Drawer cabinet type electric warmer made of open-cell foamed aluminum materials

An open-cell aluminum foam, electric heater technology, applied in the application, household heating, heating methods and other directions, can solve the problems of high cost, complex structure, low thermal efficiency, etc. The effect of high electrothermal conversion rate

Inactive Publication Date: 2015-06-03

HUNAN UNIV

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When working, the electric heating element transfers heat to the heat-conducting layer on the heat-dissipating element, and then the heat-dissipating layer dissipates the heat to the inner cavity of the shell, and finally, the shell made of heat-conducting material dissipates the heat for people to use for heating , but there are many heat transfer layers, low thermal efficiency, high energy consumption and other defects

In order to eliminate the above defects and improve thermal efficiency, the 201220131365.4 patent discloses a PTC electric heating heater, which consists of PTC electric heating rod, heat sink, connecting rod, left end shell, right end shell, controller, casters, and splint 8. It is characterized in that it adopts PTC semiconductor As a heating element rod, inserted into the heat sink of aluminum alloy die-casting round tube, it has the beneficial effects of fast heating, fast heat dissipation, no overheating runaway, no medium oil conduction, no leakage pollution, light weight, etc., but the structure is more complicated , only radiation heat transfer, no convective heat transfer, which affects its use effect, and the form is relatively simple

[0003] There are a variety of vertical electric heaters introduced and developed in the market, but they all focus on electric heating parts, such as electric heating film, carbon fiber electric heating parts, etc., which have good heating effect and light weight, but almost all of them are made of metal materials with good thermal conductivity Making the shell not only increases the weight, but also costs a lot. Almost all vertical heaters are connected by welding, riveting, bonding, bolts and nuts, etc., combining materials with different functions into a whole that cannot be disassembled. cause great inconvenience

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

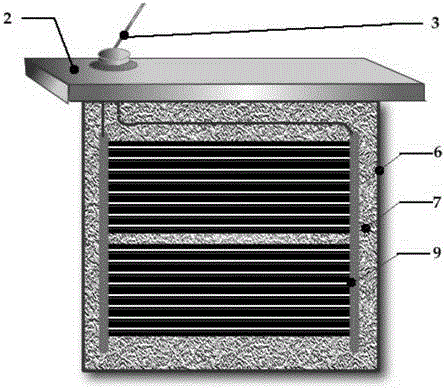

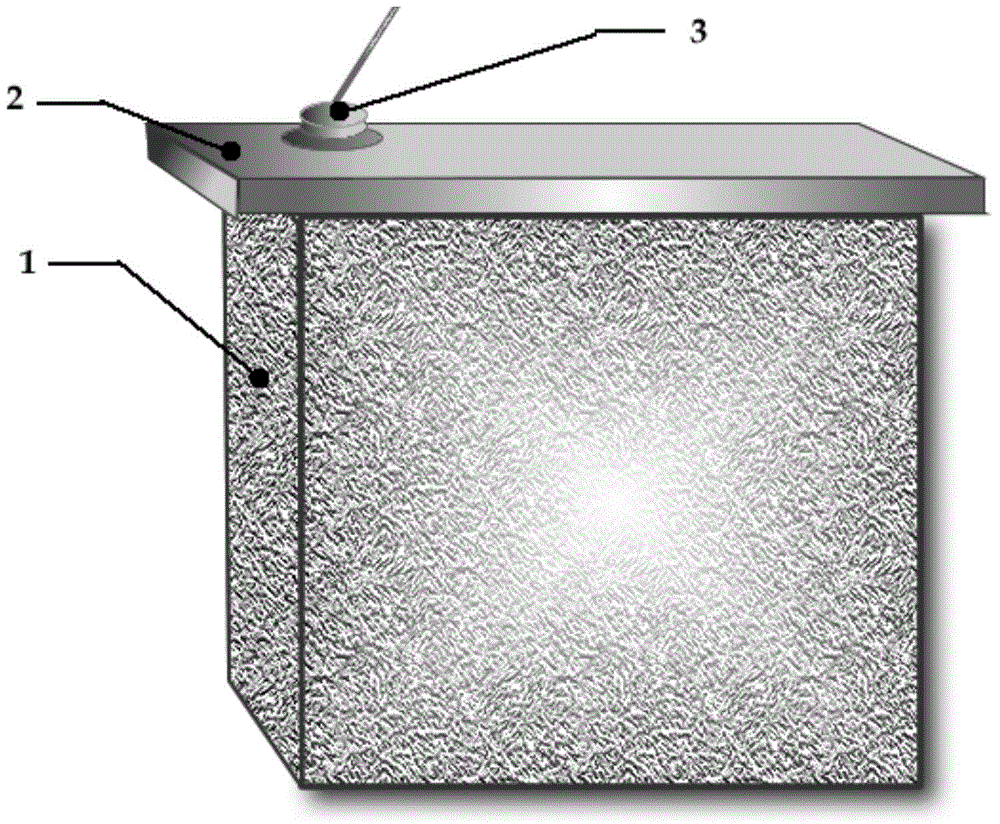

[0027] figure 1 1 is the cabinet body, 2 is the drawer cover, 3 is the power cord, and the base is omitted;

