Optimal Welding Method and Structure of Gears and Combining Teeth

A technology combining teeth and gears, which is applied to welding equipment, workpiece edge parts, metal processing equipment, etc., can solve the problems that high-temperature air cannot be discharged and affects welding quality, and achieves simple and easy welding operations and quality inspections of welded parts, avoiding The effect of uneven weld depth and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

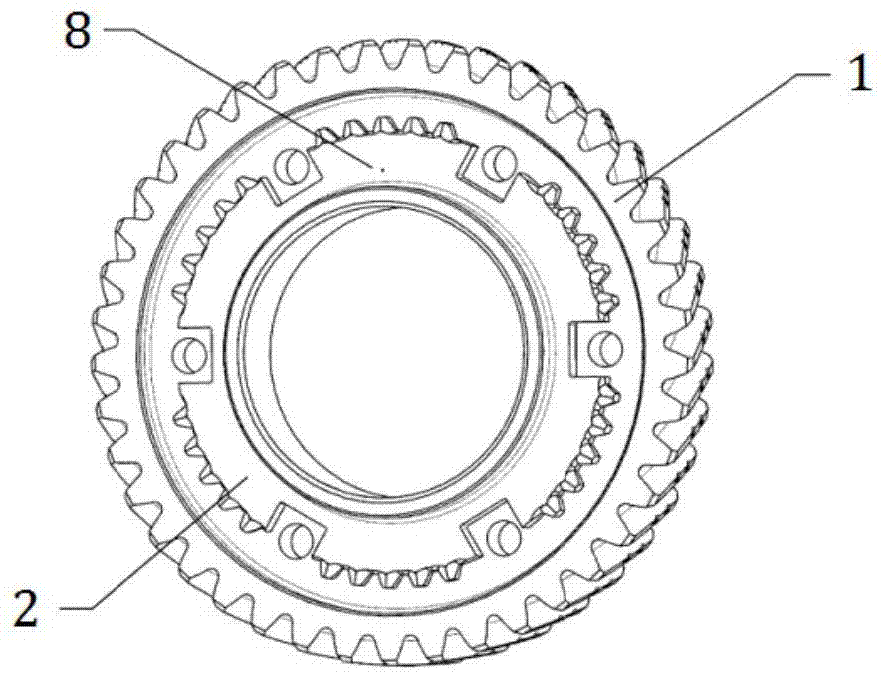

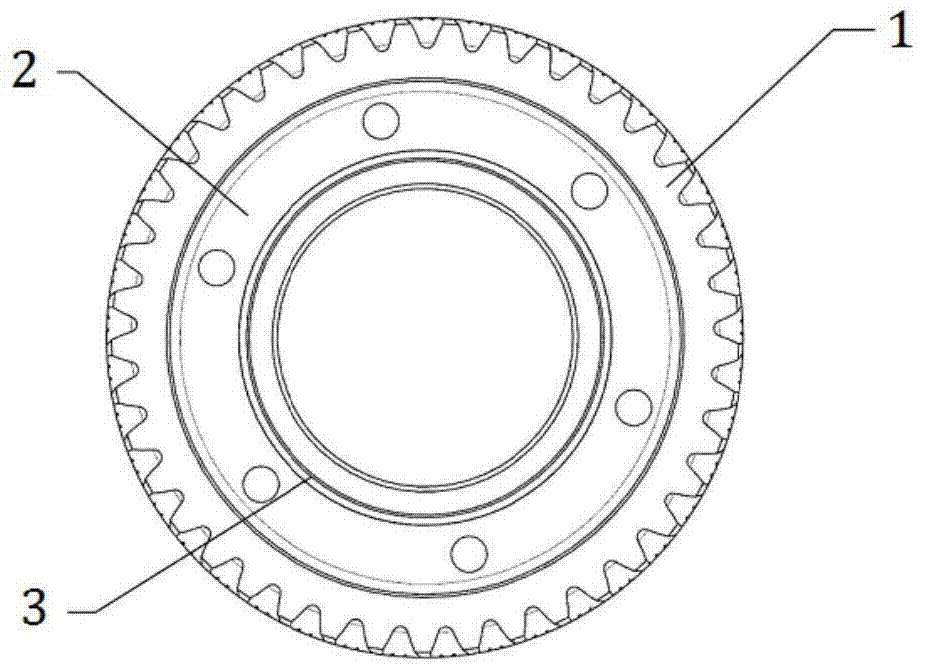

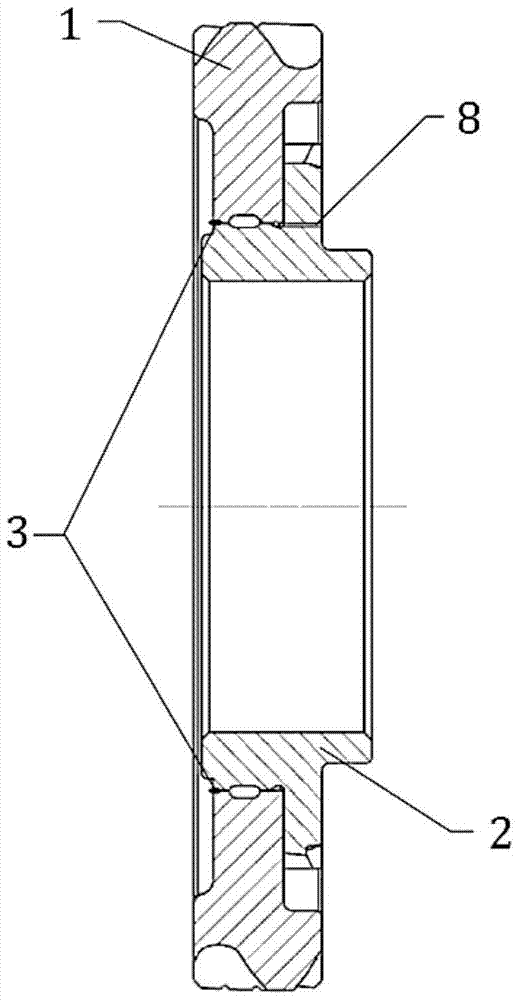

[0037] like Figure 1~3 As shown, this embodiment relates to a welding structure of gears and coupling teeth, including: an annular shift gear 1 with a gear portion and an engaging portion, and an annular coupling tooth 2 with a gear portion and a press-fit portion, wherein: the shift gear 1 The joint part b of the joint tooth 2 is an interference fit with the press-fit part a of the coupling tooth 2.

[0038] like Figure 4 As shown, the first annular groove 4 is provided on the joint part b of the gear gear 1, and the second annular groove 5 is provided on the press-fit part a of the coupling tooth 2. After the interference fit, the first annular groove The groove 4 and the second annular groove 5 form a first cavity.

[0039] The interference fit refers to: the joint part of the ring gear 1 and the ring coupling tooth 2 and the end face of the press-fit part are flush and form a ring-shaped junction, when laser welding or electron beam welding is performed to weld the jun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com