A kind of imitation silk fabric and production method thereof

A technology of imitating silk and fabrics, applied in the field of textiles, which can solve the problems of non-squeaky feeling of real silk fabrics and increase production costs, and achieve the effects of excellent resilience and silky feeling, improved silky feeling, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

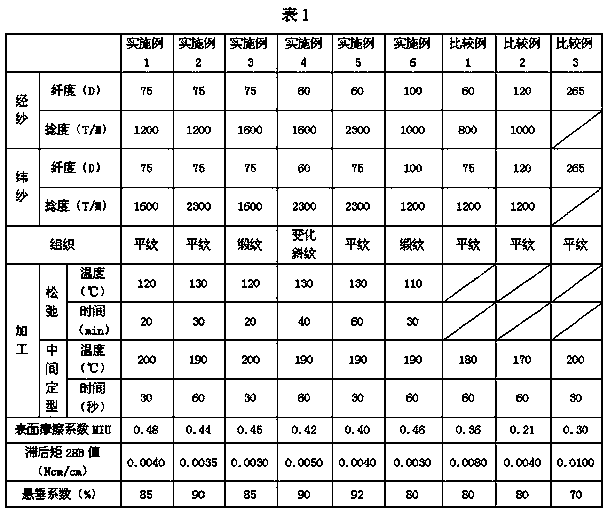

Embodiment 1

[0034] 30 denier cationic dyeable modified polyester semi-glossy pre-oriented yarn is selected as the decorative yarn, and 30 denier cationic dyeable modified polyester bright full-drawn yarn is used as the core yarn, and the decorative yarn is passed through After slow heat treatment with a contact hot plate temperature of 170°C and an overfeed rate of 20%, it is compounded with the core yarn at the interlacing nozzle to form a composite yarn with a denier of 75 denier. The length difference between the decorative yarn and the core yarn is 15%, and then the resulting composite yarn is twisted, the twist twist is 1200T / M when used as a warp yarn, and the twist twist is 1600T / M when used as a weft yarn, and the weft yarn is divided into S twist and Z twist, and plain weave is used for weaving The gray cloth is obtained, wherein the weft yarn S twist and Z twist are arranged at a ratio of 2:2 during weaving; the gained gray cloth is then processed through refining, relaxation, hi...

Embodiment 2

[0037]The composite yarn of Example 1 is twisted, the twist twist is 1200T / M when used as a warp yarn, and the twist twist is 2300T / M when used as a weft yarn, and the weft yarn is divided into S twist and Z twist, and the plain weave is used for weaving. Gray cloth is obtained, wherein the weft yarn S twist and Z twist are arranged at 2:2 during weaving; then the gained gray cloth is formed through engineering such as refining, relaxation, high-temperature intermediate setting, dyeing, and post-finishing processing to form the imitation silk fabric of the present invention, wherein the relaxation condition It is: temperature 130°C, time 30min; intermediate shaping conditions are: temperature 190°C, time 60 seconds; other conditions are the same as in Example 1.

[0038] The surface friction coefficient of the obtained fabric is 0.44, the hysteresis moment 2HB value is 0.0035 Ncm / cm, and the drape coefficient is 90%.

Embodiment 3

[0040] The composite yarn of Example 1 is twisted, and the warp and weft yarns are both twisted and twisted at 1600T / M, wherein the weft yarn is divided into S twist and Z twist, and the satin weave is used to weave gray cloth. 2:2 arrangement; then the gained gray cloth is processed through refining, relaxation, high-temperature intermediate setting, dyeing, finishing and other projects to form the imitation silk fabric of the present invention, and the processing conditions are the same as in Example 1.

[0041] The surface friction coefficient of the obtained fabric is 0.45, the hysteresis moment 2HB value is 0.0030 Ncm / cm, and the drape coefficient is 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drape coefficient | aaaaa | aaaaa |

| drape coefficient | aaaaa | aaaaa |

| drape coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com