Ecological slope protecting method

An ecological slope protection and slope surface technology, applied in the field of environmental management, can solve the problems of affecting plant growth, loss of fertilizer efficiency, and reducing water purification effect, etc., to achieve the effect of improving continuous fertilizer efficiency, maintaining stability, and enhancing water purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

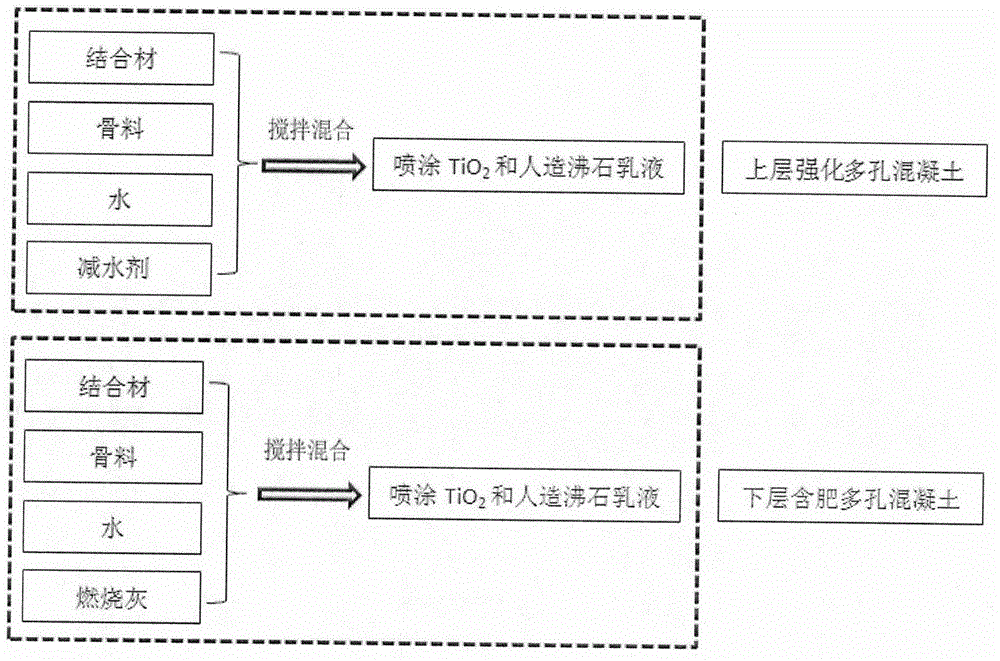

[0032] Such as figure 1 Shown, a kind of ecological slope protection method of the present invention comprises the following steps:

[0033] a) Level the slope to be treated.

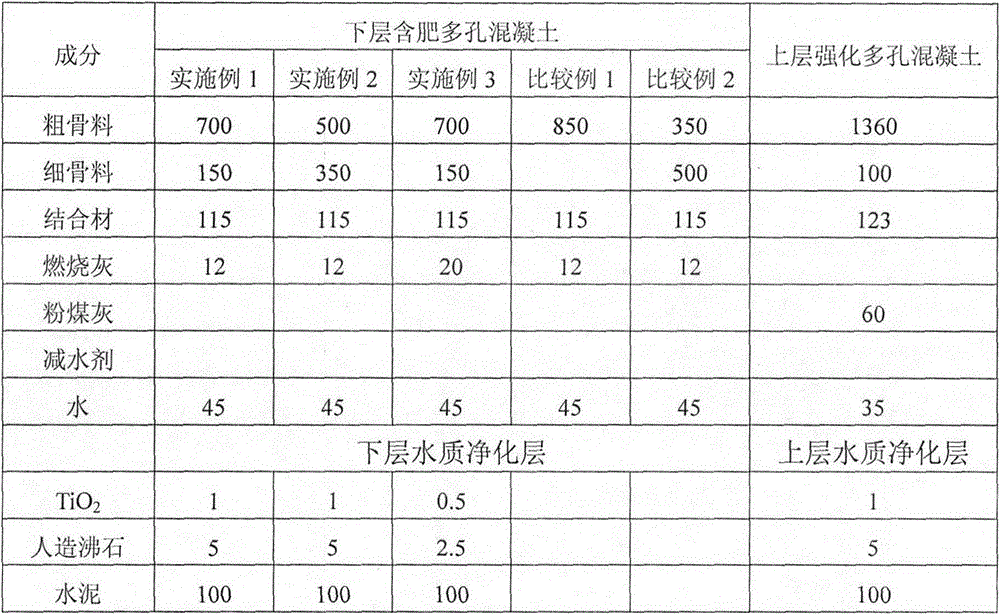

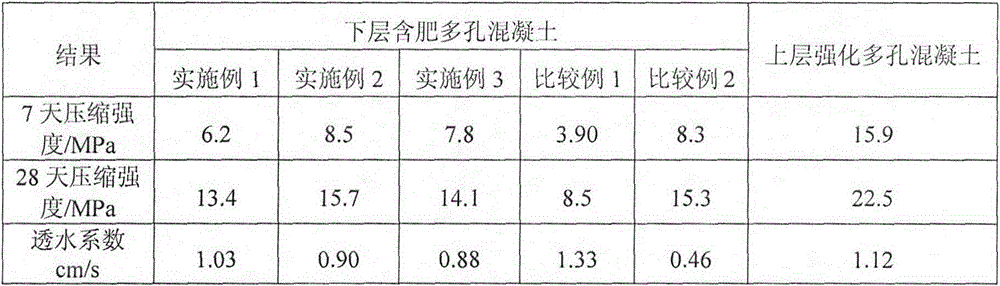

[0034] b) Lay the lower layer of fertilized porous concrete: Stir and mix the aggregate, binding material, combustion ash and water, spread it on the leveled slope to be treated, and compact it with the plate. Aggregate includes coarse aggregate (aggregate with a particle size of 1-3cm) and fine aggregate (aggregate with a particle size of 0.1-1cm). It is dried crushed stone sludge with a particle size of about 0.5cm; the binder is ordinary Portland cement 525R (China Cement Plant of Nanjing Changjiang Cement (Group) Company, Jiangsu Province); the combustion ash is bark combustion ash, and the chemical composition is shown in the table 1; The water is tap water. The parts by weight of aggregate, binding material, burning ash and water in the fertile porous concrete of the lower layer are: 700 parts ...

Embodiment 2

[0045] A kind of ecological slope protection method of the present invention adopts the steps method identical with embodiment 1, and reset embodiment 1 step b) the weight part of aggregate, binding material, burning ash and water in the lower layer of fertile porous concrete as this implementation For example, specifically: 500 parts of coarse aggregate, 350 parts of fine aggregate, 115 parts of binder, 12 parts of combustion ash, and 45 parts of water.

Embodiment 3

[0047] A kind of ecological slope protection method of the present invention adopts the steps method identical with embodiment 1, and resets embodiment 1 step b) the weight part of aggregate, bonding material, burning ash and water in the fertile porous concrete of lower floor, specifically as : 700 parts of coarse aggregate, 150 parts of fine aggregate, 115 parts of binding material, 20 parts of combustion ash, 45 parts of water; reset embodiment 1 step c) TiO in the lower floor water purification layer 2 Parts by weight of photocatalyst, artificial zeolite and cement, specifically: TiO 2 1 part of photocatalyst, 5 parts of artificial zeolite, and 100 parts of cement are used as this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com