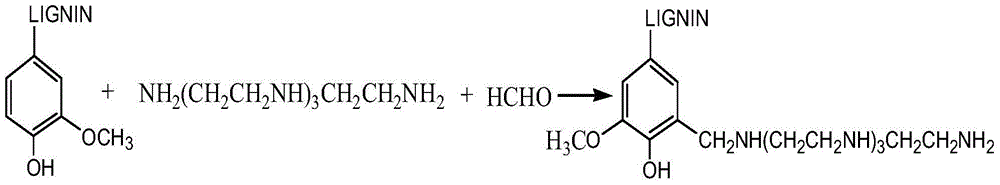

Tetraethylenepentamine/ formaldehyde modified lignin-amine asphalt emulsifier synthetic process

A technology of tetraethylenepentamine and lignin, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of thin covering film, reduce interfacial tension, high interfacial activity and oil phase compatibility, and improve interfacial Effect of activity and oil compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Take a certain amount of emulsifier in a beaker, add 200ml of water, heat to 50-60°C, stir with a glass rod to dissolve it, and adjust the pH to 2-3 with industrial hydrochloric acid. Then weigh 300g of No. 150 road petroleum asphalt, and heat it to 110°C to melt it. Start the colloid mill (preheat it with 60°C hot water before starting), inject the emulsifier aqueous solution into the colloid mill, then slowly pour the asphalt into the colloid mill for emulsification, and put the emulsion into the colloid mill for about one minute. Mineral water bottle, close the colloid mill.

[0023] Weigh 100g of stone, take a certain amount of water and additives, add it to the iron bowl, mix evenly, then weigh a certain amount of emulsified asphalt, pour it into the iron bowl, stir quickly and fully, and start timing, and the record can be mixed time and molding time.

[0024] Emulsification conditions: No. 100 road petroleum asphalt, pH=2~3, emulsifier dosage is 2~5%...

Embodiment 2

[0030] Example 2: Weigh a certain amount of emulsifier in a beaker, add 200ml of water, heat to 50-60°C, stir with a glass rod to dissolve it, and adjust the pH to 2-3 with industrial hydrochloric acid. Then weigh 300AH-90 asphalt and heat it to 120°C to melt it. Start the colloid mill (preheat it with 60°C hot water before starting), inject the emulsifier aqueous solution into the colloid mill, then slowly pour the asphalt into the colloid mill for emulsification, and put the emulsion into the colloid mill for about one minute. Mineral water bottle, close the colloid mill.

[0031] Weigh 100g of stone, take a certain amount of water and additives, add it to the iron bowl, mix evenly, then weigh a certain amount of emulsified asphalt, pour it into the iron bowl, stir quickly and fully, and start timing, and the record can be mixed time and molding time.

[0032] Emulsification conditions: 300AH-90 asphalt, pH=2, emulsifier dosage is 2-5%.

[0033] Emulsification effect: com...

Embodiment 3

[0038] Example 3: Take a certain amount of emulsifier in a beaker, add 200ml of water, heat to 50-60°C, stir with a glass rod to dissolve it, and adjust the pH to 2-3 with industrial hydrochloric acid. Then weigh 300g of Road Petroleum Asphalt No. 140, and heat it to 100°C to melt it. Start the colloid mill (preheat it with 60°C hot water before starting), inject the emulsifier aqueous solution into the colloid mill, then slowly pour the asphalt into the colloid mill for emulsification, and put the emulsion into the colloid mill for about one minute. Mineral water bottle, close the colloid mill.

[0039] Weigh 100g of stone, take a certain amount of water and additives, add it to the iron bowl, mix evenly, then weigh a certain amount of emulsified asphalt, pour it into the iron bowl, stir quickly and fully, and start timing, and the record can be mixed time and molding time.

[0040] Emulsification conditions: No. 180 road petroleum asphalt, pH=2, emulsifier dosage is 2-5%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com