Method for synthesizing diethylaminoethanol

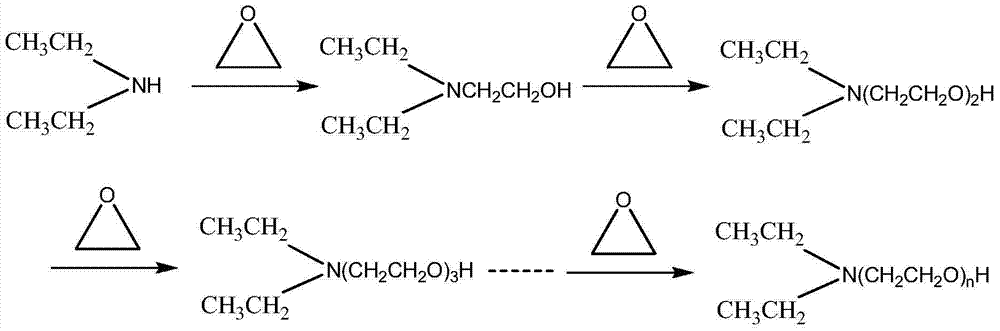

A technology of diethylaminoethanol and diethylamine, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxy compounds, etc., can solve the difficulty of affecting the color of products, the difficulty of separation and purification of diethylaminoethanol products, and the removal of In addition to other problems, it can reduce the energy consumption of rectification, improve the selectivity, and achieve the effect of light color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

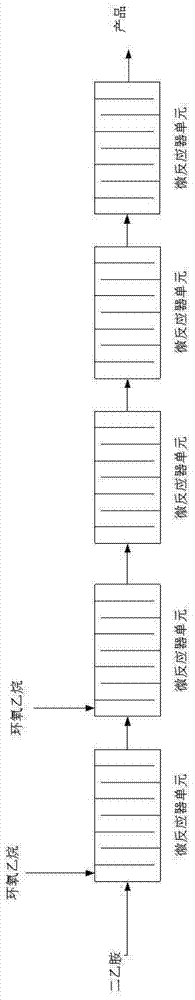

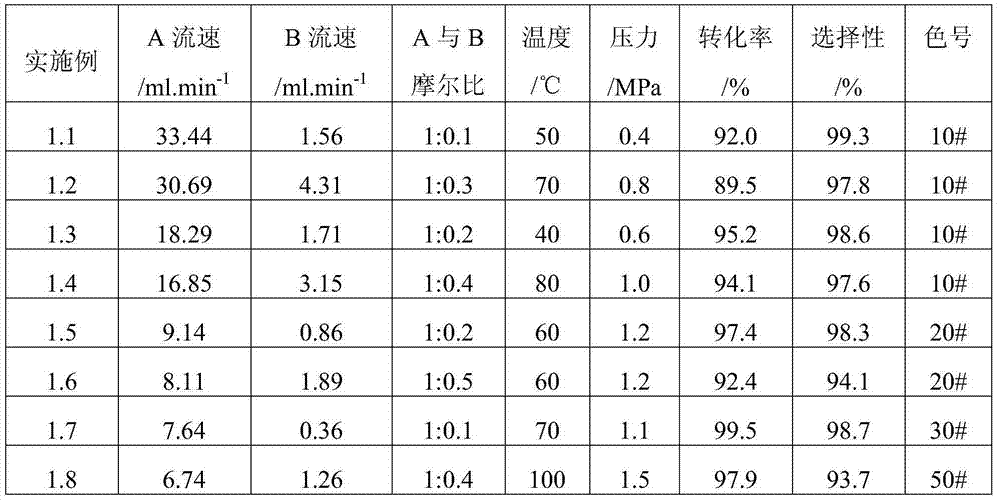

[0034] In the microreactor (containing two inlets) connected in series with five microreactor units, diethylamine is used as fluid A, and ethylene oxide is used as fluid B, and the two are mixed and reacted in the microreactor. The microreactor is placed in a bath at a certain temperature, the temperature is adjusted through the outer wall of the microreactor unit, and the pressure of the reaction system is adjusted through the back pressure valve. The microreactors of Examples 1.1 to 1.10 comprise a reaction zone of 20 ml and have a minimum cross-sectional equivalent diameter of 0.05 mm. Fluid A was added from the first microreactor unit, and fluid B was added from the first and second microreactor units at an equal flow rate, and the conversion rate and The selectivity of diethylaminoethanol (calculated by the area normalization method), finally obtains the diethylaminoethanol product through decompression degassing. The specific experimental conditions and results are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com