A kind of pullulanase enzyme-producing strain and the method for improving its enzyme-producing ability

A technology of pullulanase and bacterial strains, applied in the field of bioengineering, can solve the problems of unrealized industrial production, difficulty in meeting urgent needs, low enzyme activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

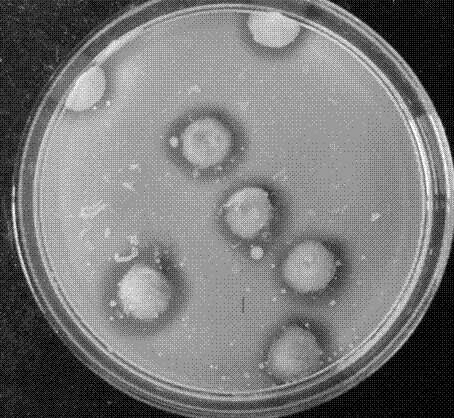

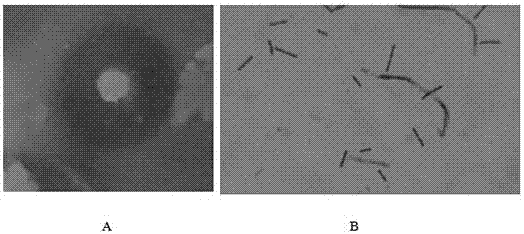

[0052] The pullulanase engineered bacterium constructed in the present invention is Klebsiella mutabilis HN7 ( Klebsiella variicola HN7) is the original starting strain, which was screened from the soil near the starch production plant. It has been preserved in the General Microbiology Center (Beijing) of the China Committee for the Collection of Microbial Cultures on January 14, 2015. The preservation number is: CGMCC NO .10357.

[0053] The following is a brief introduction to the screening process of the bacteria.

[0054] screening method

[0055] The method of screening microorganisms from soil samples was used for screening. The soil samples were taken from different starch factories and production starch pool annexes in many provinces and cities in China.

[0056] Media used during screening

[0057] Strain enrichment screening medium (mass%): glutinous rice flour 1.0, peptone 0.5, yeast extract 0.5, KH 2 PO 4 0.05, MgSO 4 .7H 2 O 0.01, KH 2 PO 4 0.05, ag...

Embodiment 2

[0100] The high-yield pullulanase engineering bacterium constructed in this embodiment is Klebsiella mutabilis HN7 ( Klebsiella variicola HN7) is the original starting strain, which was constructed using the following steps:

[0101] (1) Extract DNA, amplify and culture Bacillus subtilis in LB medium, culture at 30°C, 220 rpm for 15 h, centrifuge at 8000 r / min for 20 min to collect bacteria, and then follow Ezup column bacterial genomic DNA Extract the DNA of the cultured bacteria according to the instructions of the extraction kit.

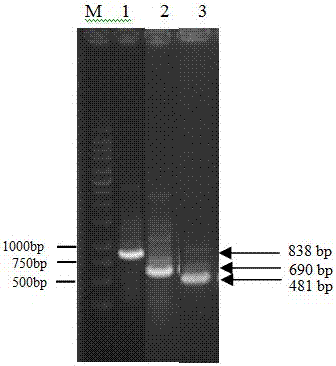

[0102] (2) PCR amplification, PCR amplification of tetracycline resistance gene Tet upstream fragment 、 tetracycline resistance gene Tet Downstream fragment, Bacillus subtilis P43 promoter, specifically as follows:

[0103] PCR amplification of tetracycline resistance gene Tet For upstream fragments, the primer sequences are designed as follows:

[0104] Primer Tet-F1 of the upstream fragment: 5'-GGGGGATGATTGCGCCCCGGAAAGCAAAAATATCTAA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com