Special walnut boiling process

A processing technology and walnut technology, applied in the field of processing technology of walnut products, can solve the problems of destroying walnut nutrients, reducing edible value, inconvenience in eating, etc., and achieving the effects of enhancing appetite, high yield and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw materials: walnut 28.3kg, aniseed 0.29kg, pepper 0.23kg, cumin 0.29kg, pepper 0.12kg, ginger 0.06, salt 2.6kg.

[0030] a. Weigh various raw materials, mix all auxiliary materials except walnuts, add 885kg of hot water at 100°C, stir evenly, and make soaking liquid;

[0031] b. heating and boiling the soaking feed liquid prepared in step a, and maintaining vigorous boiling for 2 minutes to obtain a boiling feed liquid;

[0032] c. After the feed liquid stops boiling, add walnuts for soaking at 75°C for 12 hours;

[0033] d. Take out the soaked walnuts, centrifuge at 500 rpm for 20 minutes, then spread the walnuts on a mesh sieve with holes and let them stand for 7 hours at a temperature of 25°C and a humidity of 40% to control the water;

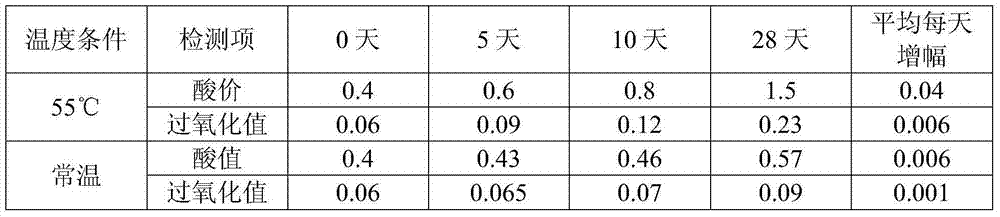

[0034] The walnuts after water control are vacuum-packed in a 300,000-class purification workshop. The packaging material is a double-layer composite retort bag with a thickness of 9 silk. Store at room temperature away from lig...

Embodiment 2

[0036] Raw materials: walnut 28.2kg, aniseed 0.28kg, pepper 0.22kg, cumin 0.28kg, pepper 0.10kg, ginger 0.05, salt 2.5kg.

[0037] a. Weigh various raw materials, mix all auxiliary materials except walnuts, add 790.8kg of hot water at 90°C, stir evenly, and make soaking liquid;

[0038] b. heating and boiling the soaking feed liquid made in step a, and keeping boiling for 2 minutes to obtain the boiling feed liquid;

[0039] c. After the feed liquid stops boiling, add walnuts for soaking at 70°C for 12 hours;

[0040] d. Take out the soaked walnuts, centrifuge at 500 rpm for 20 minutes, then spread the walnuts on a mesh sieve with holes and let them stand for 6 hours at a temperature of 20°C and a humidity of 35% to control the water;

[0041] Packaging, sterilization and storage are the same as in Example 1.

Embodiment 3

[0043] Walnut 28.4kg, aniseed 0.30kg, pepper 0.24kg, cumin 0.30kg, pepper 0.12kg, ginger 0.07, salt 2.7kg.

[0044] a. Weigh various raw materials, mix all auxiliary materials except walnuts, add 963.9kg of hot water at 95°C, stir evenly, and make soaking liquid;

[0045] b. heating and boiling the soaking feed liquid made in step a, and keeping boiling for 2 minutes to obtain the boiling feed liquid;

[0046] c. After the feed liquid stops boiling, add walnuts for soaking at 70°C for 12 hours;

[0047] d. Take out the soaked walnuts, centrifuge at 500 rpm for 20 minutes, then spread the walnuts on a mesh sieve with holes and let them stand for 7 hours at a temperature of 15°C and a humidity of 40% to control the water;

[0048] Packaging, sterilization and storage are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com