Charcoal-based molybdenum fertilizer capable of reducing nitrate content of vegetables

A technology of nitrate content and biochar, applied in ammonium salt fertilizer, nitrogen fertilizer, organic fertilizer, etc., can solve the problems of complex formula and unsatisfactory effect of reducing nitrate, so as to increase vegetable yield, benefit plant growth, and improve soil The effect of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

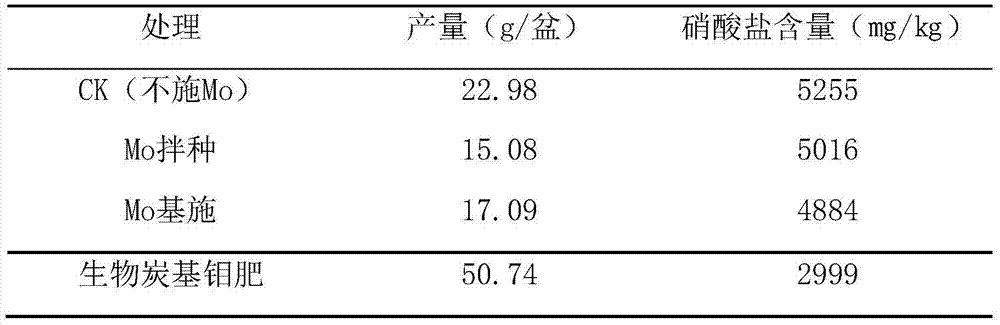

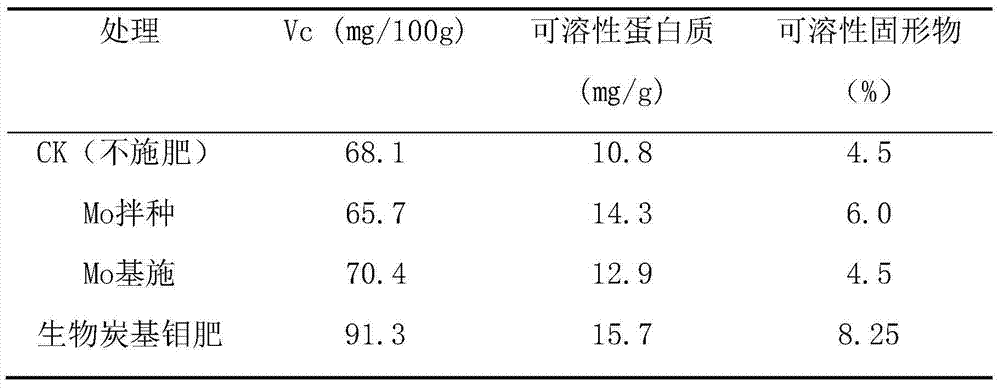

Examples

Embodiment 1

[0017] A biochar-based molybdenum fertilizer that can reduce the nitrate content of vegetables is composed of the following components: 10㎎ ammonium molybdate, 2㎏ gramineous crop stem biochar, and 6㎏ active silicon fertilizer.

[0018] Preparation method: Both the gramineous crop stem biochar and the active silicon fertilizer pass through a 1mm mesh, and 10g of ammonium molybdate is dissolved in 10L of water to form a 100㎎ / L ammonium molybdate solution. Because the content of molybdenum is very small, it can be better mixed with biochar when added to water. After mixing 100ml of the above ammonium molybdate solution with 2L of water, add 2㎏ gramineous crop stem biochar, and after 24 hours of adsorption equilibrium, 60 Dry in a constant temperature blast drying oven, add 6kg of active silicon fertilizer, and mix well.

Embodiment 2

[0020] A biochar-based molybdenum fertilizer that can reduce the nitrate content of vegetables is composed of the following components: 30㎎ ammonium molybdate, 2㎏ gramineous crop stem biochar, and 6㎏ active silicon fertilizer.

[0021] Preparation method: Both the gramineous crop stem biochar and the active silicon fertilizer pass through a 1mm mesh, and 10g of ammonium molybdate is dissolved in 10L of water to form a 100㎎ / L ammonium molybdate solution. Take 300ml of the above-mentioned ammonium molybdate solution, add 2L of water, and after mixing, add 2kg of gramineous crop stem biochar, after 24 hours of adsorption equilibrium, dry it in a constant temperature blast drying oven at 60°C, then add 6kg of active silicon fertilizer, and mix well .

Embodiment 3

[0023] A biochar-based molybdenum fertilizer that can reduce the nitrate content of vegetables is composed of the following components: 60㎎ ammonium molybdate, 2㎏ gramineous crop stem biochar, and 6㎏ active silicon fertilizer.

[0024] Preparation method: Both the gramineous crop stem biochar and the active silicon fertilizer pass through a 1mm mesh, and 10g of ammonium molybdate is dissolved in 10L of water to form a 100㎎ / L ammonium molybdate solution. Take 600ml of the above-mentioned ammonium molybdate solution, add 2L of water, and after mixing, add 2kg of gramineous crop stem biochar, after 24 hours of adsorption equilibrium, dry it in a constant temperature blast drying oven at 60°C, then add 6kg of active silicon fertilizer, and mix well .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com