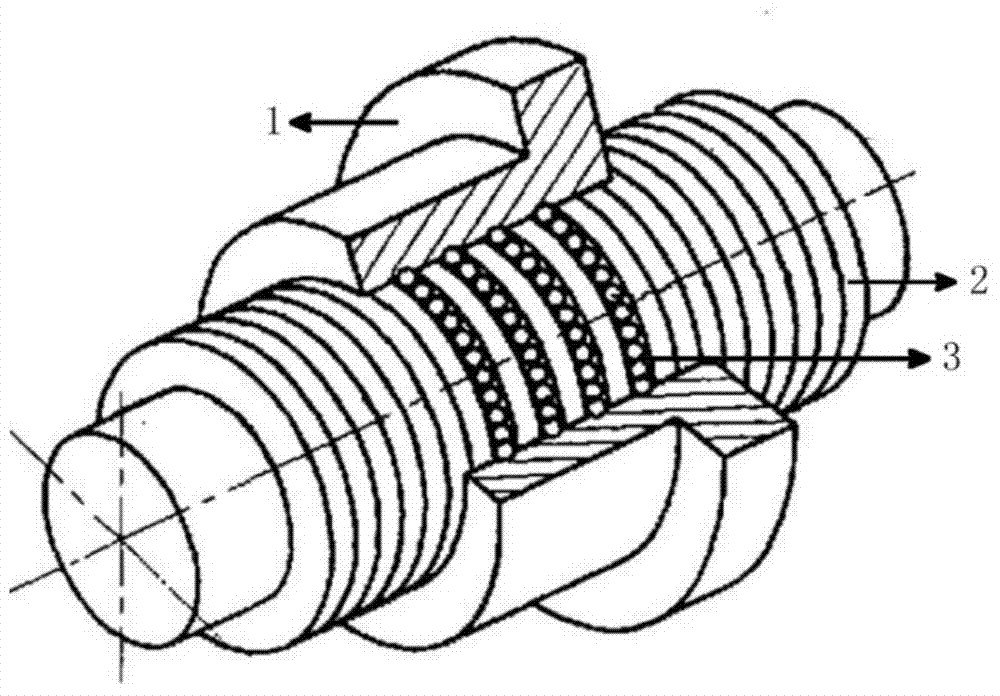

Laser-electric arc compound welding gun

A hybrid welding and laser welding technology, applied in the field of material processing, can solve the problems of difficult commercial application, complex arc electrode processing technology, welding quality impact, etc., to reduce the cleaning cycle, meet the needs of welding and 3D additive manufacturing, The effect of improving sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

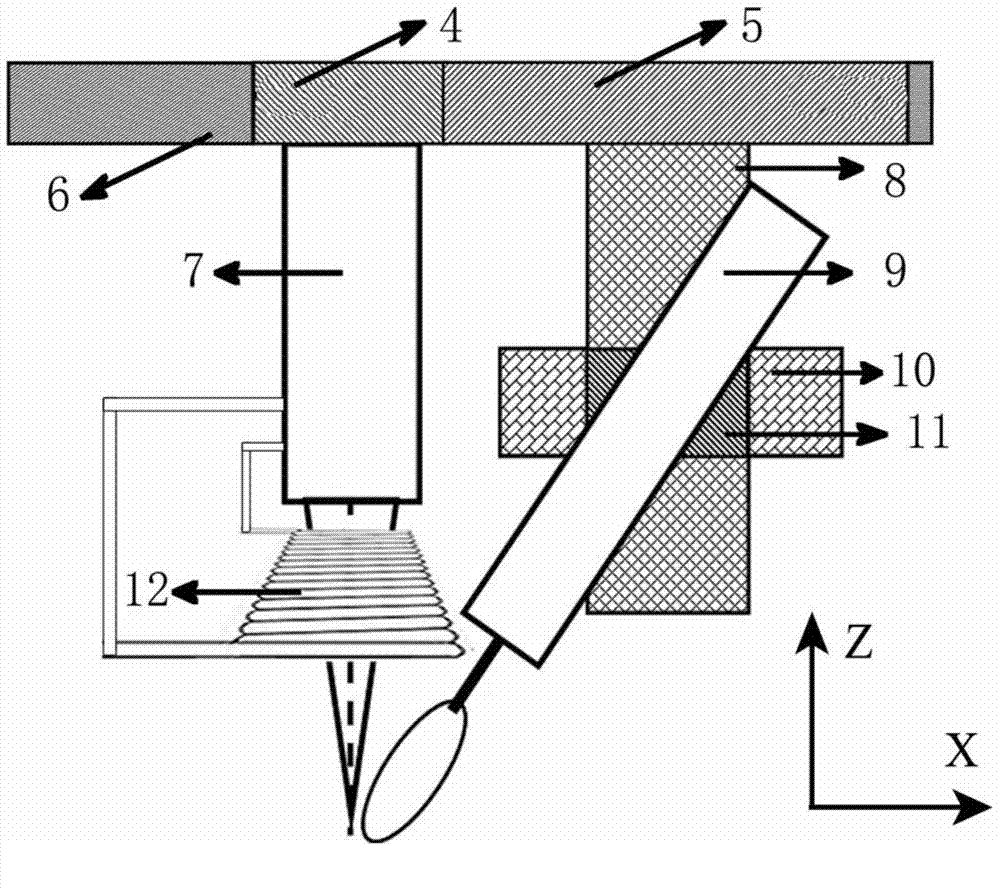

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The present invention improves in that:

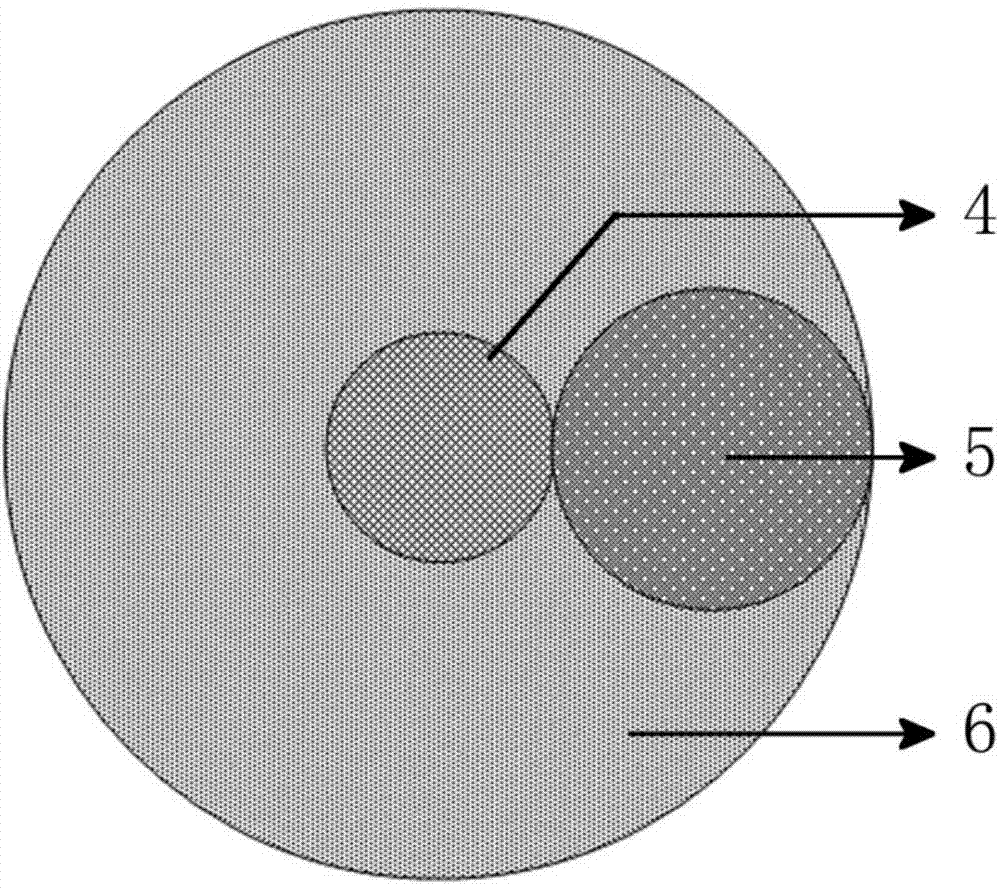

[0027] Through three ball screw pair linear guide mechanisms driven by stepping motors or servo motors arranged perpendicular to each other along the three rectangular coordinate axes of x, y, z, the spatial position of the laser focus and the arc electrode can be along x, y The direction of the three rectangular coordinate axes of , z is precisely adjusted; at the same time, the arc electrode is freely rotated around the axis of the laser beam within 360° through the gear pair rotation adjustment mechanism driven by a stepping motor or a servo motor, realizing free adjustment of four degrees of freedom. In turn, the arbitrary adjustment of the spatial position and angle of the welding torch can be realized to ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com