High-quality single-compound explosive recrystallization method

A simple explosive and recrystallization technology, applied in organic chemistry methods, organic chemistry, etc., can solve the problems of low formability, large particle size, high acidity of DNTF crystals, etc., and achieve the effect of safe production and low mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] This embodiment is carried out with reference to the following composition by weight: 99.5% crude DNTF, ethyl acetate as organic solvent, and 0.5% polyethylene glycol. The preparation method of the present embodiment is as follows:

[0014] (1) DNTF dissolved

[0015] Weigh 100g of crude DNTF and 200g of ethyl acetate, put them in a 1000mL stainless steel container, heat in a water bath to dissolve the crude DNTF, heat the temperature of the water bath to 50°C-60°C, and stir for 30min-60min under high-speed shearing equipment.

[0016] (2) DNTF morphology control

[0017] After the DNTF is completely dissolved, add 0.5% polyethylene glycol, stir at 50°C to 60°C for 30min, and the stirring rate is 2000r / m.

[0018] (3) DNTF crystal precipitation

[0019] Add non-solvent deionized water until the solution is supersaturated, DNTF crystals are precipitated, and vacuum is applied to precipitate all the crystals.

[0020] (4) DNTF crystal drying

[0021] Stop evacuation,...

Embodiment 2

[0024] This embodiment is carried out with reference to the following composition by weight percentage: 99.5% DNTF crude product, organic solvent is ethyl acetate, 0.5% stearic acid. The preparation method of this embodiment refers to embodiment 1.

Embodiment 3

[0026] This embodiment is carried out with reference to the following composition by weight percentage: 99.5% DNTF crude product, organic solvent is acetone, and 0.5% polyethylene glycol. The preparation method of this embodiment refers to embodiment 1.

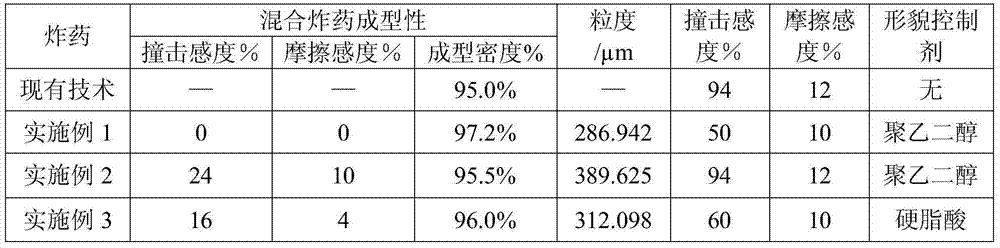

[0027] Table 1 Example performance data

[0028]

[0029] As can be seen from the above table, the high-quality DNTF explosive prepared by the method of the present invention has a smaller and uniform particle size and low mechanical sensitivity. Compared with the existing technology, the mixed explosive prepared from high-quality DNTF as the main explosive has high molding density, low mechanical sensitivity and good safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com