Preparation method for polymer film for food contact in migration test

A polymer film and food contact technology, which is applied in the field of preparation of polymer films for food contact, can solve the problems of small additive content, uneven distribution of additive content, low mixing uniformity of additive and polymer pellets, etc. Uniform distribution, fast film formation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

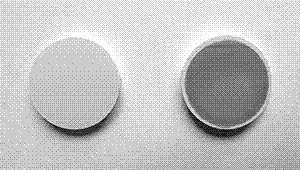

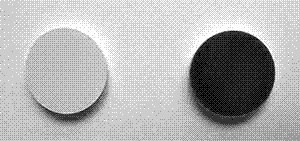

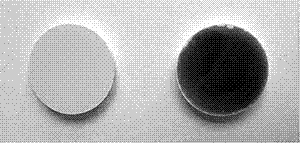

Image

Examples

Embodiment 1

[0033] Weigh 10 grams of polystyrene pellets and add them to a 250ml conical flask with a stopper, then add 100ml of toluene and shake well. After about 24 hours, after the polystyrene pellets are completely dissolved in toluene, weigh 0.2 grams The oxygen indicator platinum octaethylporphyrin (PtOEP) was added to the above polystyrene toluene solution, and a mixed solution was formed after it was completely dissolved. Take a polymer composite septum with a diameter of 2 cm and place it horizontally on the platform, accurately absorb 0.5 ml of the mixed solution with a straw, and slowly add it dropwise on the polymer composite septum. Spread out on the polymer composite cadmium pad to form a solution layer with uniform thickness. The polymer composite spacer covered with the mixed solution layer is placed in the atmospheric environment, and after the organic solvent in the mixed solution layer evaporates to dryness, the preparation of the polymer film containing the migration ...

Embodiment 2

[0035] Weigh 5 grams of polyvinyl chloride pellets and add them to a 250 ml conical flask with a stopper, then add 100 ml of tetrahydrofuran and shake well. After about 18 hours, after the polyvinyl chloride pellets are completely dissolved in tetrahydrofuran, weigh 0.2 Add the time-temperature indicator spiropyran (SP) of 1 g into the above-mentioned polyvinyl chloride tetrahydrofuran solution, and form a mixed solution after being completely dissolved. Take a polymer composite spacer with a diameter of 2 cm and place it on the rotating platform in the spin coater, then add 0.5 ml of mixed solution in the spin coater, start the spin coater, and control the rotation speed of the spin coater so that the spray coating is in the polymerization state. The mixed solution on the composite septum just covers the entire septum. After the spin coating is completed, the polymer composite spacer is placed in the atmospheric environment, and after the organic solvent in the mixed solution...

Embodiment 3

[0037] Weigh 10 grams of polyethersulfone pellets and add them to a 250 ml conical flask with a stopper, then add 100 ml of chloroform and shake well, and wait for about 24 hours after the polyethersulfone pellets are completely dissolved in chloroform, Weigh 0.2 g of the time-temperature indicator spirooxazine (SO) and add it to the polyethersulfone chloroform solution, and form a mixed solution after being completely dissolved. Weigh 10 g of polyethersulfone pellets and add to another 250 ml conical flask with a stopper to prepare a pellet solution. Take a polymer composite septum with a diameter of 2 cm and place it horizontally on the platform, accurately draw 0.5 ml of the mixed solution with a straw, and slowly add it dropwise on the polymer composite septum. After the addition is completed, a mixed solution layer will be spread. The polymer composite spacer is placed in the atmosphere, and after the organic solvent in the mixed solution layer evaporates to dryness, draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com