Method for increasing nitrogen content in vanadium-containing steel bar

A technology of nitrogen content and steel bars, applied in the field of steelmaking, can solve the problems of large fluctuations in nitrogen content, large amount of deoxidizer added, high production cost, etc., and achieve the effect of reducing the amount of alloy added, improving steel quality, and improving steel performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The nitrogen blowing flow at the bottom of the ladle during the converter tapping process is 0.5m 3 / min, the tapping temperature is 1680℃, the amount of vanadium slag added is 456kg, the oxygen activity of the molten steel is 28ppm, and the nitrogen content of the molten steel is 83.0ppm on the platform behind the furnace.

[0025] During the refining process of the LF furnace, according to the vanadium content of the molten steel in the early stage of refining, iron vanadium nitride is added to adjust the vanadium in the molten steel to the requirements of the steel grade. 3 / min, the heating time is 12min, the nitrogen blowing flow at the bottom of the ladle is 0.6m when the molten steel is stirred 3 / min, the refining time is 23min, and finally a molten steel with a nitrogen content of 179.2ppm is obtained, and the final molten steel composition is shown in Table 1.

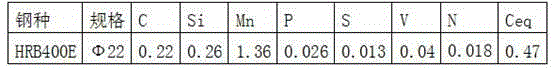

[0026] Table 1 Example 1 Composition of molten steel (wt %)

[0027]

Embodiment 2

[0029] The flow rate of nitrogen blowing at the bottom of the ladle in the converter tapping process is 0.6m 3 / min, the tapping temperature is 1649℃, the amount of vanadium slag added is 430kg, the oxygen activity of the liquid steel is 23.3ppm, and the nitrogen content of the liquid steel is 80.6ppm on the platform behind the furnace.

[0030] During the refining process of the LF furnace, according to the vanadium content of the molten steel in the early stage of refining, iron vanadium nitride is added to adjust the vanadium in the molten steel to the requirements of the steel grade. 3 / min, the heating time is 13min, the nitrogen blowing flow rate at the bottom of the ladle is 0.5m when the molten steel is stirred 3 / min, the refining time is 29min, and finally the molten steel with a nitrogen content of 158.1ppm is obtained, and the final molten steel composition is shown in Table 2.

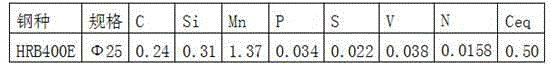

[0031] Table 2 Example 2 Composition of molten steel (wt %)

[0032]

Embodiment 3

[0034] The nitrogen blowing flow rate at the bottom of the ladle during the converter tapping process is 0.65m 3 / min, aluminum, manganese, calcium, iron is added for deoxidation, the tapping temperature is 1679°C, the amount of vanadium slag added is 414kg, the oxygen activity of liquid steel after deoxidation is 28ppm, and the nitrogen content of liquid steel is 90.0ppm on the platform behind the furnace.

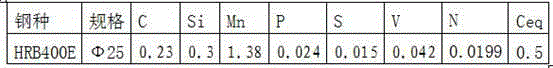

[0035] During the refining process of the LF furnace, according to the vanadium content of the molten steel in the early stage of refining, iron vanadium nitride is added to adjust the vanadium in the molten steel to the steel grade requirements. When the molten steel is heated, the nitrogen flow rate at the bottom of the ladle is 0.21 m 3 / min, the heating time is 9min, the nitrogen blowing flow at the bottom of the ladle is 0.6m when the molten steel is stirred 3 / min, the refining time is 25min, and finally molten steel with a nitrogen content of 198.75ppm is obtained. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com