Novel driving lens and manufacture method thereof

A manufacturing method and lens technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of insufficient driving, insufficient strong light blocking, insufficient light transmittance control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing a novel driving lens. The steps are as follows:

[0045] 1. Obtaining the substrate:

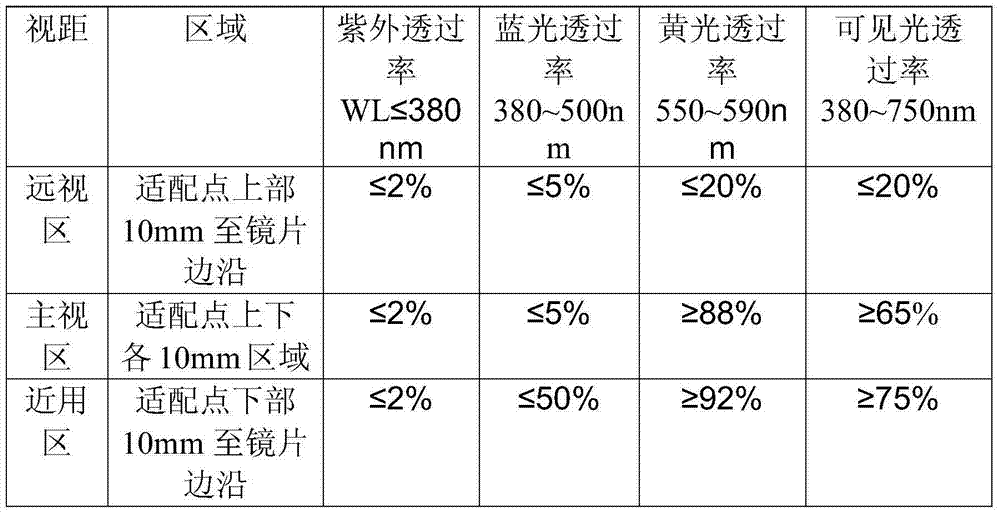

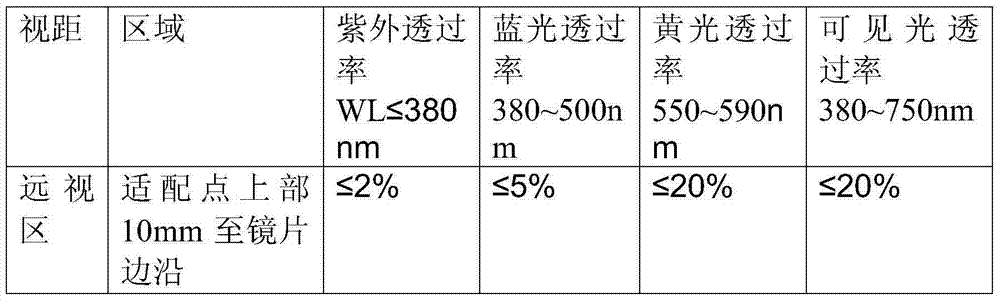

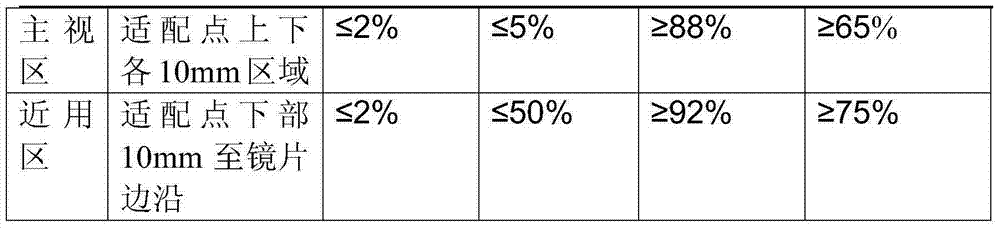

[0046] a. Use rubber ring (or tape) and glass mold to close the mold, add IPP initiator, ultraviolet absorber, melanin solution in a certain proportion to the allyl diethylene glycol carbonate monomer, stir to prepare, and pour until it has been combined In a good glass mold, after 20 hours of non-linear curve curing, the glass mold and the preliminary formed lens are separated, and the substrate (1) is obtained after cleaning and secondary curing; test and adjust the content of melanin and ultraviolet absorber to meet the following conditions :T550 (transmittance of visible light with wavelength of 550nm and greater than 550nm, the same below) of the substrate should be greater than 85%, T450 (transmittance of wavelength 450nm, the same below)) should be less than 75%, Tsb (380nm~500nm blue light transmittance) Excess rate) shoul...

Embodiment 1

[0065] Example 1: C39 new driving lens

[0066] 1. Using EVA rubber ring and 500-bend glass mold to close the mold, add allyl diethylene glycol carbonate monomer IPP 84.2 parts, initiator IPP 2.8 parts, UV absorber 6 parts, and melanin solution 7 parts according to the following proportions. , Mixing and preparing, pouring into the already closed glass mold, after 20 hours of non-linear heating and curing, separating the glass mold and the preliminary formed lens, cleaning and secondary curing to obtain the substrate (1-1).

[0067] 2. Prepare the basic dyeing solution with OMS BLUEBLOCKER dyeing solution as the main material, and then heat the dyeing solution to a constant temperature of 92~95 degrees, first clean the substrate (1-1), and put all of the substrate into the color tank. Single color, control the dyeing temperature at 90-95 degrees Celsius, control the dyeing time for about 10 minutes, adjust the color solution concentration, temperature and time to obtain the substra...

Embodiment 2

[0078] Example 2: PC new driving lens

[0079] 1. Select optical grade PC raw material, mix with UV absorber, and obtain the unhardened lens through injection molding to obtain the substrate (2-1), test and adjust the content of UV absorber to meet the following conditions: T550( The transmittance of visible light with a wavelength of 550nm and greater than 550nm, the same below) should be greater than 85%, and Tuv (ultraviolet (UVA\UVB and UVC transmittance, the same below)) should not be greater than 2%.

[0080] 2. Prepare the basic dyeing solution with OMS's BLUEBLOCKER dyeing solution as the main material, and then heat the dyeing solution to a constant temperature of 92~95 degrees, first clean the substrate (2-1), and put all of the substrate into the color tank. Monochromatic, get the substrate (2-2), control the dyeing temperature at 90-95 degrees Celsius, control the dyeing time to be greater than 5 minutes, adjust the concentration, temperature and time of the color solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com