Novel pressure tube type IGBT water cooling plate

A technology of water-cooled plates and pressure tubes, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of large flow channel pressure difference and uneven distribution of flow channels, achieve small inlet and outlet pressure differences, improve heat dissipation performance, and process convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

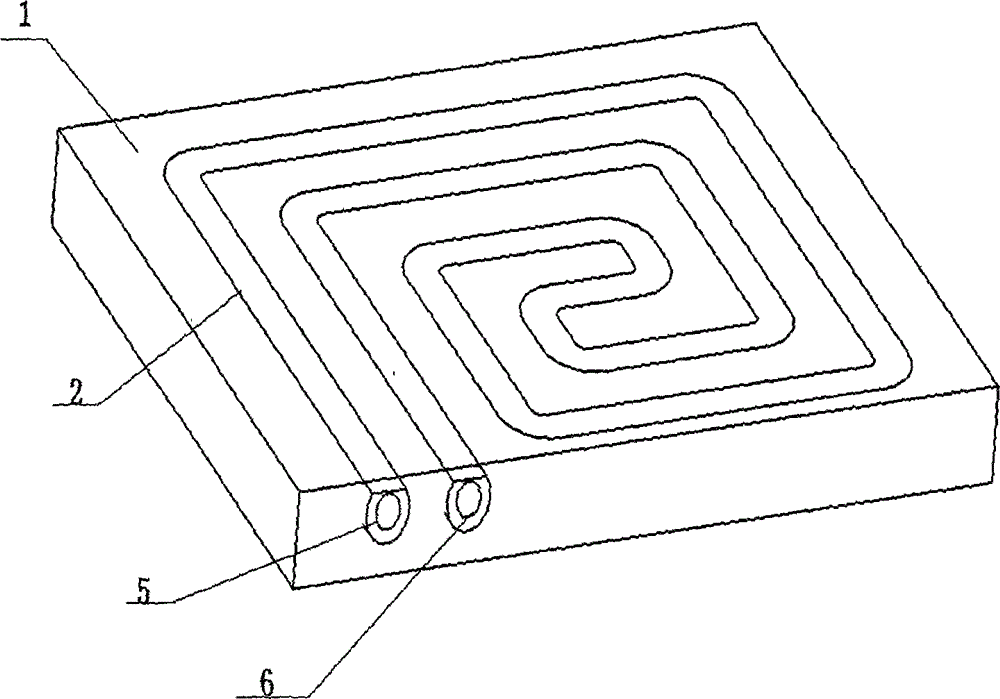

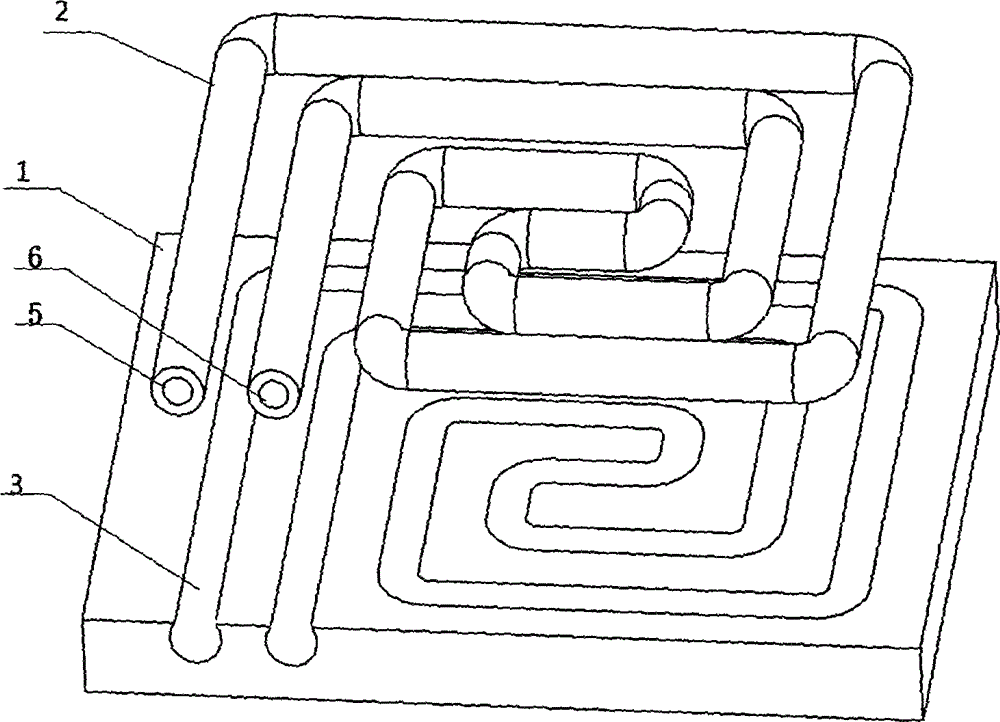

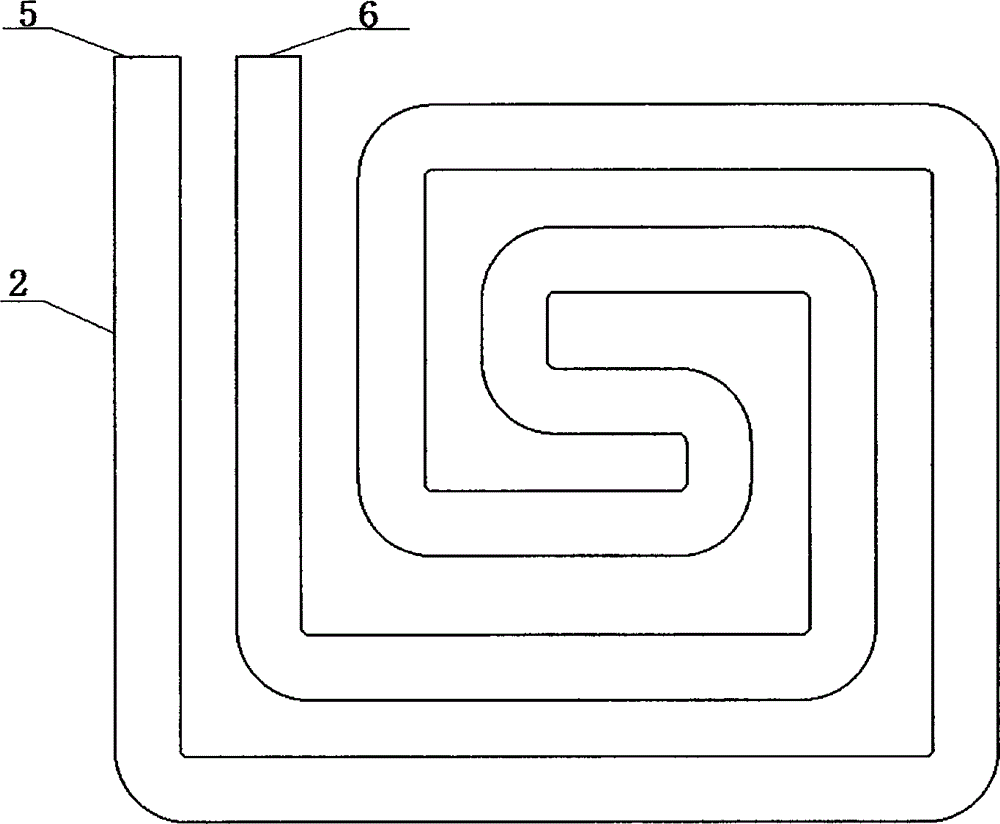

[0026] Such as figure 1 and figure 2 As shown, a new pressure tube type IGBT water-cooled plate includes a water-cooled plate substrate 1 and an improved S-shaped flow channel 2; the material of the water-cooled plate substrate 1 is made of aluminum structure, and the water-cooled plate substrate 1 is machined with S Shaped runner cavity 3, the improved S-shaped runner 2 is embedded and pressed in the groove 3 of the water-cooled plate substrate 1; and the improved S-shaped runner 2 is flattened through CNC surface processing, and the improved S-shaped runner 2 is guaranteed. The exposed plane of the S-shaped runner 2 copper pipe is on the same plane as the water-cooled plate substrate 1 .

[0027] In particular, a small amount of high thermal conductivity epoxy resin is filled between the improved S-shaped flow channel 2 and the cavity 3 .

[0028] In particular, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com