A storage-stable, aging-resistant composite SBS particle asphalt modifier and preparation method thereof

An asphalt modifier and anti-aging technology, applied in building components, building insulation materials, buildings, etc., can solve the problems that rubber powder cannot be highly activated, increase the viscosity of modified asphalt system, weaken the modification effect, etc. Excellent aging performance, excellent high temperature storage stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

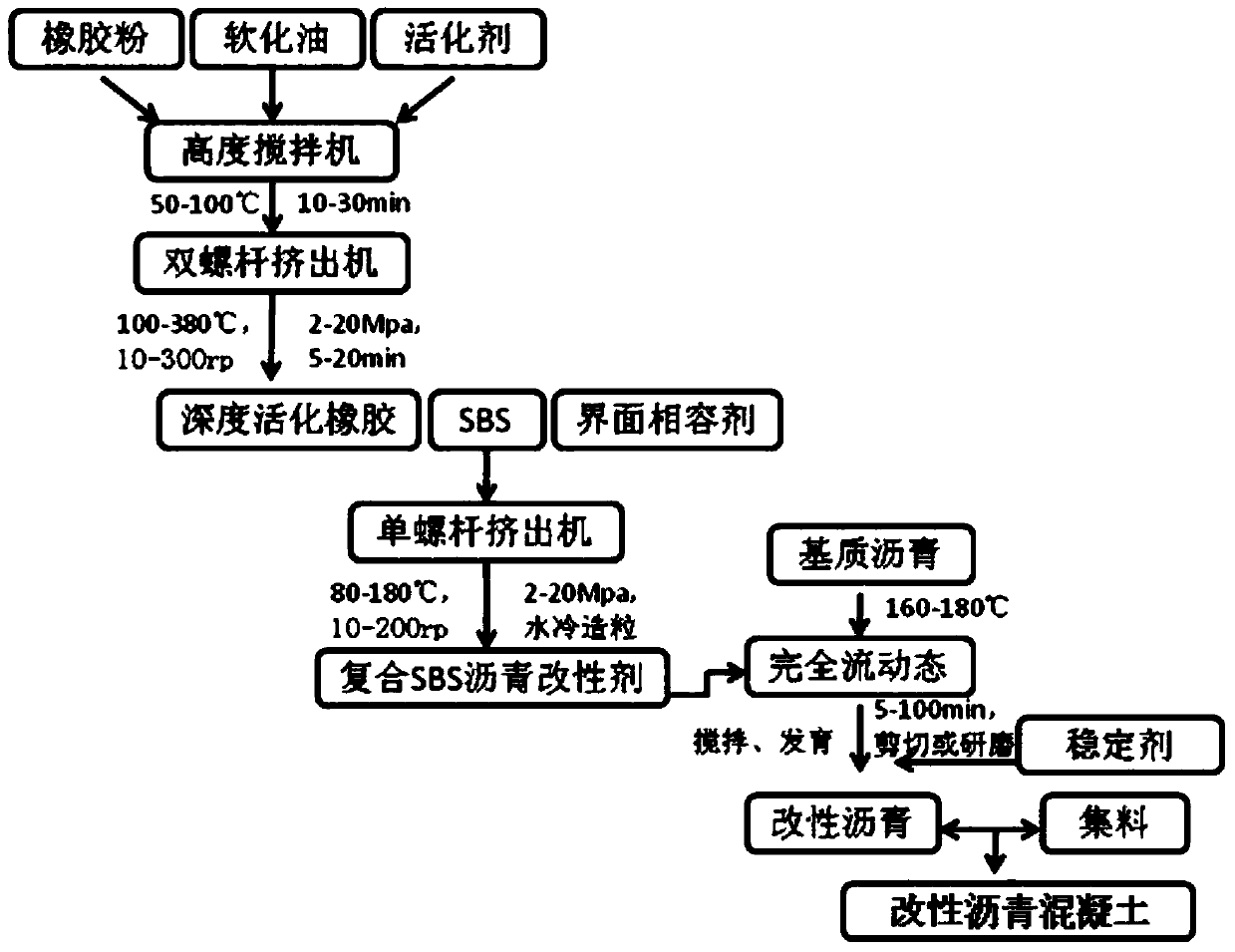

Method used

Image

Examples

Embodiment 1

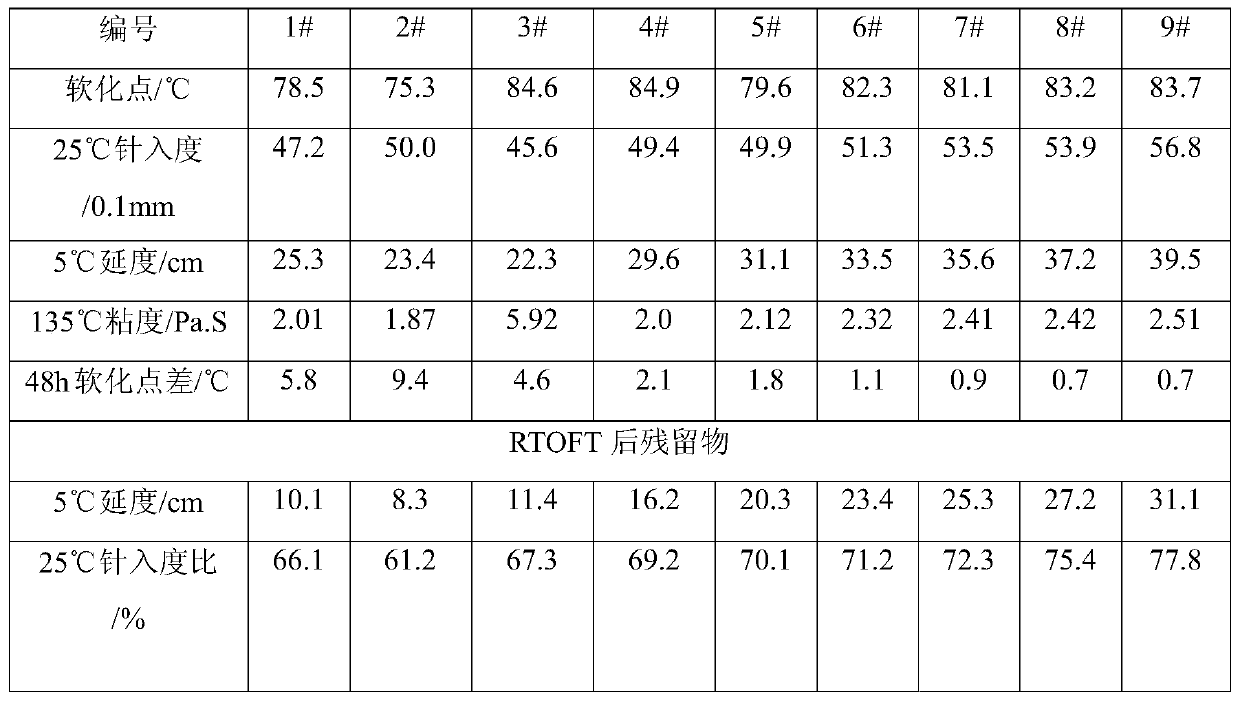

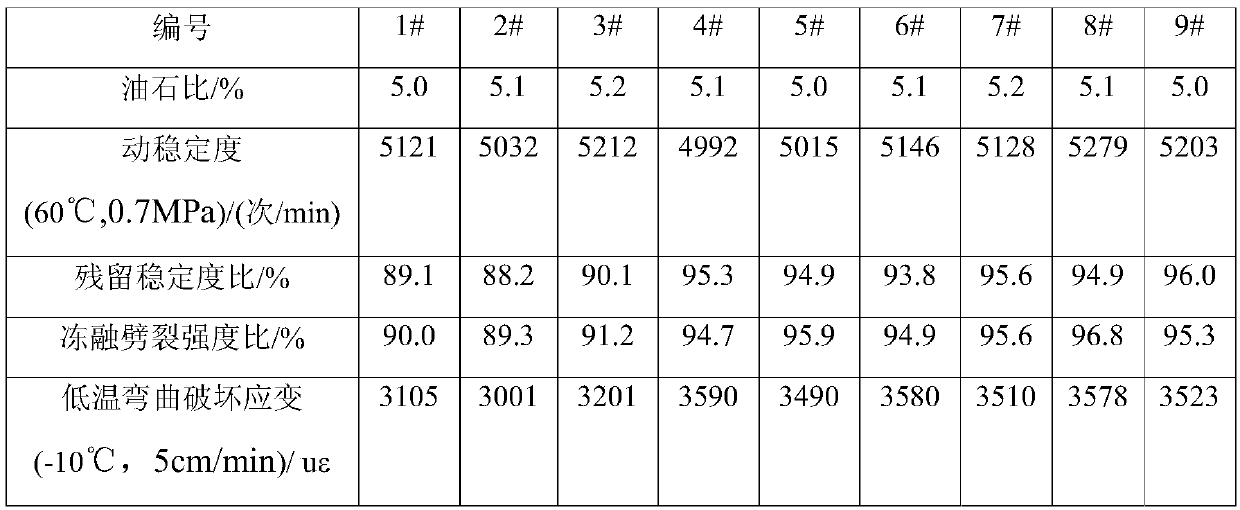

[0036]Pretreat rubber powder, softening oil, and activator in a high-speed mixer at 70°C for 15 minutes according to the weight ratio of 100:5:2, and add them to the first screw extruder by metering, and control the temperature of different sections of the twin-screw at 100-380°C . Among them, the first section: 150-200°C, the second section: 250-300°C; the third section: 300-350°C; the fourth section: 300-350°C; the fifth section: 150-200°C. , The anti-thread element is mixed and pressurized so that the material pressure is about 10Mpa, and the screw speed is