Pre-treatment method for simultaneously determining rare-earth elements and lead of tea leaves

A rare earth element and tea technology, applied in the field of analytical chemistry, can solve the problems of volatile element loss crucible, occlusion, and many operation steps, and achieve the effects of simplifying pretreatment steps, reducing detection costs, and simple digestion steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

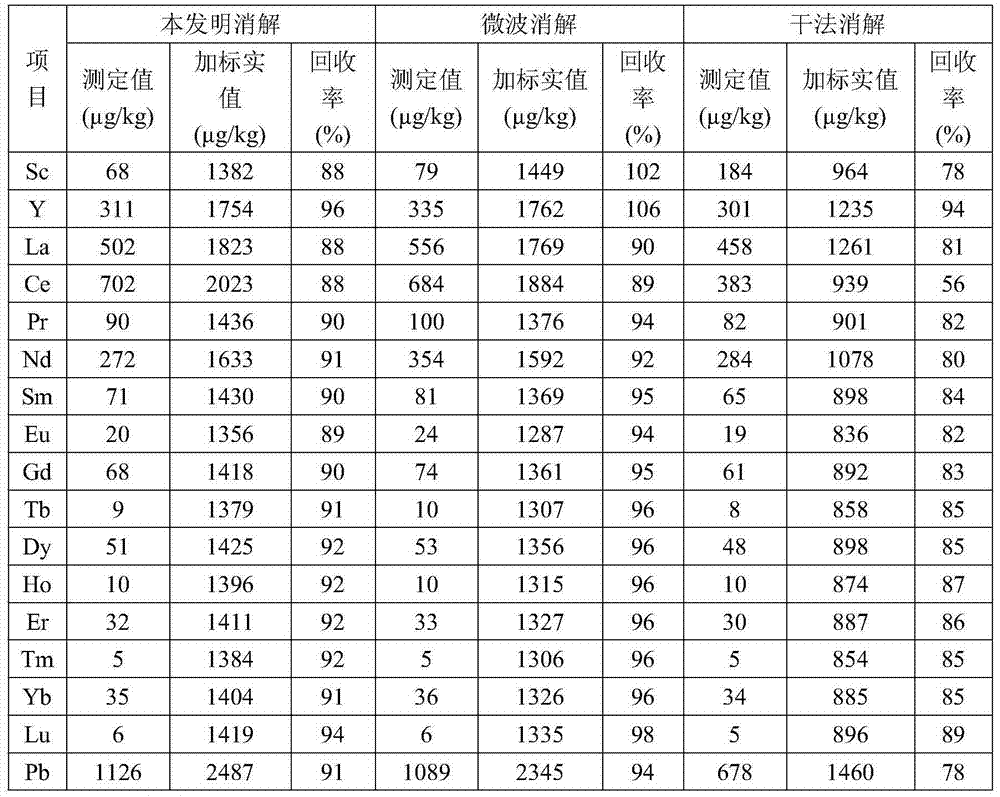

[0034] Determination of Recovery Rate of Rare Earth Elements and Lead Elements in Tea

[0035] 1. Preparation of Blank Solution

[0036] Except that no sample is added, the other steps are the same as step 3.

[0037] 2. Sample spiking

[0038] The laboratory selected the same tea sample, weighed 2 groups of samples, and each group had 3 parallel samples, one of which was measured by adding a mixed standard solution of 16 rare earth elements and lead, so as to obtain the recovery rate of rare earth elements and lead elements.

[0039] 3. Preparation of sample digestion solution

[0040] 3.1 Pre-digestion stage: Weigh 0.4g (accurate to 0.0001g) of the tea sample and place it in a polytetrafluoroethylene crucible, add 8mL nitric acid into the polytetrafluoroethylene crucible in a fume hood, cover it, and let it stand overnight;

[0041] 3.2 Nitric acid digestion stage: After the pre-digestion stage, heat it on an electric heating plate in a fume hood at 200°C for 3 hours;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com