High-strength climbing type double-splint thin shell buckle lining structure

A double splint and furnace lining technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as unreasonable furnace lining structure, and achieve the effect of increasing air tightness and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

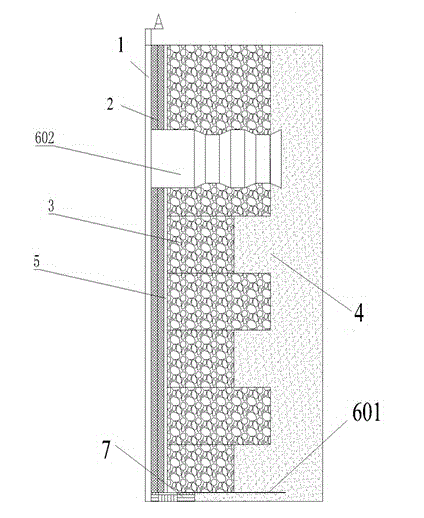

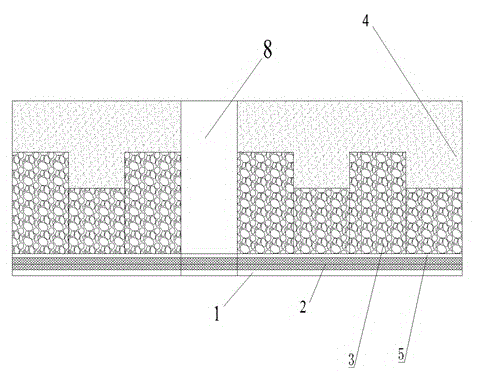

[0035] As shown in the figure, a high-strength climbing double-plywood thin-shell buckle lining structure divides the lining into several partitions, and the edge of each lining partition is provided with a metal separation ring 7 or refractory concrete fixed on the steel shell 1. Isolation beam 8, metal separation support ring 7 or refractory concrete separation beam 8 unloads the weight of the partitioned furnace lining on the steel shell 1; the structure of each furnace lining partition is sequentially composed of flexible isolation layer 2 and light insulation layer from outside to inside 3 and the castable working layer 4, wherein a high-strength coating layer 5 is provided on both sides of the flexible isolation layer 2, and the flexible isolation layer 2 is connected to the steel shell 1 and the light insulation layer 3 respectively through the high-strength coating layer 5 on both sides Fixing, the two opposing surfaces of the light heat insulating layer 3 and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com