Fast demulsification flocculant for well cleanout truck of oil field

A flocculant and well-washing vehicle technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problems of wasting transport capacity and manpower, etc., achieve fast sedimentation speed, less dosage of chemicals, and good dehydration effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

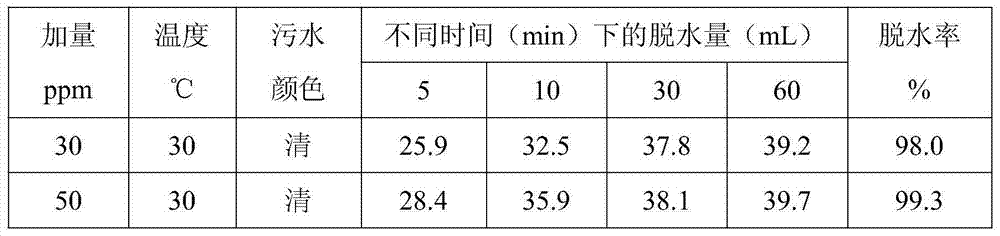

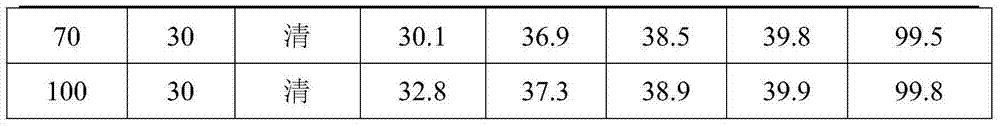

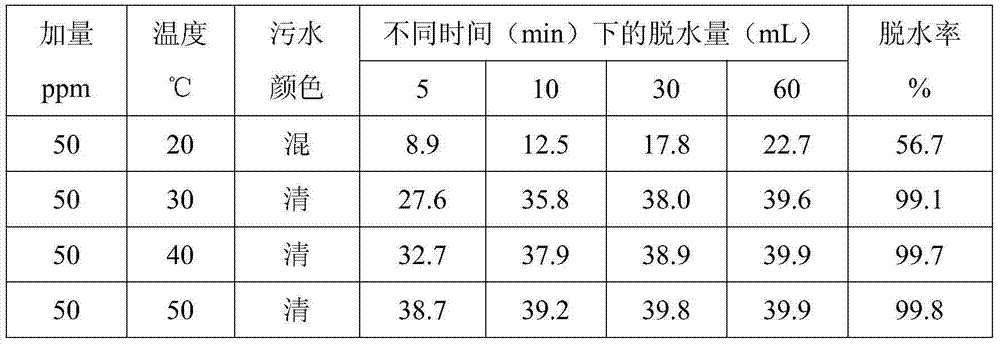

Examples

Embodiment 1

[0018] The rapid demulsification flocculant for oil field well washing vehicle of the present invention is composed of a dendritic nonionic demulsifier, a polymeric flocculant and a polymer composite ion sedimentation agent. The weight ratio of the dendritic non-ionic demulsifier, the polymeric flocculant and the polymer composite ion sedimentation agent is 1:1:0.1.

[0019] The dendritic nonionic demulsifier is polyethylene polyamine ethylene oxide propylene oxide polyether. The preparation method is as follows: select polyethylene polyamine and glycerin as the initiator, and KOH as the catalyst, add the initiator and the catalyst into a 0.5L high-pressure reactor, fully purge the pipeline and the reactor with nitrogen, stir and Heat up to 90°C, vacuumize and continue to heat up, stop vacuuming when it reaches 120°C (about 0.5 hours), add propylene oxide dropwise, and react at a temperature of 135±5°C and a pressure of 0.4MPa until the initiator and epoxy The ratio of ethane...

Embodiment 2

[0023] The rapid demulsification flocculant for oil field well washing vehicle of the present invention is composed of a dendritic nonionic demulsifier, a polymeric flocculant and a polymer composite ion sedimentation agent. The weight ratio of the dendritic non-ionic demulsifier, the polymeric flocculant and the polymer composite ion sedimentation agent is 1:5:1.

[0024] The dendritic nonionic demulsifier is polyethylene polyamine ethylene oxide propylene oxide polyether. The preparation method is as follows: select polyethylene polyamine and glycerin as the initiator, and KOH as the catalyst, add the initiator and the catalyst into a 0.5L high-pressure reactor, fully purge the pipeline and the reactor with nitrogen, stir and Heat up to 90°C, vacuumize and continue to heat up, stop vacuuming when it reaches 120°C (about 0.5 hours), add propylene oxide dropwise, and react at a temperature of 135±5°C and a pressure of 0.4MPa until the initiator and epoxy The ratio of ethane t...

Embodiment 3

[0028] The rapid demulsification flocculant for oil field well washing vehicle of the present invention is composed of a dendritic nonionic demulsifier, a polymeric flocculant and a polymer composite ion sedimentation agent. The weight ratio of the dendritic non-ionic demulsifier, the polymeric flocculant and the polymer composite ion sedimentation agent is 1:3:0.5.

[0029] The dendritic nonionic demulsifier is polyethylene polyamine ethylene oxide propylene oxide polyether. The preparation method is as follows: select polyethylene polyamine and glycerin as the initiator, and KOH as the catalyst, add the initiator and the catalyst into a 0.5L high-pressure reactor, fully purge the pipeline and the reactor with nitrogen, stir and Heat up to 90°C, vacuumize and continue to heat up, stop vacuuming when it reaches 120°C (about 0.5 hours), add propylene oxide dropwise, and react at a temperature of 135±5°C and a pressure of 0.4MPa until the initiator and epoxy The ratio of ethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com