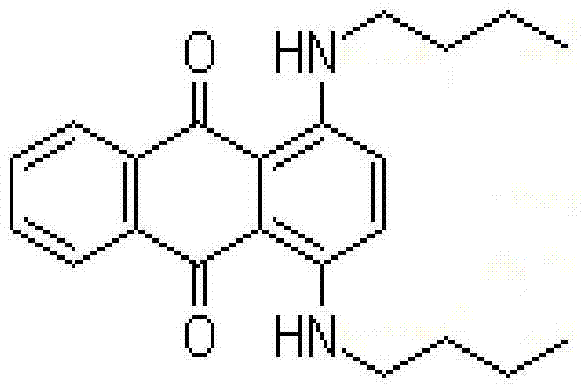

Method for preparing solvent blue 35

A solvent, dihydroxyanthraquinone technology, applied in the field of preparation of solvent blue 35, can solve the problems of low reaction yield, difficult to guarantee product quality, high by-products and tar, and achieves improving the reaction speed, reducing the generation of tar, Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

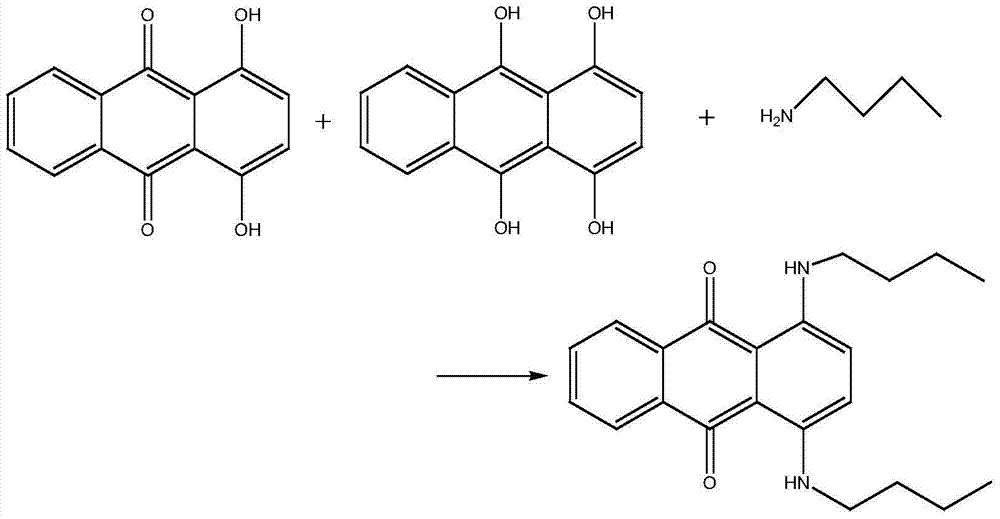

Method used

Image

Examples

Embodiment 1

[0020] In a 500ml four-necked bottle with mechanical stirring and a thermometer, add 150g of ethanol, 15g of anhydrous sodium sulfate, 20g of 1,4-dihydroxyanthraquinone, 4.5g of 1,4-dihydroxyanthraquinone leucosome, 5g of acetic acid, 30 g of butylamine was dropped into the reactor, the reactor was sealed, and the temperature was raised to reflux for reaction for 4 hours. After the reaction, part of 100g of ethanol and n-butylamine mixed solvent was evaporated, separated by adding 15wt% sodium hydroxide aqueous solution, filtered, washed, and dried to obtain 35.5g of solvent blue 35, with a content of 97.8% and a yield of 95.3%.

Embodiment 2

[0022] In a 500ml four-necked bottle with mechanical stirring and a thermometer, add 200g of ethanol, 20g of anhydrous sodium sulfate, 20g of 1,4-dihydroxyanthraquinone, 6g of 1,4-dihydroxyanthraquinone leuco, 8g of acetic acid, n-butyl 40 g of amine was put into the reactor, the reactor was sealed, and the temperature was raised to reflux for 2 hours. After the reaction, part of 160g of ethanol and n-butylamine mixed solvent was evaporated, separated by adding 15wt% sodium hydroxide aqueous solution, filtered, washed and dried to obtain 35.5g of solvent blue 35 with a content of 97.6% and a yield of 95.1%.

Embodiment 3

[0024] In a 500ml four-necked bottle with mechanical stirring and a thermometer, add 150g of ethanol, 20g of anhydrous sodium sulfate, 20g of 1,4-dihydroxyanthraquinone, 5g of 1,4-dihydroxyanthraquinone leuco, 5.8g of acetic acid, 50 g of butylamine was dropped into the reactor, the reactor was sealed, and the temperature was raised to reflux for 1 hour. After the reaction, part of 120g of ethanol and n-butylamine mixed solvent was evaporated, separated by adding 15wt% sodium hydroxide aqueous solution, filtered, washed, and dried to obtain 35.1g of solvent blue 35, with a content of 98.6% and a yield of 95.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com