Foundation near foundation pit slope and reinforcement method thereof

A foundation reinforcement and foundation pit edge technology, applied in excavation, infrastructure engineering, construction, etc., can solve safety problems, self-heavy, unsafe slopes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

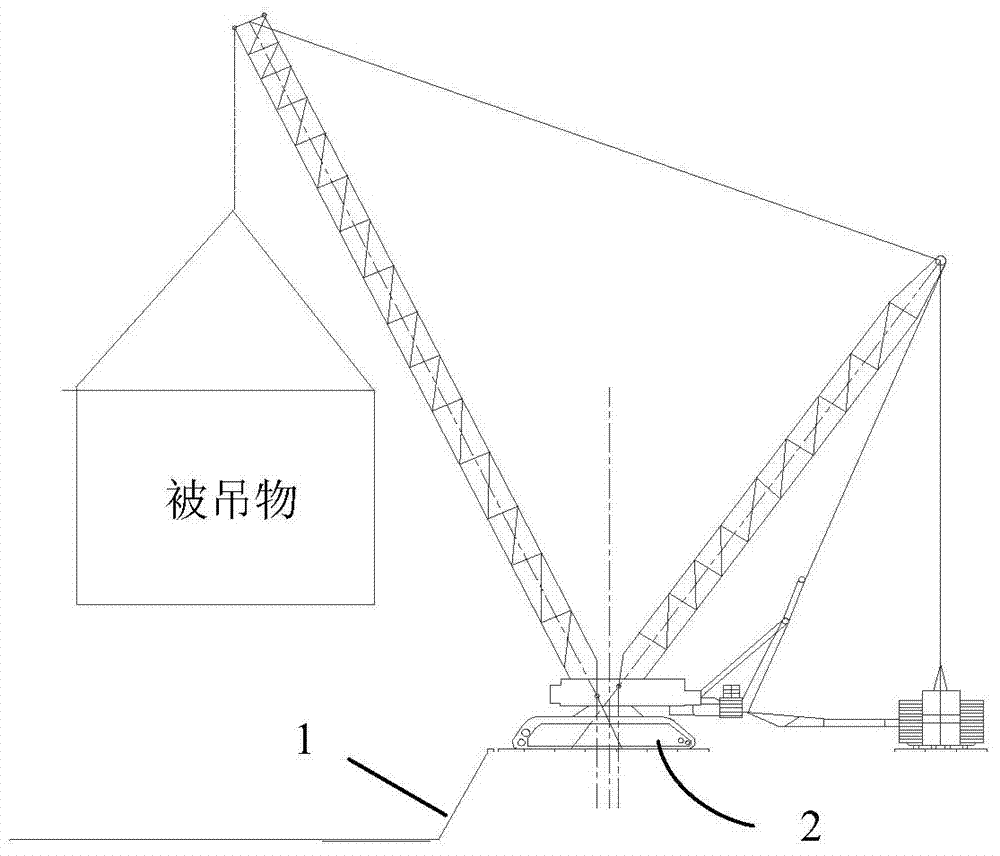

[0024] The present invention is aimed at the overall reinforcement of the hoisting foundation when the hoisting machine is close to the side slope of the excavated foundation pit, which includes the use of micro piles for reinforcement at the crane station site, the reinforcement of the foundation pit side slope area of the hoisting site, and the concrete in the walking area of the crane. Pouring, so that the crane station point and the overall layout of the walking area form an overall reinforcement, thereby ensuring the safety of the crane station on the edge of the foundation pit.