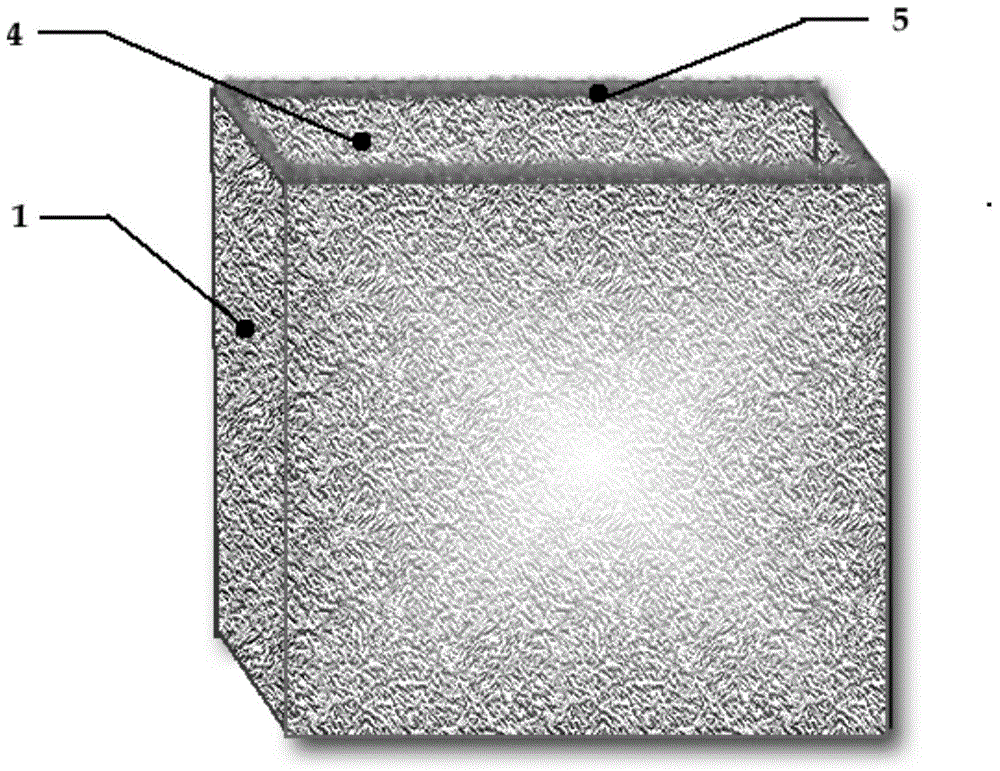

[0028] figure 2 4 is the inner chamber of the cabinet, and 5 is the cavity wall of the cabinet;,

[0029] image 3 Among them, 6 is the side board of the drawer, 7 is the bottom plate of the drawer, and 8 is the circular heating element;

[0030] Figure 4 9 in it is a flat heating element.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of electric warmers, in particular to a drawer cabinet type electric warmer made of open-cell foamed aluminum materials. The shortcomings of the existing vertical electric warmer are overcome, design fundamentals of heating power, bearing, light weight, heat transfer, heat conduction, heat dissipation, electromagnetic shielding, safety, environmental protection, low cost and decoration are integrated, and the drawer cabinet type electric warmer made of the open-cell foamed aluminum materials is simple in structure and convenient to assemble and disassemble, and is light, energy-saving, attractive, elegant, safe and environment-friendly. A drawer has functions of heating element fixing, wiring and power socket and heating piece changing and repairing; and a cabinet body has functions of bearing, heat transferring, heat conduction, heat dissipation, electromagnetic shielding and surface decoration.

Description

[0001] The invention relates to the technical field of electric heaters, in particular to a drawer-type electric heater made of open-cell foamed aluminum, referred to as the drawer-type electric heater. Background technique [0002] The structure of the existing electric heater generally includes a shell, an electric heating element and a heat dissipation element. The heat dissipation element is installed in the inner cavity of the casing. The heat dissipation element is provided with a heat conducting layer and a heat dissipation layer. When working, the electric heating element transfers heat to the heat-conducting layer on the heat-dissipating element, and then the heat-dissipating layer dissipates the heat to the inner cavity of the shell, and finally, the shell made of heat-conducting material dissipates the heat for people to use for heating , but there are many heat transfer layers, low thermal efficiency, high energy consumption and other defects. In order to eliminate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F24D13/02F24D19/00

Inventor 汪原汪国杰

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com