Air intake and exhaust device and method for ocean robot

A technology of air intake and exhaust and robot, applied in the direction of valve device, machine/engine, mechanical equipment, etc., can solve the problems of small exhaust back pressure, affecting power performance, etc., and achieve the effect of small back pressure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

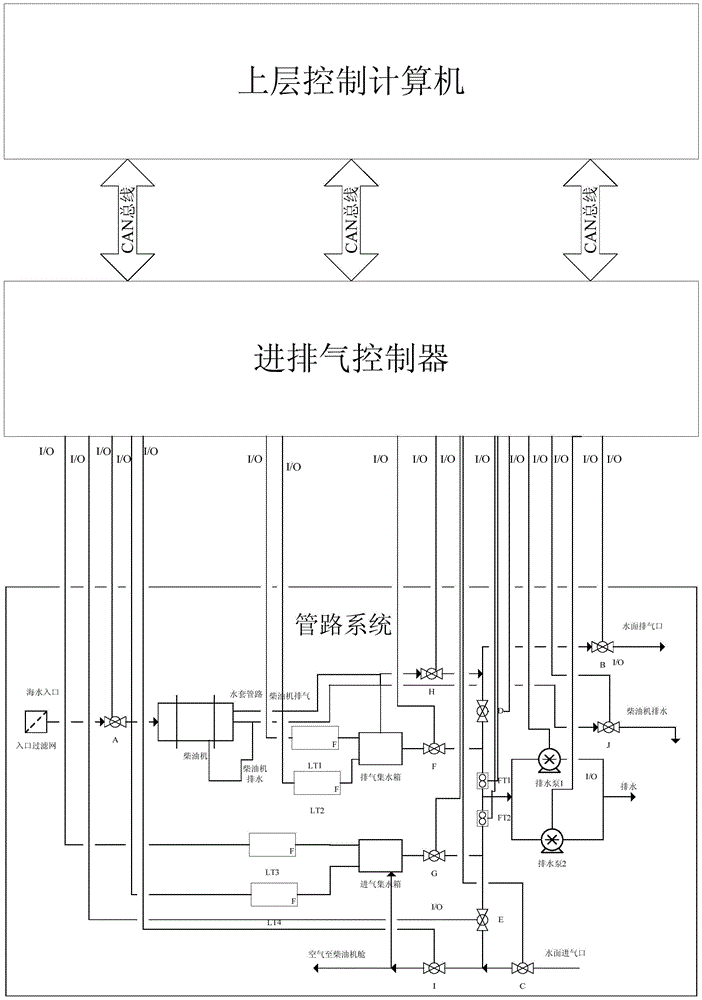

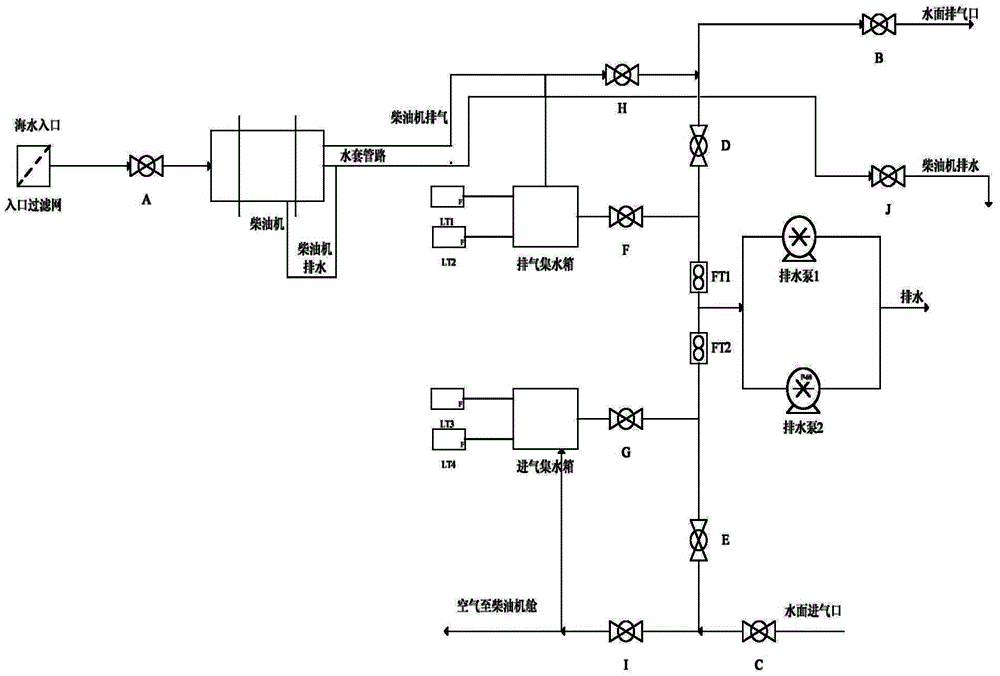

[0042] 1. As attached figure 1 As shown, the present invention is a device designed for the air intake and exhaust emission of marine robots when the diesel engine is powered, and is composed of an air intake part and an exhaust part. Air controller, intake and exhaust controller drive hydraulic valves, electric ball valves, and drainage pumps according to control commands, and at the same time, the intake and exhaust controllers feed back the working status to the upper control computer through the CAN bus to realize automatic control. figure 1 The middle pipeline system is connected to the intake and exhaust controller, and the "open circuit" in the figure does not mean that it is not connected, but means that the connection between the pipeline system and the intake and exhaust controller does not affect the internal connection relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com