Preparation method for nonionic bitter almond oil microemulsion

A non-ionic, bitter almond oil technology, applied in the direction of mixing methods, emulsion delivery, skin care preparations, etc., can solve problems such as insoluble in water, little bitter almond oil, greasy, etc., and achieve a clear and transparent appearance , Improve water solubility and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

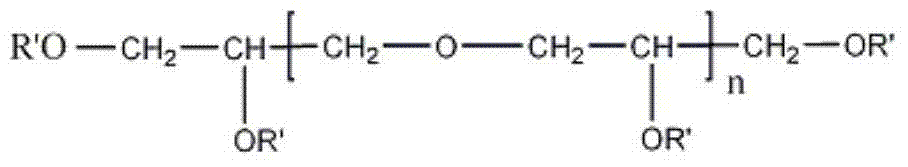

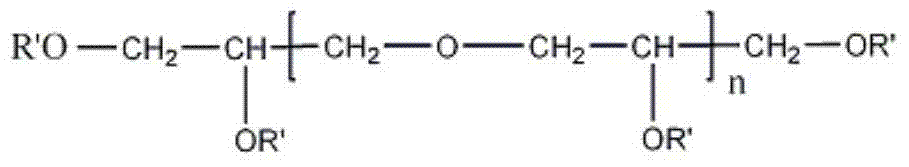

Image

Examples

Embodiment 1

[0026] 1) To improve the water solubility of bitter almond oil: add 1 mL of bitter almond oil and 2 mL of hydrogenated castor oil (specifically PEG-40) into a reactor equipped with a thermometer and a magnetic stirrer, mix well, control the temperature and heat at 70°C for 30 min.

[0027] 2) Emulsified bitter almond oil: mix the product from the previous step with non-ionic emulsifier Q-185S at a mass ratio of 3:0.06, melt at 70°C, stir evenly, and then use non-ionic emulsifier: co-emulsifier A co-emulsifier (glycerin) was added at a mass ratio of =0.06:9, then water was added to 100 mL, and homogeneously stirred for 5 min to obtain a clear and transparent microemulsion of bitter almond oil.

Embodiment 2

[0029] 1) To improve the water solubility of bitter almond oil: add 1 mL of bitter almond oil and 8 mL of hydrogenated castor oil (specifically PEG-40) into a reactor equipped with a thermometer and a magnetic stirrer, mix well, control the temperature and heat at 65°C for 40 min.

[0030] 2) Emulsifying Bitter Almond Oil: Mix the product from the previous step with the nonionic emulsifier Q-18D at a mass ratio of 9:0.06, melt at 65°C, stir evenly, and then use nonionic emulsifier:co-emulsifier= A co-emulsifier (glycerin) was added at a mass ratio of 0.06:10, then water was added to 100 mL, and homogeneously stirred for 4 min to obtain a clear and transparent microemulsion of bitter almond oil.

Embodiment 3

[0032] 1) Improve the water solubility of bitter almond oil: Add 1.5mL bitter almond oil and 4mL hydrogenated castor oil (specifically PEG-60) into a reactor with a thermometer and a magnetic stirrer, mix well and control the temperature at 50°C for 50min .

[0033] 2) Emulsified bitter almond oil: mix the product from the previous step with the nonionic emulsifier Q-18F at a mass ratio of 5.5:0.04, melt at 50°C, stir evenly, and then use nonionic emulsifier: co-emulsifier = Add a co-emulsifier (1,3-butanediol) at a mass ratio of 0.04:4, then add water to 100 mL, and stir homogeneously for 3 minutes to obtain a clear and transparent microemulsion of bitter almond oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com