Integrated multipath dielectric phase shifter

A phase shifter and medium technology, applied in circuits, waveguide-type devices, electrical components, etc., can solve the difficulty and poor consistency of the assembly of the base station electrical adjustment antenna, the disadvantage of the overall layout of the antenna feed network, and the zero phase shifter. Too many components, etc., to achieve the effect of convenient feeding network design, simple manufacturing and assembly, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

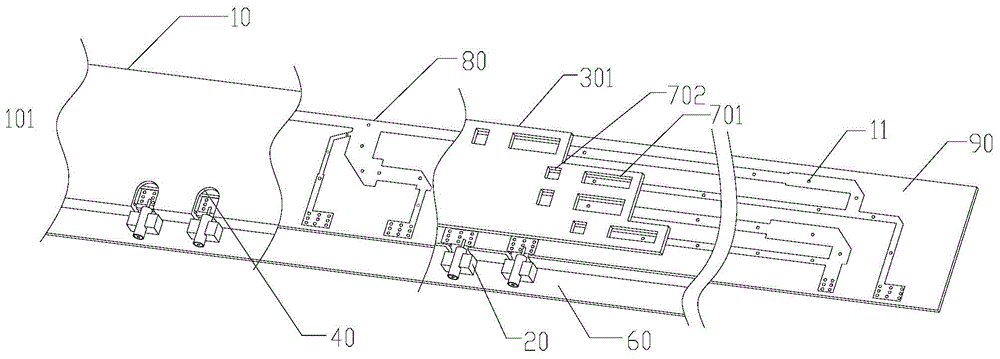

[0034] see figure 1 The multi-channel integrated dielectric phase shifter 101 provided in Embodiment 1 of the present invention includes a cavity 10, a first dielectric board 301, a second dielectric board 302 and a PCB board 90:

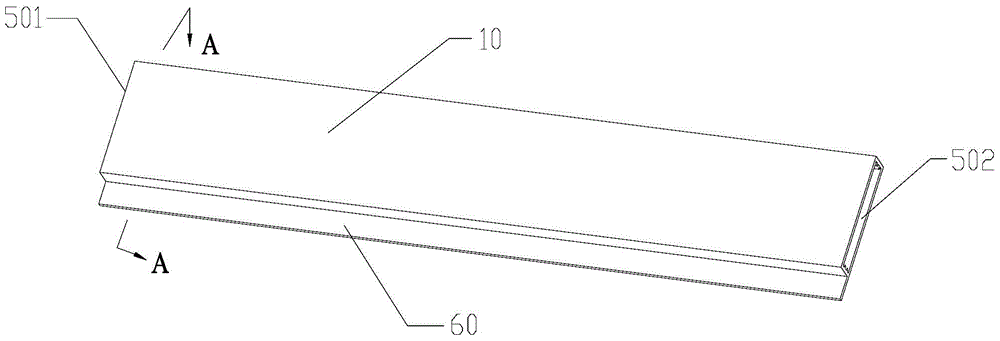

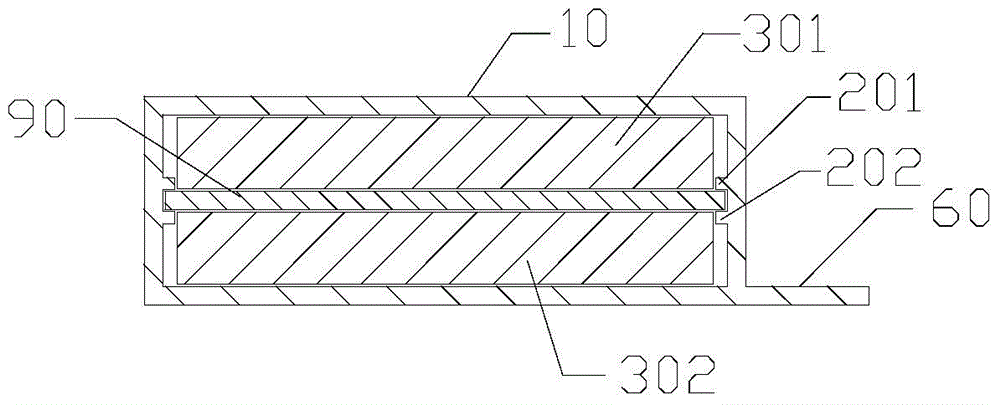

[0035] The cavity 10 is integrally formed in the shape of a cuboid, with openings 501 and 502 at both ends, and guide rail grooves on the side walls. The PCB board 90 is fixed in the cavity 10 through the guide rail grooves. Let the length, width and height of the cavity 10 be A, B, and C respectively, A is greater than B, and the two ends with a length of B have openings 501 and 502 respectively, so that when using the multi-channel integrated dielectric phase shifter provided by the present invention, The first dielectric plate 301 and the second dielectric plate 302 are connected to the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com