Continuous temperature-adjustable high-vacuum low-temperature micro-nano indentation test method and device

A testing device, micro-nano technology, applied in the direction of testing material hardness, etc., to achieve the effect of simple structure, good application prospect, high indentation load and displacement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

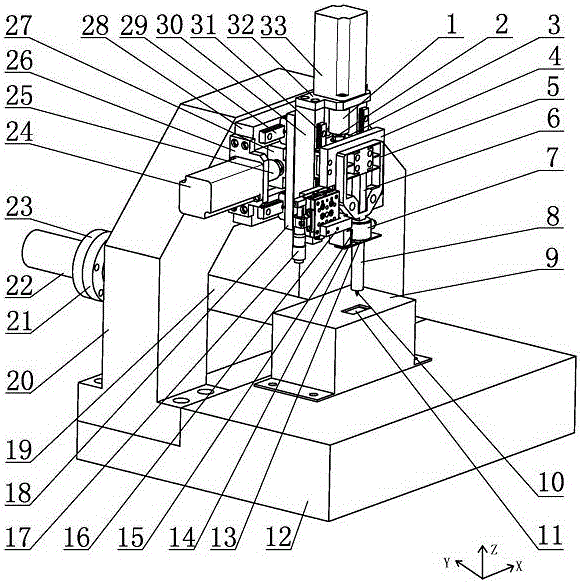

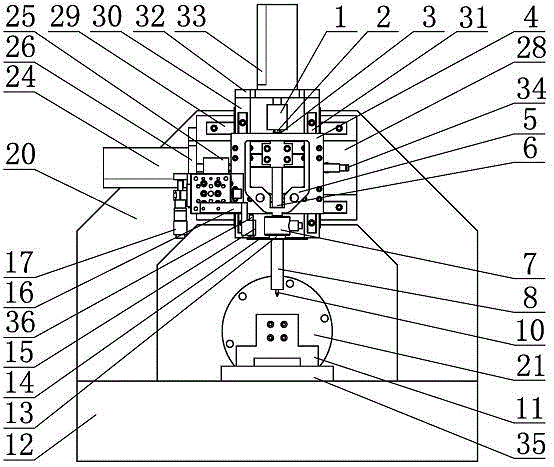

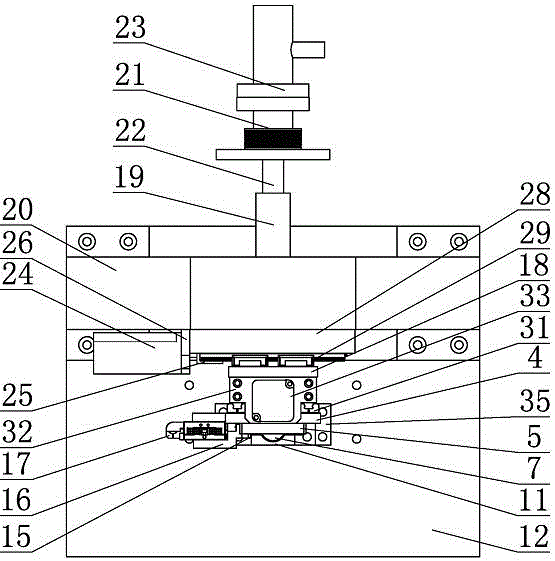

[0035] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0036] see Figure 1 to Figure 9 As shown, the continuous temperature-adjustable high-vacuum and low-temperature micro-nano indentation test device of the present invention works in a vacuum, and the frame is L-shaped as a whole. The thermostat performs precise contact temperature adjustment on the sample; it is mainly composed of X-direction precision adjustment module, Z-direction precision press-in drive module, displacement signal and force signal precision detection module, variable temperature loading platform, cryostat and support module; Continuously and accurately change the temperature of the material to reproduce the low-temperature working environment of the material, carry out the low-temperature micro-nano indentation test in the vacuum environment, and collect the indentation displacement signal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com