Sea-buckthorn juice and preparation method thereof

A technology of seabuckthorn juice and seabuckthorn, which is applied in the field of seabuckthorn juice and its preparation, can solve the problems that seabuckthorn resources have not been developed and the taste of juice has not been improved, and achieve the effects of reducing sour taste, delicate taste, and increasing lactic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

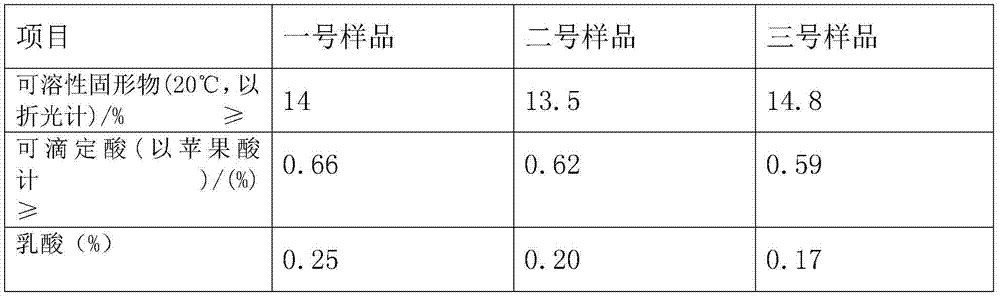

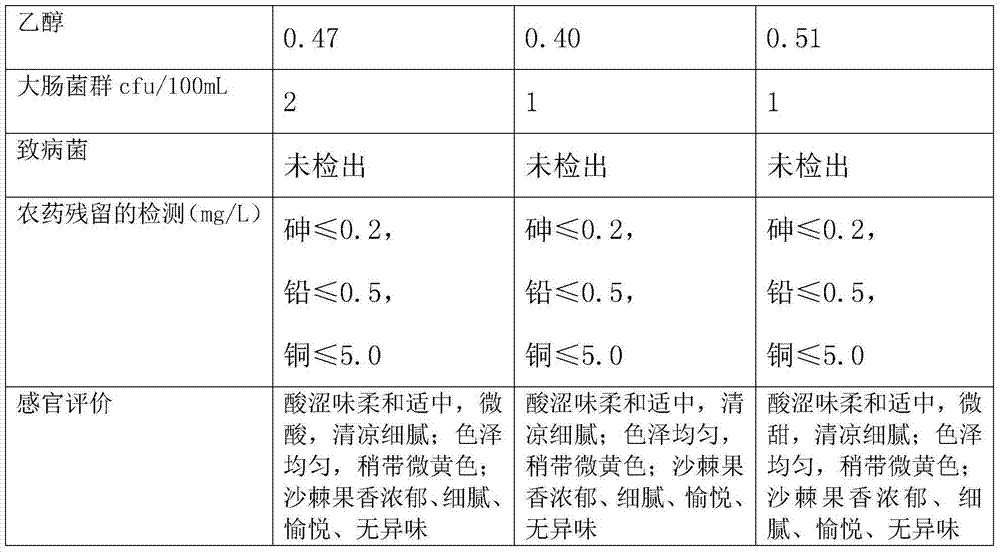

[0031] A preparation method of seabuckthorn fruit juice. Three parts of seabuckthorn fruit raw materials with the same product appearance and the same quality, labeled No. 1 sample, No. 2 sample, and No. 3 sample, are respectively carried out in the following steps:

[0032] Raw material pretreatment: after mixing clean seabuckthorn with water, the mixing ratio of clean seabuckthorn and water for sample No. 1 is 0.5:1 by mass ratio, the mixture ratio of clean seabuckthorn and water for sample No. The mixing ratio of clean seabuckthorn and water is 1:0.5 by mass, heated to 70-90°C for precooking, and beaten to obtain primary seabuckthorn slurry;

[0033] Pectinase treatment: add pectinase to the seabuckthorn slurry and let it stand at 35-55°C to obtain a secondary seabuckthorn slurry, wherein the amount of pectinase in No. 1 sample is 0.4 per 100g of the primary seabuckthorn slurry. g pectinase, the addition amount of No. 2 sample pectinase is to add 0.5g pectinase in every 100...

