Wavelength division multiplexer and optical module

A technology of wavelength division multiplexer and light guide block, which is applied in the field of optical communication, can solve the problems of low reliability of wavelength division multiplexer, large beam offset, unstable beam, etc., and achieves easy packaging, stable optical path, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

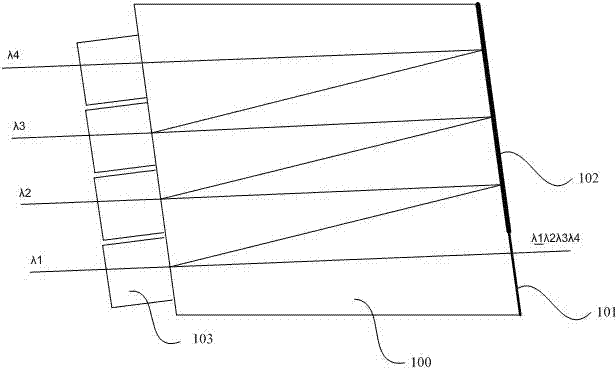

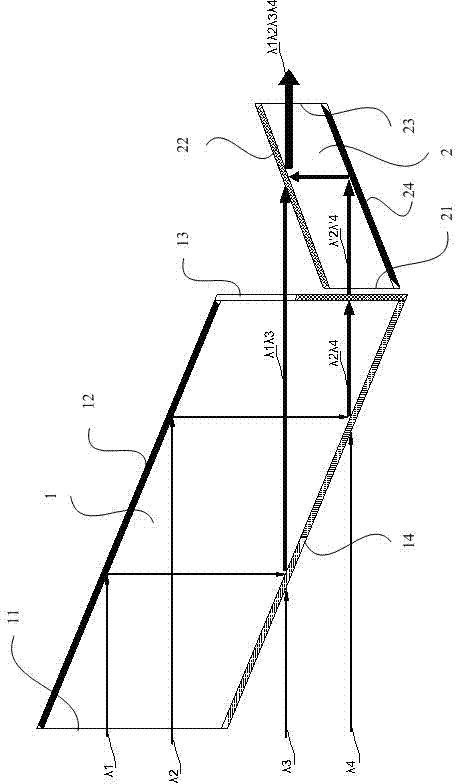

[0021] Such as figure 2 As shown, the wavelength division multiplexer in this embodiment includes a first light guide block 1 and a second light guide block 2, and the side wall of the first light guide block 1 forms a first light surface 11, a second light surface 11, and a second light guide block that are connected in sequence. Two light surfaces 12, a third light surface 13 and a fourth light surface 14, the side walls of the second light guide block 2 form a light surface one 21, a light surface two 22, a light surface three 23 and a light surface four connected in sequence 24. The optical surface one 21 is located on one side of the third optical surface 13; the first optical surface 11 has an anti-reflection coating layer, the second optical surface 12 has a reflective coating layer, and the second optical surface 12 has a reflective coating layer. An anti-reflection film layer and a half-wave plate are sequentially arranged on the three optical surfaces 13 along the l...

Embodiment 2

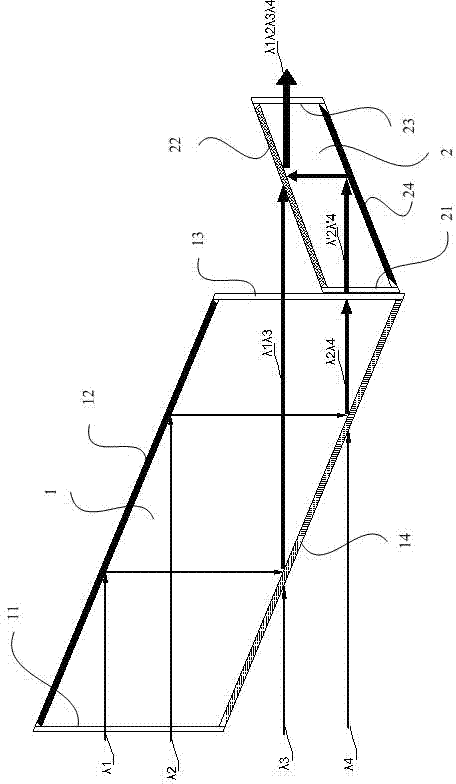

[0026] Such as image 3As shown, the wavelength division multiplexer of this embodiment is based on the above-mentioned embodiment, and the difference from the above-mentioned embodiment is that there is only an anti-reflection coating layer on the third optical surface 13 without a half-wave plate, and the optical surface-21 is set There are half wave plates.

[0027] Specifically, the wavelength division multiplexer of this embodiment is provided with a half-wave plate on the optical surface 21. After the light beam of λ2λ4 enters the optical surface 21, it passes through the action of the half-wave plate, so that the light beam of λ2λ4 is polarized by P The light becomes S polarized light. The specific process is as follows: the light beams of λ1 and λ2 are vertically incident on the first light surface 11 of the first light guide block 1 coated (or pasted) with the AR anti-reflection film layer, and are respectively transmitted to the second light surface 12 by the second...

Embodiment 3

[0029] According to design requirements, the first smooth surface 11, the second smooth surface 12, the third smooth surface 13 and the fourth smooth surface 14 can be distributed clockwise or counterclockwise. Similarly, smooth surface one 21, smooth surface two 22, smooth surface Three 23 and smooth four 24 can also be distributed clockwise or counterclockwise. Such as figure 2 As shown, the first light surface 11, the second light surface 12, the third light surface 13 and the fourth light surface 14 are distributed in a clockwise direction. Similarly, as image 3 As shown, smooth surface 1 21 , smooth surface 2 22 , smooth surface 3 23 and smooth surface 4 24 can also be distributed in a clockwise direction.

[0030] Preferably, in order to facilitate clamping and assembly, there is a prism (not shown) covering the polarization multiplexing film layer on the optical surface 22. The prism can be a triangular structure, and one surface of the prism is connected to the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com