controlled at about 100rpm. After shearing and reacting for about 10min, the deeply activated rubber powder is extruded from the die. Subsequently, the deep activated rubber powder is metered into the second screw extruder through the connector, and at the same time adjust the feeding speed of the hopper to add SBS and interfacial phase according to the weight ratio of SBS, deep activated rubber powder and interfacial co...

Embodiment 2

[0038] Pretreat rubber powder, softening oil, and activator in a high-speed mixer at 70°C for 15 minutes according to the weight ratio of 100:10:1, and add them to the first screw extruder, and extrude from the die after shearing and reacting. Activated rubber powder. Subsequently, the deep activated rubber powder is metered into the second screw extruder through the connector, and at the same time adjust the feeding speed of the hopper according to the weight ratio of SBS, deep activated rubber powder, and interfacial compatibilizer by adding SBS and interfacial compatibilizer agent, uniformly mixed, extruded, and water-cooled granulated to prepare a storage-stable, aging-resistant composite SBS particle asphalt modifier. The process parameters of each step are basically the same as in Example 1. Weigh 10% storage-stable, aging-resistant composite SBS particle asphalt modifier according to the weight ratio of the base asphalt, add it to the base asphalt and cut it for 5 minu...

Embodiment 3

[0040] Pretreat rubber powder, softening oil, and activator in a high-speed mixer at 70°C for 15 minutes according to the weight ratio of 100:15:3, and add them to the first screw extruder, and extrude from the die to a depth of Activated rubber powder. Subsequently, the deeply activated rubber powder is metered into the second screw extruder through the connector, and at the same time adjust the feeding speed of the hopper to add SBS and interface compatibilizer according to the weight ratio of SBS, deep activated rubber powder and interfacial compatibilizer 28:68:4 agent, uniformly mixed, extruded, and water-cooled granulated to prepare a storage-stable, aging-resistant composite SBS particle asphalt modifier. The process parameters of each step are basically the same as in Example 1. Weigh 12% storage-stable, aging-resistant composite SBS particle asphalt modifier according to the weight ratio of the base asphalt, add it to the base asphalt and cut it for 5 minutes, then s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com