Embodiment 2

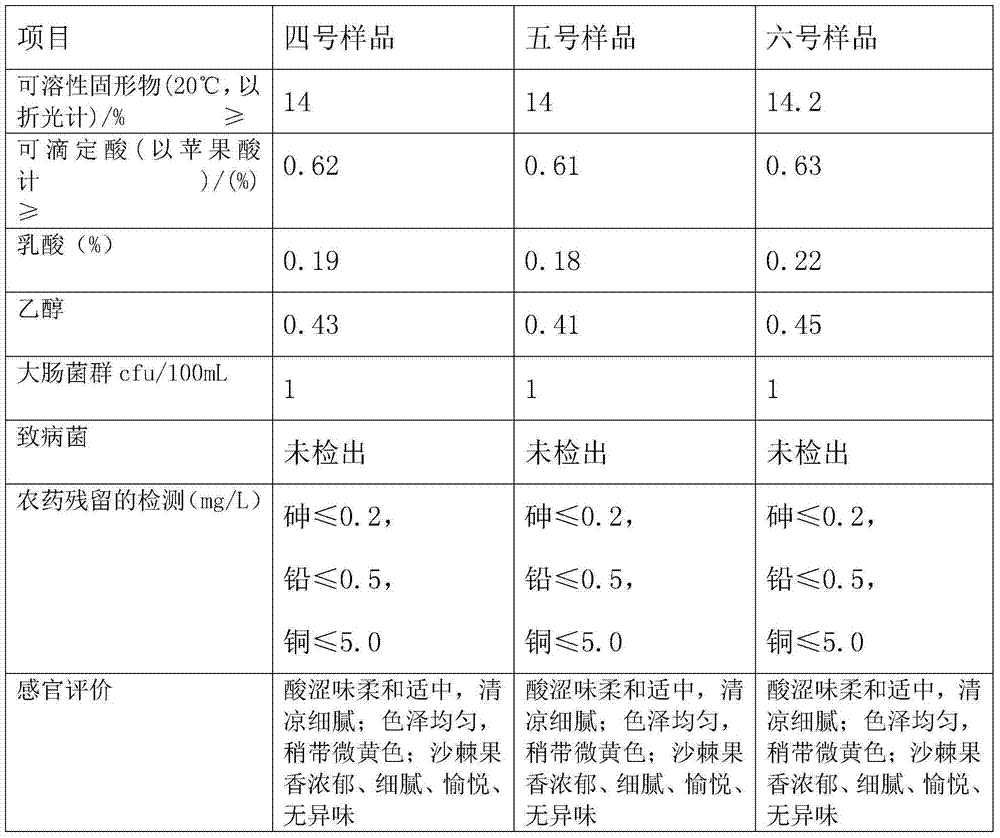

[0043] Take fresh seabuckthorn fruit with orange-yellow pulp, remove blemishes and mildew, wash it with clean water, add water of equal quality to it, mix well, heat to 80°C for two minutes, and then perform beating treatment to obtain primary Seabuckthorn slurry; then add 0.4g pectinase to every 100g of primary seabuckthorn slurry, stir evenly, and let stand for 2 hours to obtain secondary seabuckthorn slurry; then centrifuge the obtained secondary seabuckthorn slurry at 400r / min , Centrifugal 15min, obtains three grades of seabuckthorn slurries; After the three grades of seabuckthorn slurries are diluted and processed (the amount of water added is 30g of water in every 80g of three grades of seabuckthorn slurries), adding quality is the calcium carbonate of 1.5% of the three grades of seabuckthorn slurries, and stirring slowly Add sucrose, adjust the sugar content to 10%, and obtain the fourth-grade seabuckthorn slurry; divide the obtained fourth-grade seabuckthorn slurry int...

Embodiment 3

[0048] Take respectively three parts of the five-grade seabuckthorn serum of No. 4 sample, No. 5 sample and No. 6 sample of Example 2, and six parts of No. 4 sample are marked as 4-1 sample, 4-2 sample, 4-3 sample, 4 - 4 samples, 4-5 samples, 4-6 samples, 4-7 samples, three copies of the fifth sample are labeled 5-1 samples, 5-2 samples, 5-3 samples, 5-4 samples, 5-5 Sample, 5-6 sample, 5-7 sample, three copies of sample number six are labeled 6-1 sample, 6-2 sample, 6-3 sample, 6-4 sample, 6-5 sample, 6-6 sample, For samples 6-7, add stabilizers shown in Table 3 respectively therein to obtain seabuckthorn fruit juice.

[0049] Table 3 Stabilizer Addition Comparison Table

[0050]

[0051]

[0052] See Table 4 and Table 5 for the obtained sensory evaluation of seabuckthorn juice stability.

[0053] Table 4 Stabilizer Scoring Criteria

[0054] Score (points) standard 0-29 Obvious layering, more pigment and pulp particles precipitated, and more seabuckt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com