A method and device for automatic dedusting of pyrolysis gas in the production of hexafluoropropylene

A technology of automatic dust removal and hexafluoropropylene, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of manual and regular cleaning of dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

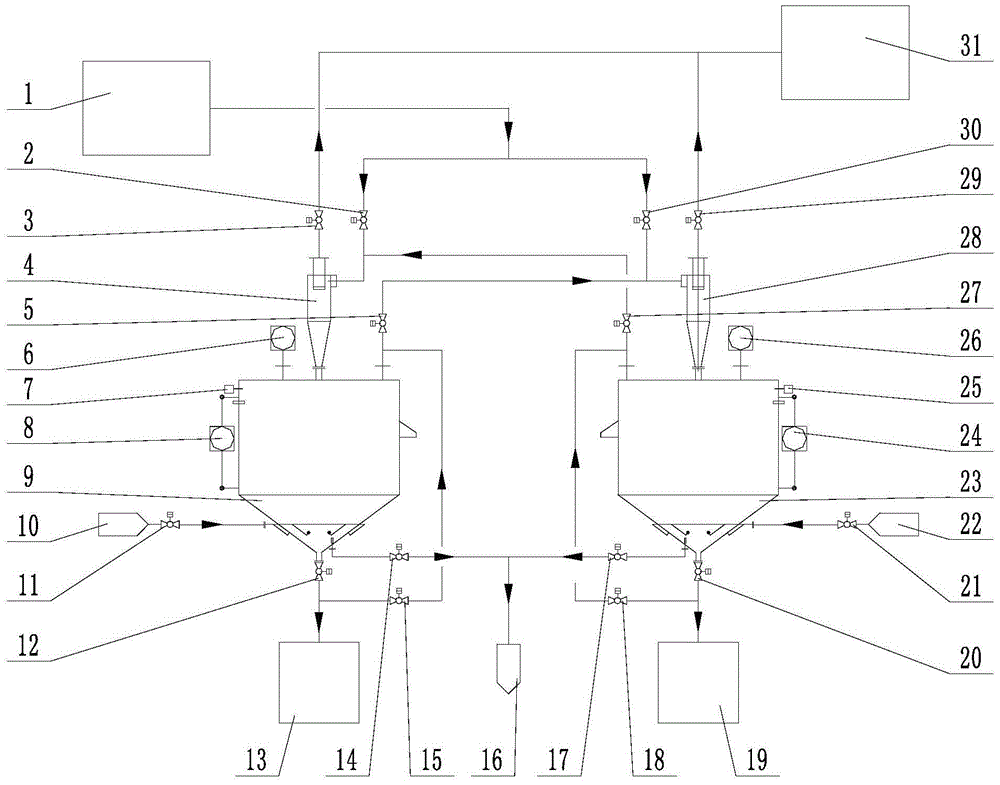

[0023] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0024] The most critical idea of the present invention is to replace the existing packed tower or simple cyclone separator with a high-efficiency cyclone separator. The water and dust separated by the high-efficiency cyclone separator can be automatically removed. Drainage and dust cleaning will not affect the normal operation of the equipment, ensure that the equipment does not stop, and avoid manual operation, prevent the leakage of cracked gas containing highly toxic octafluoroisobutene, realize automatic dust removal of cracked gas in the production of hexafluoropropylene, and ensure the safety of the production environment safety.

[0025] The automatic dedusting method of pyrolysis gas in the production of hexafluoropropylene provided by the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com