Multipoint fastening and reinforcing method for concrete silo structure

A technology for concrete and silos, applied in building construction, building maintenance, construction, etc., can solve the problems of poor overall bearing capacity and rigidity reinforcement effect of silos, poor co-working ability of old and new structures, poor working ability of old and new structures, etc. Achieve the effect of good collaborative work performance, strong engineering application value, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

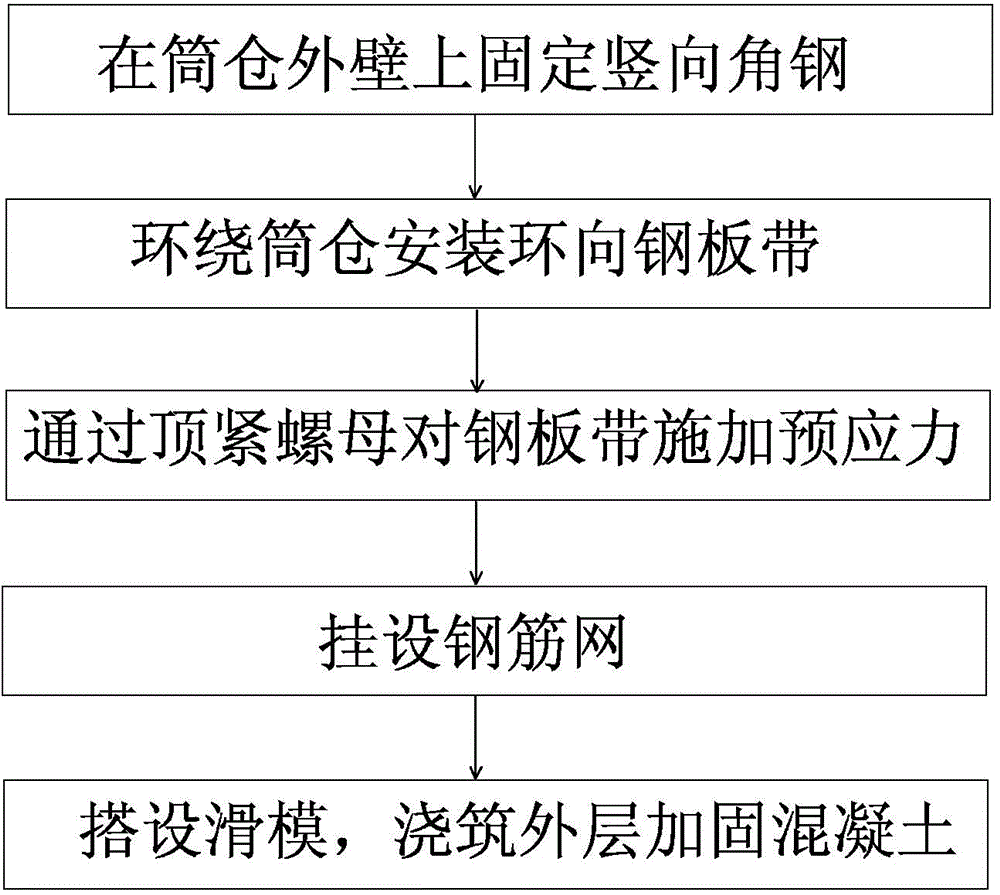

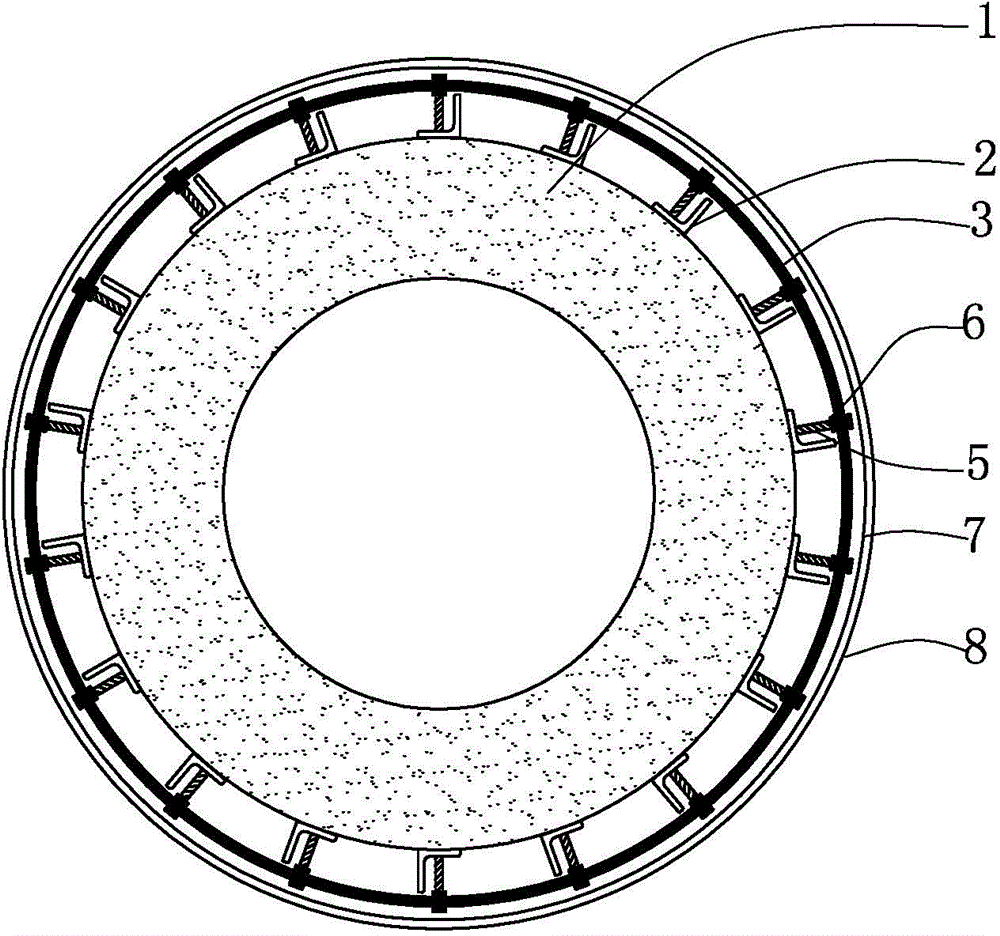

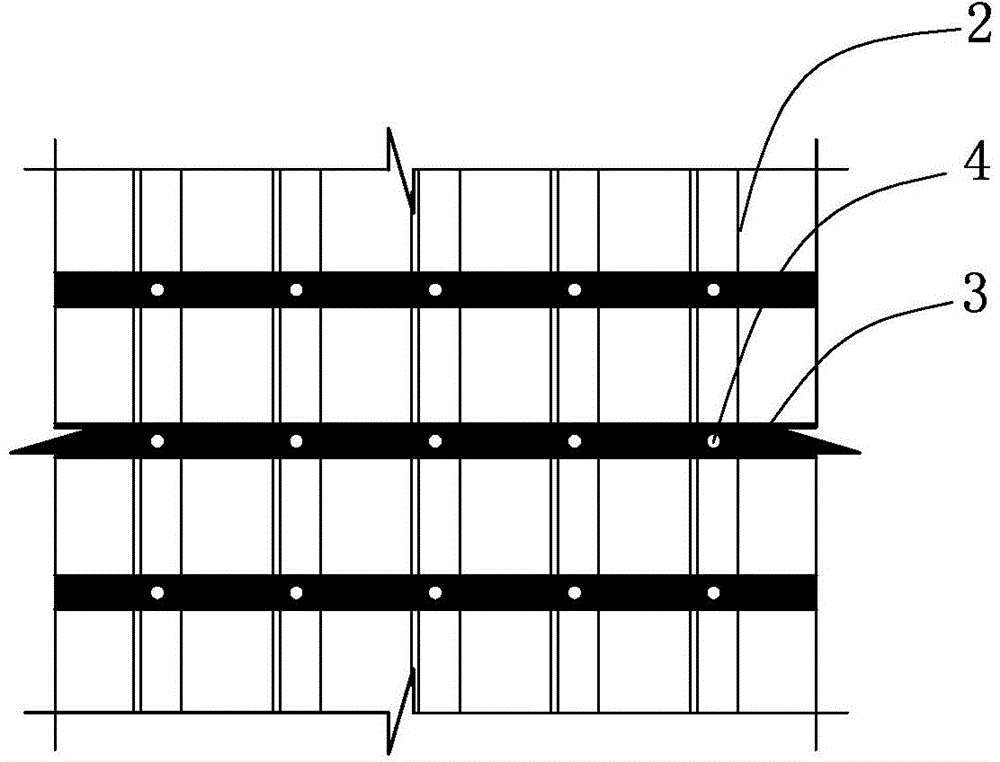

[0029] The multi-point fastening body reinforcement method for concrete silos of the present invention is a reinforcement method for the existing silo structure. Through the evaluation of the bearing capacity of the existing silo structure, this method can be used when the bearing capacity cannot meet the load requirements of the structure. Strengthen the silo structure. The present invention adopts the vertical angle steel backing plate and the hoop prestressed steel strip, and the stress of the hoop prestressed steel strip is the main force, and the vertical angle steel backing plate is supplemented; The original silo wall is combined, and the hoop prestressed steel belt applies the prestress required to increase the bearing capacity through high-strength bolts. After the multi-point fastening system is completed, the silo is hung with steel mesh, concrete is poured and maintained, and the multi-point fastening is completed. reinforcement. The reinforcing method flow proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com