VOCs tail gas treatment apparatus

A technology for exhaust gas treatment and equipment, applied in lighting and heating equipment, air quality improvement, combustion methods, etc., can solve the problems of secondary pollution that consumes a lot of resources, low removal rate, low efficiency, etc., and achieves light weight and equipment volume. Small, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

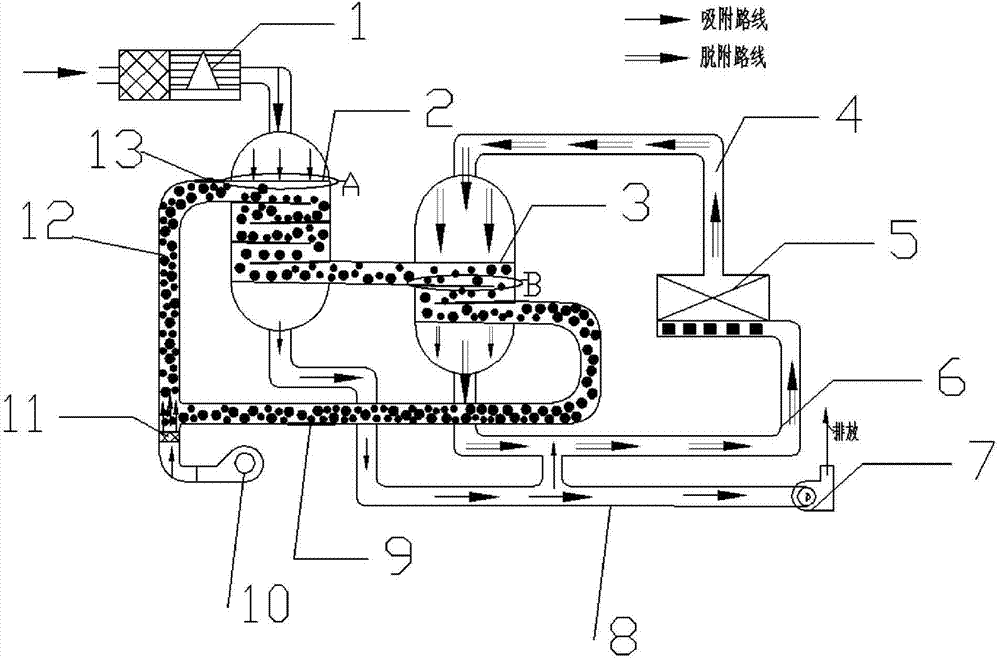

[0015] like figure 1 As shown, a VOCs tail gas treatment equipment described in the present invention mainly includes an exhaust gas pre-filter 1, an adsorption tank 2 (the number can be added according to the demand), a catalytic combustion device 5, and a desorption tank 3 (the number can be According to demand), the induced draft fan 7, the ACF particle circulation pipeline 12 and the blower 10 are combined into an integrated device, which is convenient for transportation and installation. Its structural feature is that the exhaust gas pre-filter 1 is connected to the adsorption tank 2, the bottom of the adsorption tank 2 is connected to the exhaust gas pipeline 8, and the exhaust gas pipeline 8 is divided into two routes, one of which is connected to the induced draft fan 7, and the other is connected to the catalytic combustion device 5 through the VOCs pipeline 6 , the bottom of the desorption tank 3 is connected to the VOCs pipeline 6, and the VOCs pipeline 6 is divided...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap