Microwave-specific food package bag and manufacturing method thereof

A production method and packaging bag technology, which is applied in the field of food packaging bags, can solve the problems of time-consuming and laborious, unsealable packaging bags, and contamination, and achieve the effects of complete safety of components, avoiding explosions, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

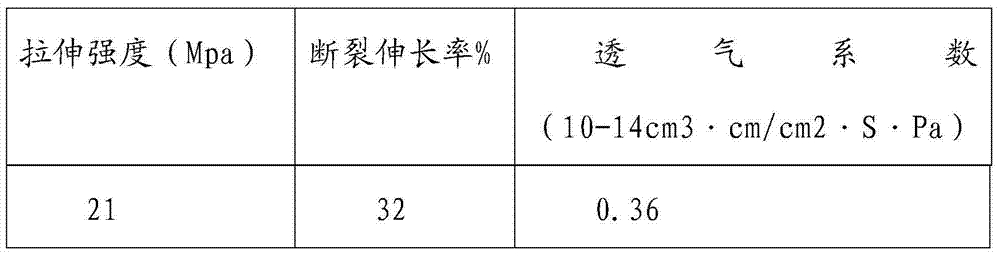

Examples

Embodiment 1

[0025] Making microwave special food packaging bags includes the following steps:

[0026] 1) Make the plastic packaging bag body;

[0027] 2) A plurality of ventilation holes are opened on the surface of the plastic packaging bag body, and the diameter of the ventilation holes is kept at 0.3-0.5mm;

[0028] 3) Apply the film paste on the position corresponding to the vent holes on the inner surface of the packaging bag body, and the film paste will completely cover the vent holes;

[0029] 4) Put the packaging bag coated with film slurry in the drying oven, dry at 50°C for 30 minutes, and then dry at 65°C for 10 minutes. After the film on the air hole is formed, take out the packaging bag and start food packaging;

[0030] Wherein said film slurry adopts following method to make:

[0031] 1) Mix corn starch and cross-linked starch in a ratio of 4:1, dissolve in water and adjust to starch slurry with a concentration of 25%;

[0032] 2) Adjust the pH value of 25% starch slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com