Method for detecting chlorine content in zirconium oxide

A detection method and technology for chlorine content, applied in the field of zirconia, to achieve the effects of accurate numerical value, easy operation and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

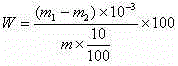

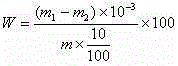

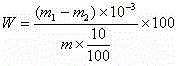

Image

Examples

Embodiment

[0023] The method for detecting chlorine content in zirconia according to the present invention adopts a sample to form a curdled silver chloride suspension with silver nitrate in a slightly acidic solution, and carries out turbidity detection, and is suitable for zirconia calcined blocks, Zirconia granulated powder, zirconia airflow powder and other powder materials.

[0024] 1. Reagents:

[0025] Nitric acid solution (C(HNO3)=1mol / L: Measure 62.5ml of nitric acid (specific gravity is 1.42g / cm 3 ) in a 1L volumetric flask, add water to the mark and shake well.

[0026] Silver nitrate solution (0.1%): Dissolve 0.1g of silver nitrate in a 100ml volumetric flask, add water to the mark and shake well.

[0027] 2. Chlorine standard solution (0.1mg / ml):

[0028] Accurately weigh 0.1649g of standard sodium chloride that has been dried at 270~300°C in a beaker, dissolve it in water, transfer it to a 1L volumetric flask, dilute to the marked line, mix well, and store in a plastic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com