All-optical monolithic integrated optoelectronic device and manufacturing method thereof

A technology of monolithic integration and optoelectronic devices, applied in the direction of electric solid state devices, electrical components, semiconductor devices, etc., can solve the problems of low device quality, unfavorable miniaturized equipment manufacturing, high cost, etc., achieve process simplification, convenient and practical application, Reduce the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

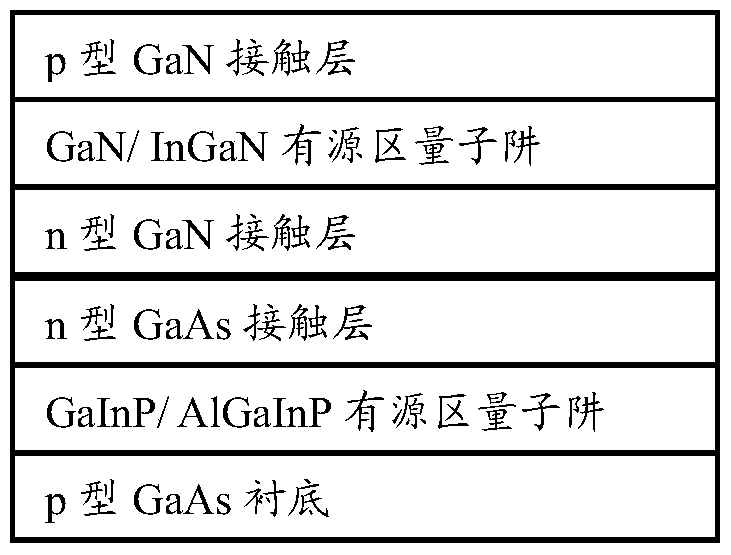

[0021] The invention utilizes the direct preparation of GaInP / AlGaInP (GaInP or AlGaInP) active area quantum well on p-GaAs substrate, and prepares n+GaAs on it, and realizes the two-color monolithic integrated optoelectronic device. Further, the present invention utilizes the GaN / GaAs direct bonding method to effectively combine GaN / GaAs two materials with large difference in bandgap energy through the influence of the selection of doping concentration and annealing time on the interface resistance, and solve the problem of Due to the mismatch problem caused by different crystal lattices, the second-generation semiconductor GaAs material is effectively combined with the third-generation semiconductor GaN material. Compared with the existing technology, it also reduces the high cost caused by using multiple different substrates in mechanical connections Cost, the purpose of cost reduction and process simplification is realized. The present invention also provides an all-optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com