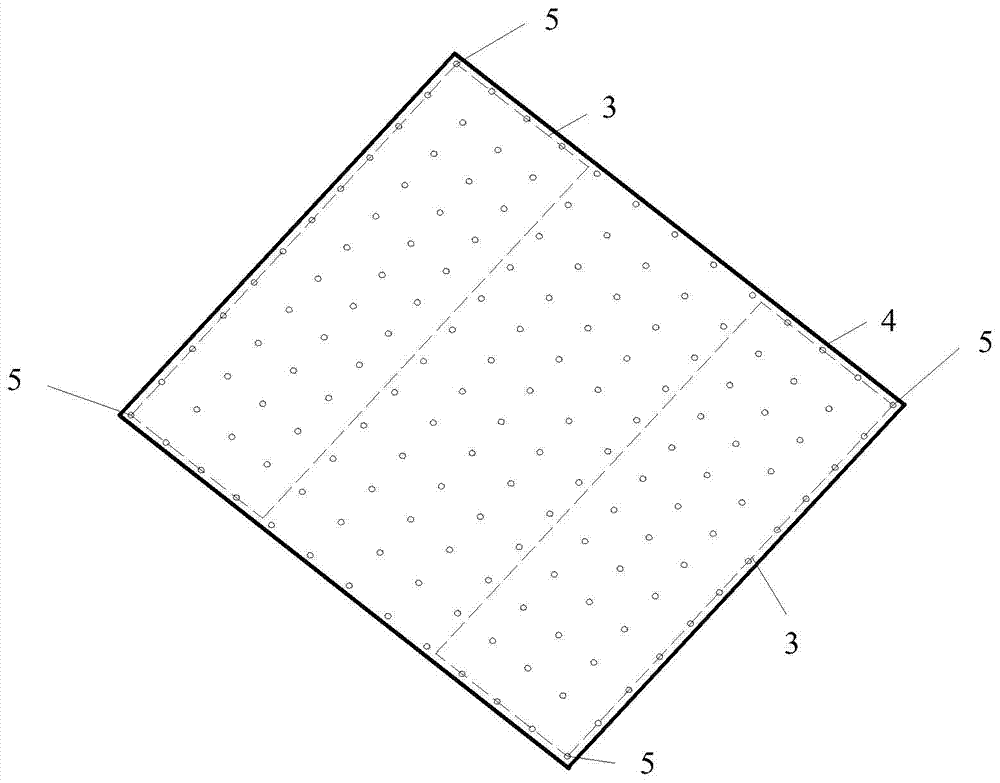

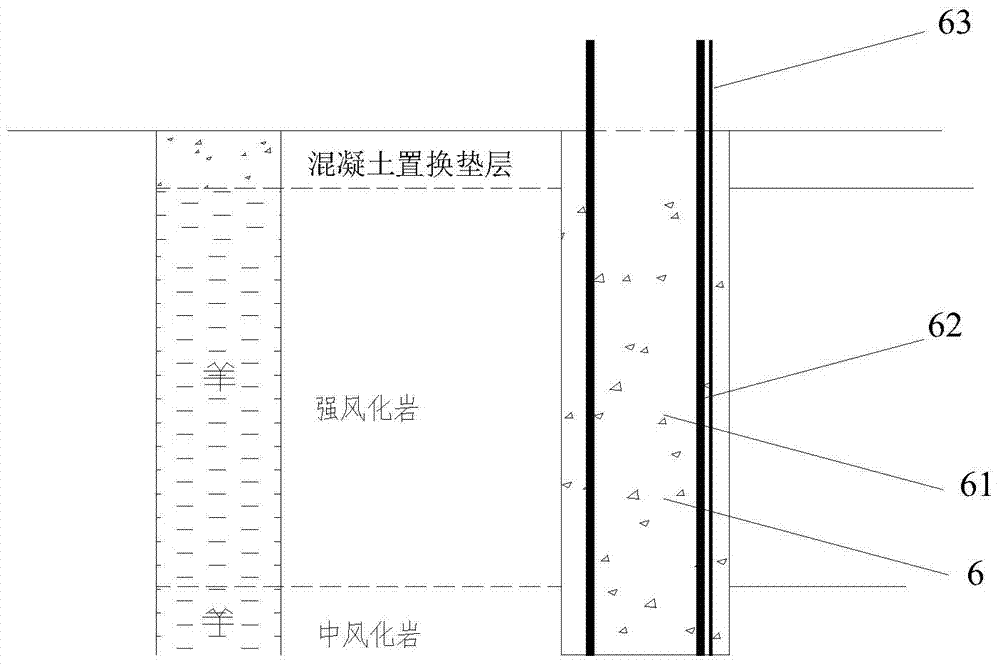

[0025] The crane station point is reinforced by micro piles, such as figure 2 , image 3 , Figure 4 As shown, including the use of hole-forming equipment to carry out the construction of strong micro-steel piles at the reinforcement points of the hoisting site. In the embodiment of the present invention, the horizontal spacing of the miniature steel piles 6 is 1.6m, the diameter of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com