Temperature control system for ageing cabinet for multiple direct-current power supplies

A technology of temperature control system and DC power supply, applied in the field of power supply, which can solve the problems of poor adaptability of products of various capacity levels, difficult cost-effective energy feedback, energy dispersion, etc., and achieve good temperature control effect, high working reliability and stability , uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

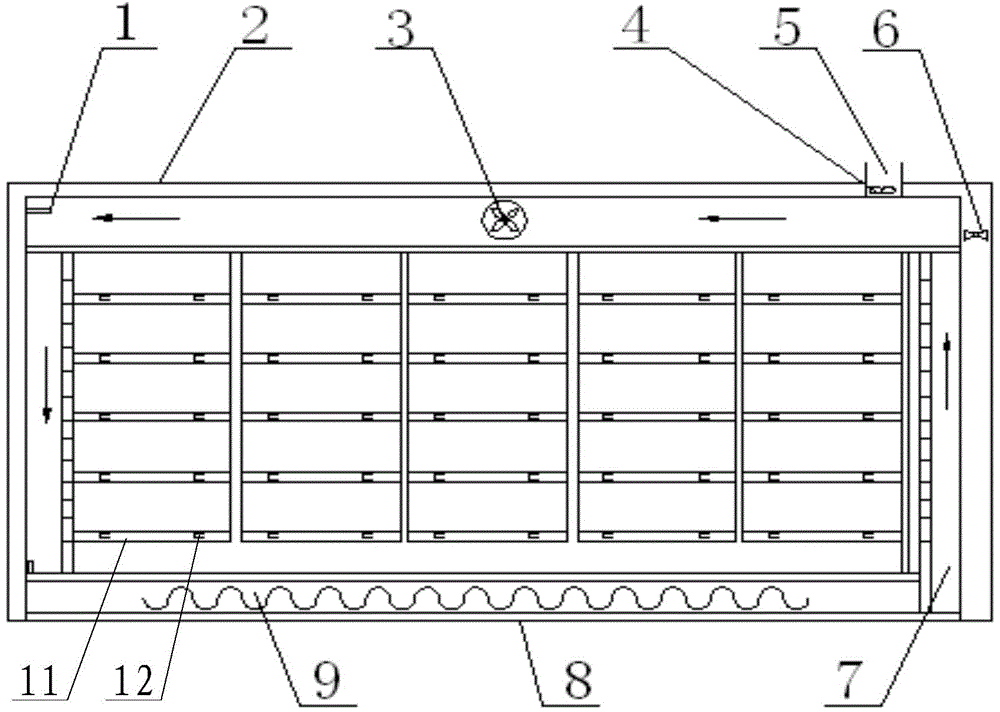

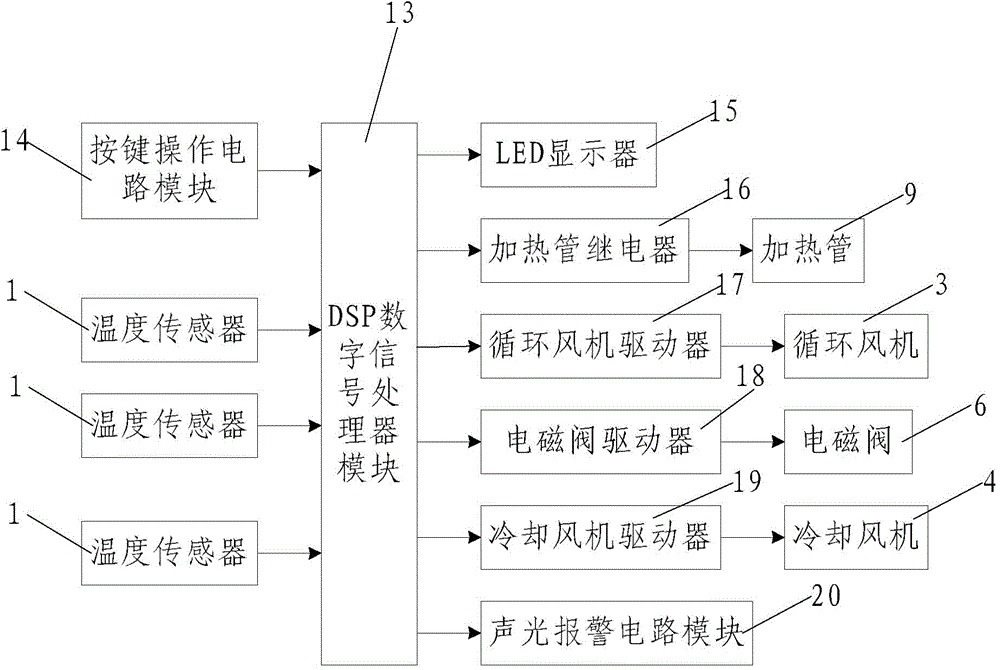

[0026] Such as figure 1 and figure 2 As shown, in the temperature control system for multiple DC power aging cabinets described in the present invention, the multiple DC power aging cabinets include an aging cabinet body 2 with a hollow base 8, and the base 8 is provided with a The heating pipe 9 for heating the aging cabinet body 2, the interior of the aging cabinet body 2 is provided with a multi-layer aging rack 11, and a plurality of aging racks 11 for plugging in multiple DC power supplies are provided on each layer. A power socket 12, a plurality of the power sockets 12 are first connected in series to form a plurality of series branches, and then a plurality of series branches are connected in parallel. The side and top of the aging frame 11 are provided with interconnected circulating air ducts 7, which are located in the A circulating fan 3 is arranged in the circulating air duct 7 on the top of the aging frame 11, and a cooling air duct 5 is arranged on the periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com