Composite fast recovery diode and preparation method thereof

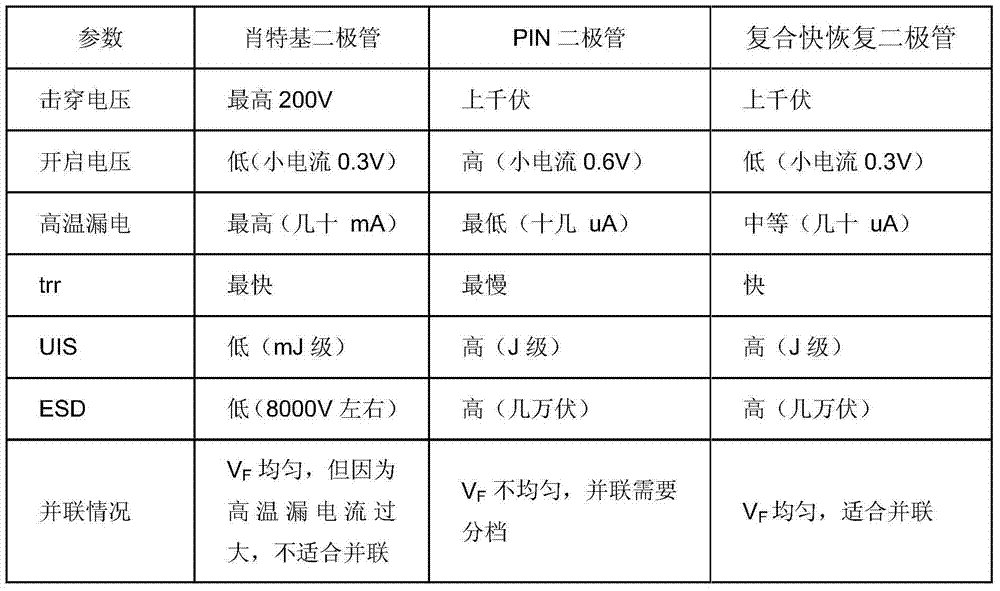

A recovery diode and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor consistency of on-state voltage drop, long reverse recovery time, and device reliability decline, and achieve UIS improvement , Reduce the recovery time, reduce the effect of on-state pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

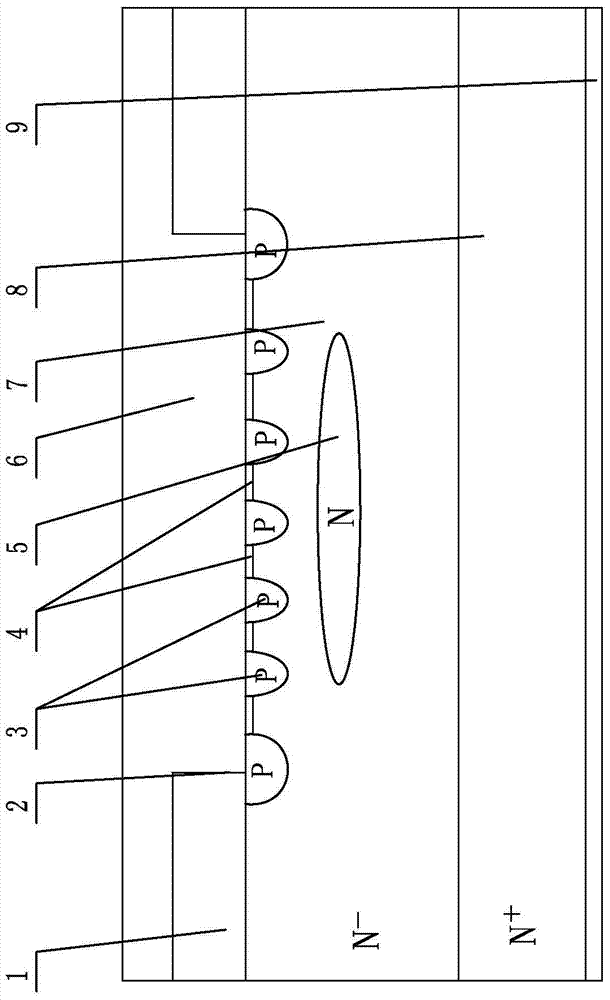

[0029] See figure 1 Shown, the preparation method of composite fast recovery diode of the present invention,

[0030] (1) Oxidation and lithography active area: After cleaning the silicon wafer with epitaxial layer, perform oxidation treatment to form a field oxide layer on the front side of the silicon wafer, and then photoetch and etch the active area on the front side of the silicon wafer window, the silicon wafer is an N+ type substrate silicon wafer.

[0031] (2) N-type impurity ion implantation: use an ion implanter to implant N-type impurity ions into the active area, the implantation energy is: 100-500kev, and the implantation dose is 1E12-5E14cm -2 .

[0032] (3) N push junction: Put the silicon wafer into a high-temperature diffusion furnace to push the N-type impurity ions to form a charge accumulation region. The concentration of N-type impurity ions in the charge accumulation region is higher than that of the epitaxial layer. , the junction depth of the N-type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com