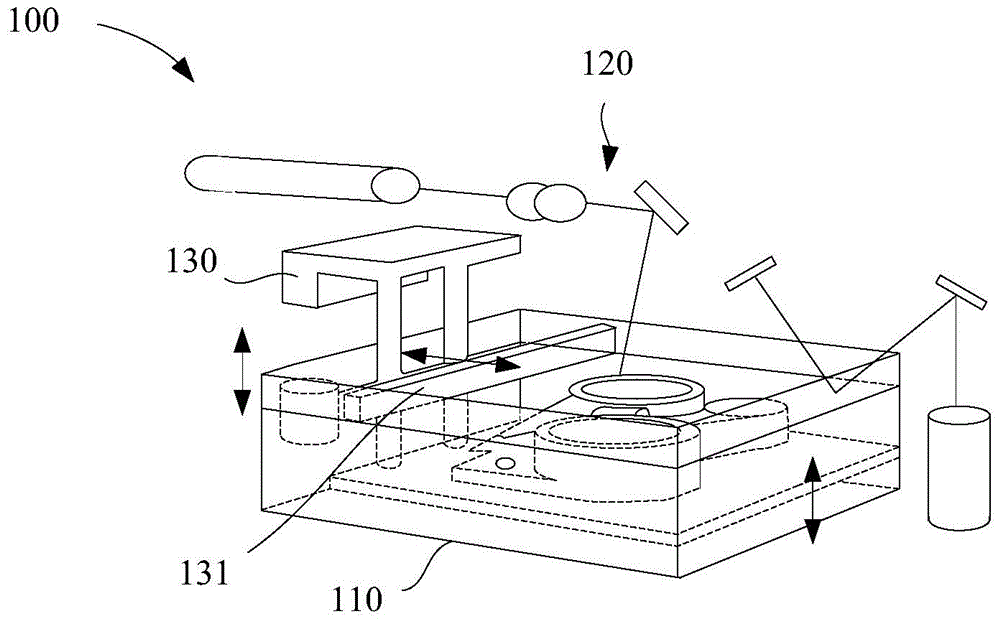

[0045] Embodiments of the present invention describe a light-curing 3D printing device and its imaging system. The imaging system uses a liquid crystal panel as an area array image source. Embodiments of the present invention omit the projection lens that causes distortion by redesigning the projection optical path. In order to avoid a significant shortening of the lifespan of the liquid crystal panel, the embodiment of the present invention can project a light beam image required for photocuring at an acceptable low light source power.

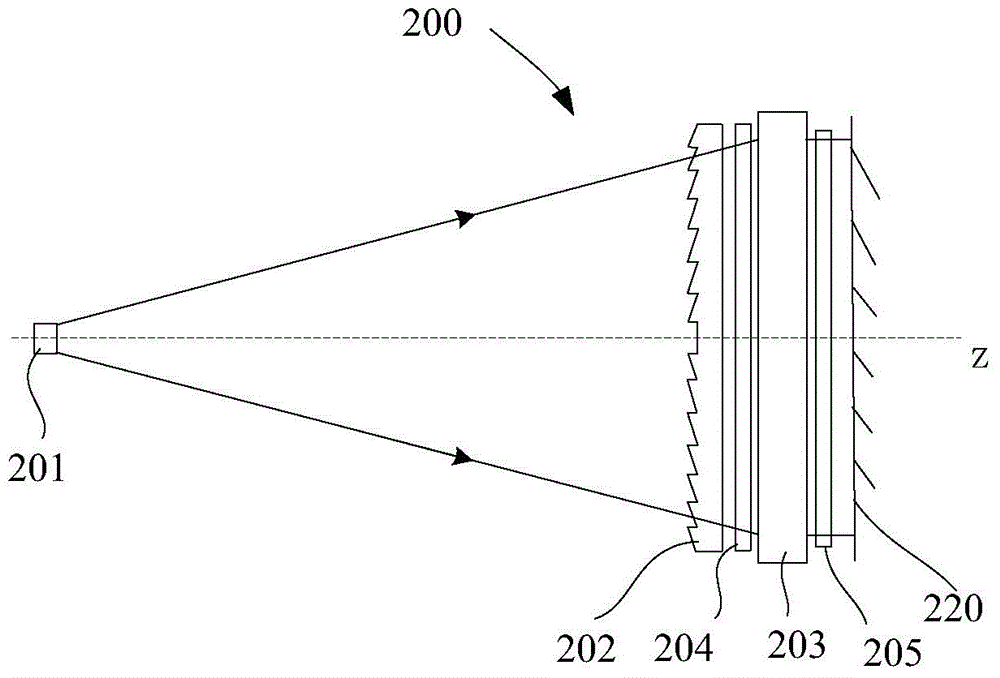

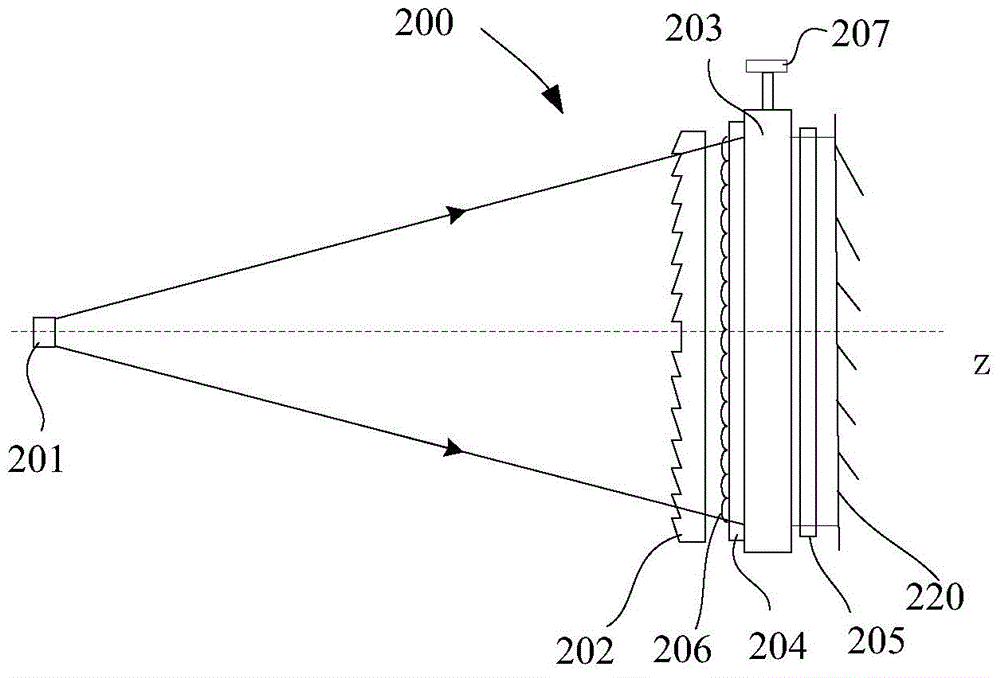

[0046] figure 2 An imaging system of a 3D printing device according to an embodiment of the present invention is shown. refer to figure 2 As shown, the imaging system of this embodiment includes a light source 201, a Fresnel lens 202, a liquid crystal panel 203, a first polarizing filter 204, a second polarizing filter 205 and a controller (not shown). For simplicity, optics that are not relevant to the present invention are not shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com