Optical fiber sensor, manufacturing method and simultaneous measuring method for liquid temperature and refractive index

An optical fiber sensor and refractive index technology, applied in the field of optical fiber sensing and biochemistry, can solve the problems of increasing the volume of the sensor, being susceptible to external temperature interference, increasing the difficulty and cost of sensor fabrication, and achieving simple structure and increased fabrication. Cost and difficulty, easy-to-create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

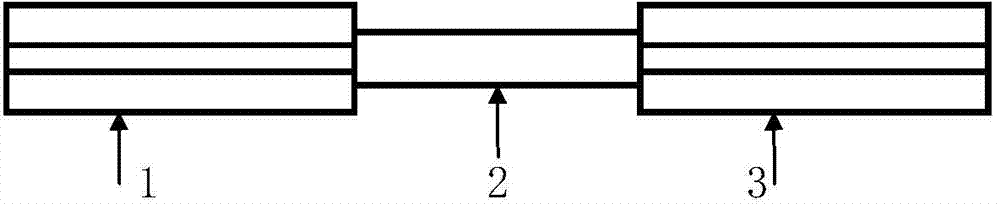

[0022] Such as figure 1 As shown, it is a schematic structural diagram of the novel optical fiber sensor of the present invention, and the adopted single-mode-coreless-single-mode optical fiber structure includes an input optical fiber 1, an output optical fiber 3, and a coreless optical fiber 2 arranged between them. The manufacturing method of the optical fiber sensor is summarized as follows: it is obtained by directly fusing a section of coreless optical fiber 2 into a section of single-mode optical fiber to form a single-mode-coreless-single-mode optical fiber structure; Eccentric fusion splicing; Among them, the coreless fiber is a multi-mode optical waveguide sensitive to the external refractive index, which is a commercial coreless fiber, or the cladding of the ordinary multi-mode fiber is removed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com